A method of naturally dyeing fibers using carotenoids

A technology of carotene and use, which is applied in the field of natural dyeing, can solve the problems of oxygen, heat and light instability, and less application, and achieve the effect of low price, high extraction efficiency, and no burden on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

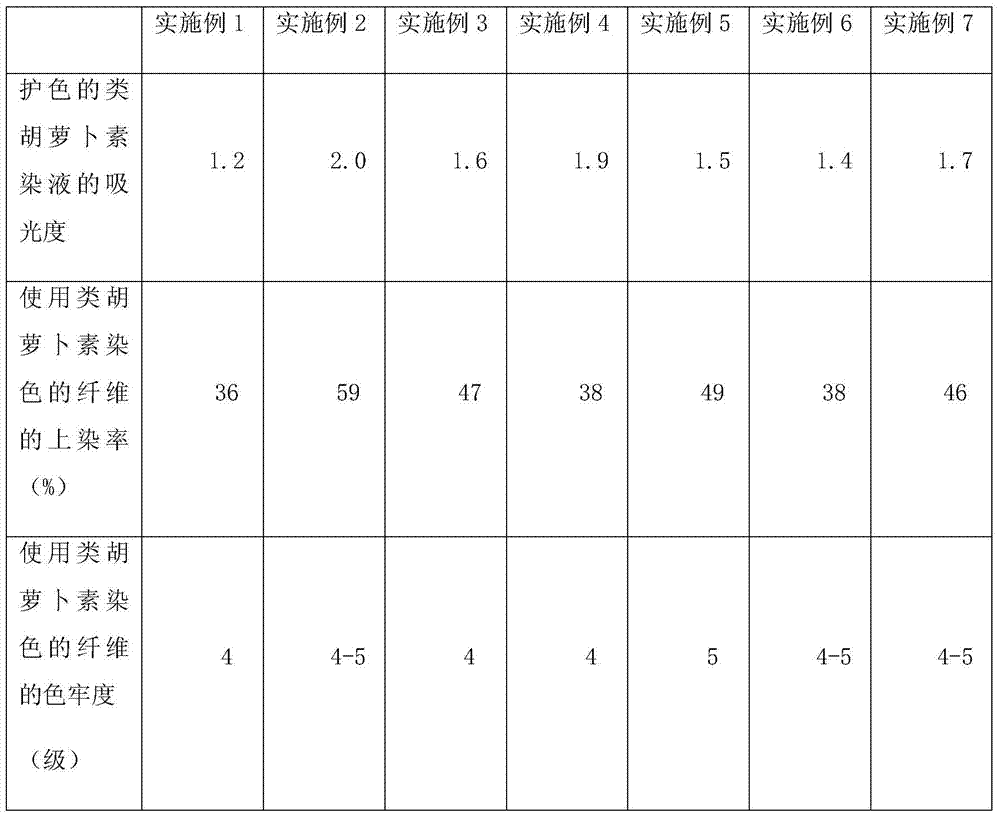

Examples

Embodiment 1

[0027] (1) Wash fresh carrots, tomatoes and gardenias with a weight ratio of 1:0.5:0.3, blanch them in water at 95°C for 30s to inhibit the activity of enzymes, take them out to dry, cut into pieces and smash them to form a mud-like substance , put the muddy material in a supercritical carbon dioxide equipment, at 250kg / cm 2 96% of carotenoids are extracted to obtain a carotenoid extract under the pressure and temperature of 50°C.

[0028] (2) the carotenoid extract prepared by step (1) is placed in the solution of 0.1mol / L monovalent sodium ion and divalent magnesium ion, wherein the mol ratio of monovalent sodium ion and divalent magnesium ion is 1 : 1, stir to form a mixed solution, adjust the pH value of the mixed solution to 10 with a citric acid solution, and obtain a carotenoid dye solution with a carotenoid content of 75% for color protection.

[0029] (3) With a bath ratio of 1:50, the protein fibers pretreated by plasma technology were immersed in the color-protecti...

Embodiment 2

[0031] (1) Wash fresh carrots, tomatoes and gardenias with a weight ratio of 1:1:0.7, blanch them in water at 100°C for 30s to inhibit the activity of enzymes, take them out to dry, cut into pieces and smash them to form a mud-like substance , put the muddy substance in a supercritical carbon dioxide equipment, at 300kg / cm 2 The carotenoid extract is obtained by extracting 98% of carotenoids under the pressure of 55°C.

[0032] (2) the carotenoid extract prepared by step (1) is placed in the solution of 0.3mol / L monovalent sodium ion and divalent magnesium ion, wherein the mol ratio of monovalent sodium ion and divalent magnesium ion is 1 : 1, stir evenly to form a mixed solution, adjust the pH value of the mixed solution to 11 with a citric acid solution, and obtain a color-protecting carotenoid dye solution with a carotenoid content of 80%.

[0033] (3) With a bath ratio of 1:50, the protein fibers pretreated by plasma technology were immersed in the color-preserving carote...

Embodiment 3

[0035] (1) Wash fresh carrots, tomatoes and gardenias with a weight ratio of 1:0.6:0.5, blanch them in water at 95°C for 30s to inhibit the activity of enzymes, take them out to dry, cut into pieces and smash them to form a mud-like substance , put the muddy material in a supercritical carbon dioxide equipment, at 280kg / cm 2 97% carotenoid is extracted to obtain a carotenoid extract under the pressure and 52°C temperature.

[0036] (2) the carotenoid extract prepared by step (1) is placed in the solution of 0.2mol / L monovalent sodium ion and divalent magnesium ion, wherein the mol ratio of monovalent sodium ion and divalent magnesium ion is 1 : 1, stir evenly to form a mixed solution, adjust the pH value of the mixed solution to 10.5 with a citric acid solution, and obtain a color-protecting carotenoid dye solution with a carotenoid content of 77%.

[0037](3) With a bath ratio of 1:50, the cellulose fibers pretreated by plasma technology were immersed in the color-protecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com