Method for preparing collagen through high-pressure enzymolysis

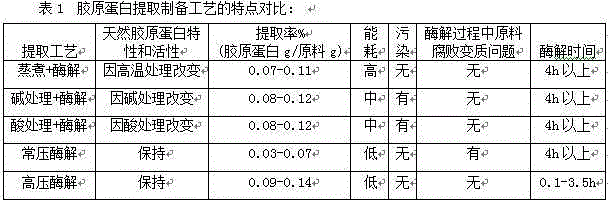

A collagen and high-pressure enzyme technology, applied in the field of bioengineering, can solve the problems of low collagen production rate, reduced activity, and environmental pollution, and achieve the effects of shortening the enzymatic hydrolysis time, increasing the extraction rate, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Pretreatment of raw materials: remove foreign matter from pigskin, dry, crush, and pass through a 30-mesh sieve;

[0014] (2) High-pressure enzymatic hydrolysis treatment: Take 10g of pigskin powder, disperse it in the bromelain solution at a ratio of 1:1 by weight of material to liquid (the amount of bromelain added is 7000U / g), add buffer solution to adjust to pH=4 , under the conditions of temperature 70°C and pressure 700Mpa for 0.1h;

[0015] (3) Separation treatment: the enzymatic hydrolysis product was subjected to solid-liquid separation to obtain collagen liquid; the collagen liquid was concentrated and dried to obtain 2.8 g of collagen powder.

Embodiment 2

[0017] (1) Raw material pretreatment: remove foreign matter from the chicken bone, dry it, crush it, and pass it through a 400-mesh sieve;

[0018] (2) High-pressure enzymatic hydrolysis treatment: take 10 g of chicken bone powder, disperse it in the pepsin solution at a ratio of 1:10 by weight of material to liquid (the amount of pepsin added is 1000 U / g), add buffer solution to adjust the pH to 2.2, Enzymolysis for 3.5 hours at a temperature of 30°C and a pressure of 100Mpa;

[0019] (3) Separation treatment: the enzymatic hydrolysis product was subjected to solid-liquid separation to obtain collagen liquid; the collagen liquid was concentrated and dried to obtain 0.9 g of collagen powder.

Embodiment 3

[0021] (1) Raw material pretreatment: remove foreign matter from cattle and sheep bones, dry, crush, and pass through a 40-mesh sieve;

[0022] (2) High-pressure enzymatic hydrolysis treatment: Take 10g of beef and sheep bone powder, disperse it in the papain solution with a weight ratio of 1:7 (the amount of papain added is 4000U / g), add buffer solution to adjust the pH =5, enzymatic hydrolysis for 3.5 hours at a temperature of 50°C and a pressure of 300Mpa;

[0023] (3) Separation treatment: the enzymatic hydrolysis product was subjected to solid-liquid separation to obtain collagen liquid; the collagen liquid was concentrated and dried to obtain 1.4 g of collagen powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com