Mutant of pectin lyase from Aspergillus niger and viscosity reducer of corn syrup in alcohol fermentation production

A technology of pectin lyase and mutants, which is applied in the field of pectin lyase mutants of Aspergillus niger and syrup viscosity reducers in corn alcohol fermentation production, which can solve the problem of raising drying temperature, prolonging high temperature residence time, and reducing corn Fuel ethanol enterprise profit and other issues, to achieve the effect of reducing steam consumption, excellent enzyme stability, excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation and properties of embodiment 1 Aspergillus niger pectin lyase mutant

[0029] 1. Sequence of the mutant

[0030] The amino acid sequence of Aspergillus niger (Aspergillus niger) pectin lyase is shown in SEQ ID NO: 1 (this sequence consists of 137 and 204 in the original sequence of Aspergillus niger pectin lyase (GenBank: AIE38009.1) of NCBI X is taken as K and D respectively), and the cDNA sequence of the gene is shown in SEQ ID NO:2.

[0031] After analysis by the molecular simulation software PROPKA software, the lysine (K) at position 241 of the amino acid sequence of Aspergillus niger pectin lyase was replaced with methionine (M) to obtain mutant K241M, and the codons were replaced accordingly. For Escherichia coli, using http: / / www.jcat.de Codon optimization was performed on the website, and finally the coding gene sequence of the mutant K241M was obtained, as shown in SEQ ID NO:3.

[0032] 2. Preparation of pectin lyase mutants from Aspergillus ni...

Embodiment 2

[0041] The preparation of embodiment 2 viscosity reducer

[0042] Viscosity reducers of the following compositions were prepared respectively. The parts in this embodiment are parts by mass. In this example, the original Aspergillus niger pectin lyase and the mutant K241M obtained the fermentation liquid according to the method in Example 1 respectively, and suspended the thallus in phosphate buffer to make OD 600Both were suspensions of 4.5, and the crude enzyme solution was obtained by ultrasonic crushing. The enzyme activities of the crude enzyme solution were 6.47IU / ml and 9.8IU / ml respectively. Purify according to the method in the literature (Cheng Lifeng et al., Construction of a pectin lyase gene (pel) expression system and the enzymatic properties of its expression product, Journal of Agricultural Biotechnology, 2013, 21 (5): 546-553) The pectin lyase was freeze-dried, and the purity of the purified original Aspergillus niger pectin lyase and the mutant K241M were f...

Embodiment 3

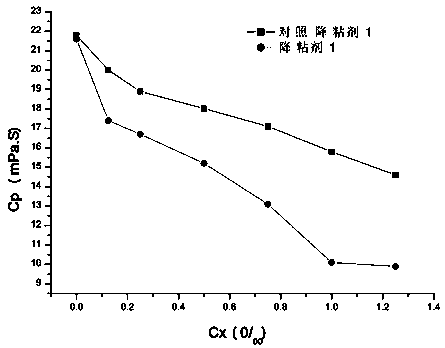

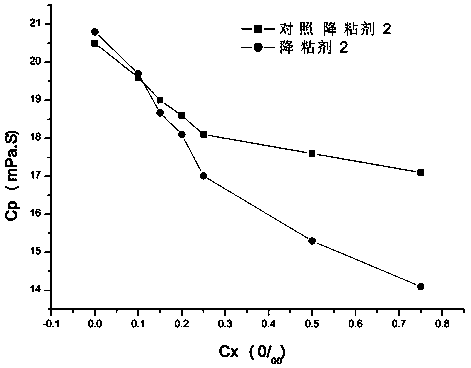

[0050] Application of embodiment 3 viscosity reducer

[0051] The technological process of corn alcohol fermentation is: corn flour—pulp mixing—adding enzyme preparation and yeast—raw meal fermentation—distillation—dehydration—fuel ethanol. The addition amount of each substance in the fermentation is 2kg of corn flour, 0.1-0.5% of yeast, 20-80U / g corn flour of alpha-amylase, and 100-200U / g corn flour of glucoamylase. Fermentation conditions: material-to-water ratio 1:2-1:5, constant temperature 28-35°C, stirring speed 100-200r / min, fermentation without cooking for 3-6 days. After the fermentation is finished, the fuel ethanol is distilled out, and the distillation waste mash is filtered to obtain a clear liquid. Concentrate the supernatant to a syrup with a concentration (mass percentage of dry matter, the same below) of 29%. Viscosity reducing agent 1 and comparison viscosity reducing agent 1, viscosity reducing agent 2 and comparison viscosity reducing agent 2 in Example 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com