Low-temperature ferrite LT-FH40 steel plate applied to hot-rolled ships and production method thereof

A technology of LT-FH40 and production method, applied in the field of iron and steel, can solve the problems of complex rolling process, difficult to meet the requirements of thickness and performance, increase cost, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a hot-rolled marine low-temperature ferritic LT-FH40 steel plate, which contains the components in the following table (1), and the remaining content is Fe and unavoidable impurities.

[0022] (1) Chemical composition (%)

[0023] steel type

C

mn

Si

P

S

Nb

Alt

Ti

Ni

Ceq

LT-FH40

0.04

1.35

0.10

0.006

0.003

0.010

0.02

0.007

0.25

0.29

[0024] The refinement of austenite grains can be controlled by the second phase precipitates, which are usually achieved by adding alloying elements such as Nb and Ti, which can form carbon, nitrogen or carbonitride precipitation during the cooling process of the steel. During the austenitization process of steel, the grain boundaries are pinned, thereby inhibiting the growth of austenite grains. Controlling the niobium-titanium content within a certain range not only does not have a harmful effect on the strength ...

Embodiment 2

[0034] Present embodiment LT-FH40 steel plate comprises following table (1-1) component

[0035] (1-1) Chemical composition (%)

[0036] steel type

Embodiment 3

[0038] Present embodiment LT-FH40 steel plate comprises following table (1-2) component

[0039] (1-3) Chemical composition (%)

[0040] steel type

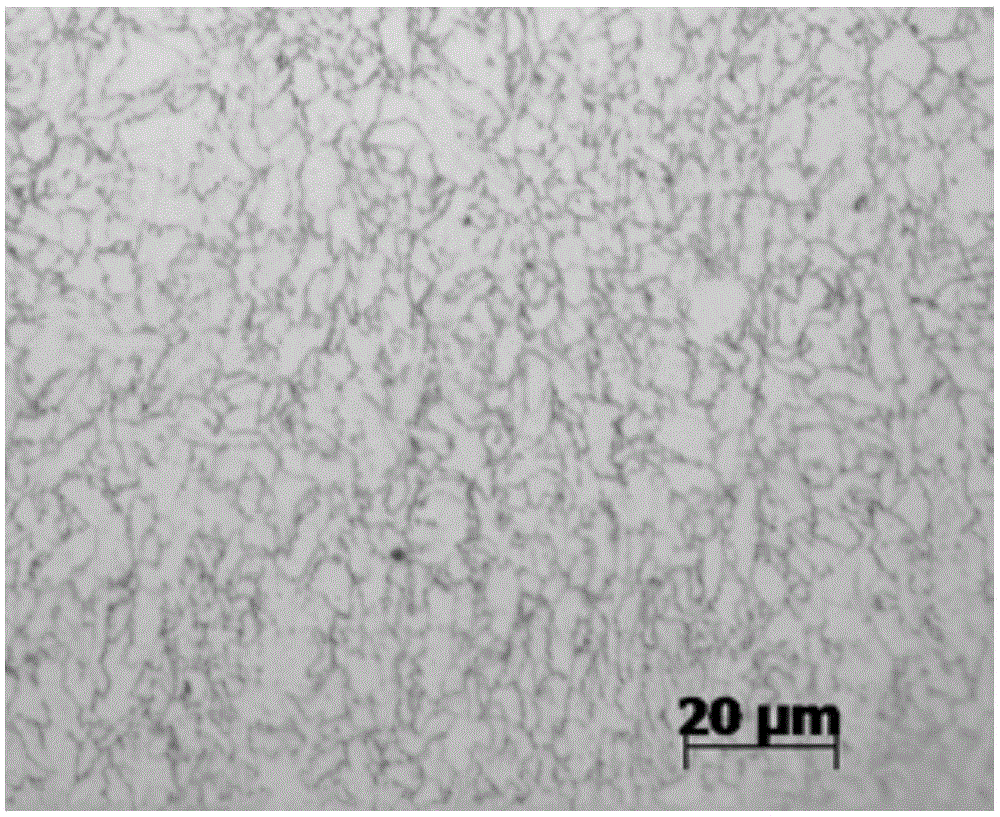

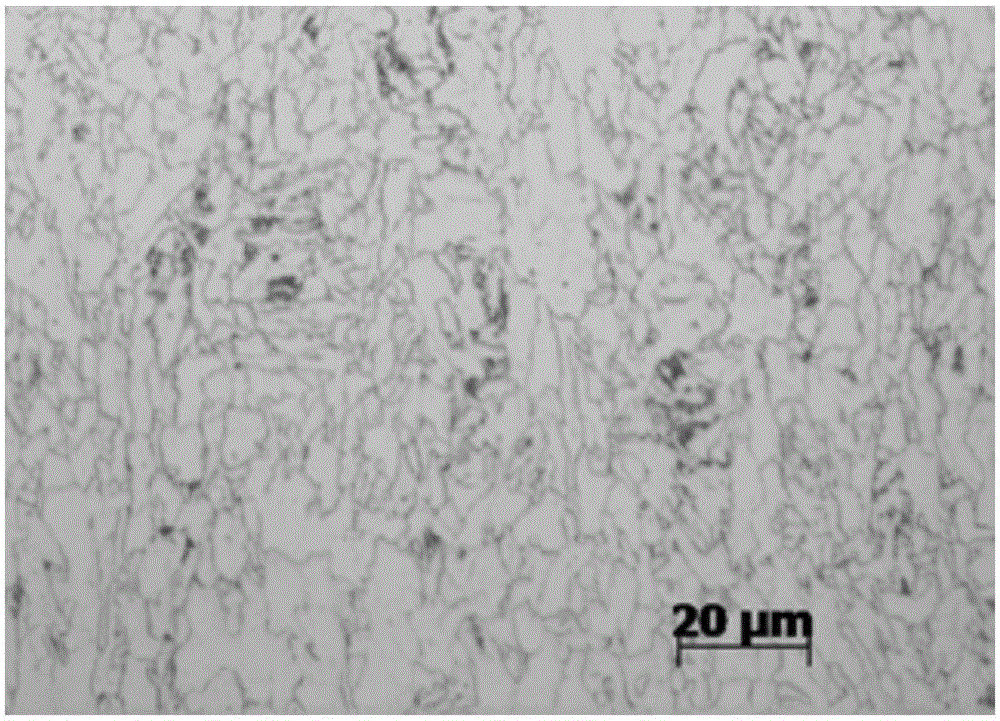

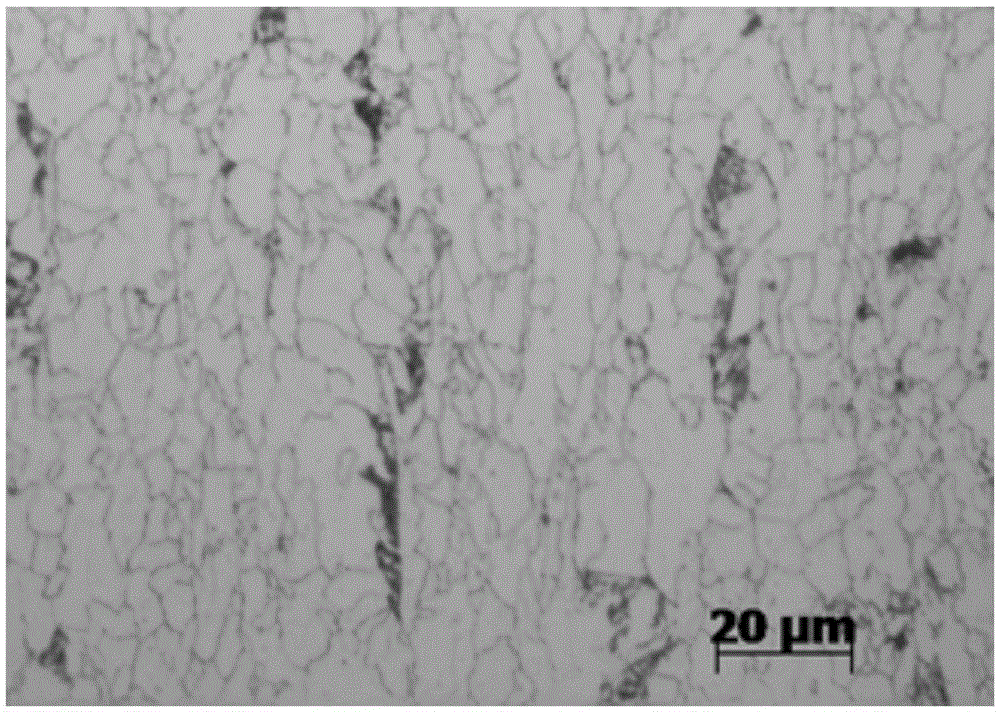

[0041] Compared with Example 1, Examples 2 and 3 have different chemical composition ratios; however, the production process is basically the same, so details are not repeated here. Through the composition design of low-carbon and niobium-titanium alloying, the schematic diagram of the metallographic structure of the obtained steel plate is as follows Figure 1-3 shown. Using two-stage controlled rolling technology in the austenite recrystallization zone and austenite non-recrystallization zone, the rough rolling single-pass reduction rate is greater than 15% to break the austenite grains, and the rough rolling finish rolling temperature is controlled at 1000°C; The starting temperature of finish rolling is controlled to be ≤840°C, and the cumulative reduction rate of the last three passes of finish rolling is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com