A container for compounding expanded particles between inner and outer layers of film

A technology of composite foaming and foaming particles, which is applied to the container of composite foaming particles between the inner and outer layers of the film, the packaging container of disposable dishes or instant noodles, and can solve the problem of not being an environmentally friendly material, low acceptance, and strength. Insufficient and other problems, to achieve the effect of good thermal insulation function, improved structural strength, and stable structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

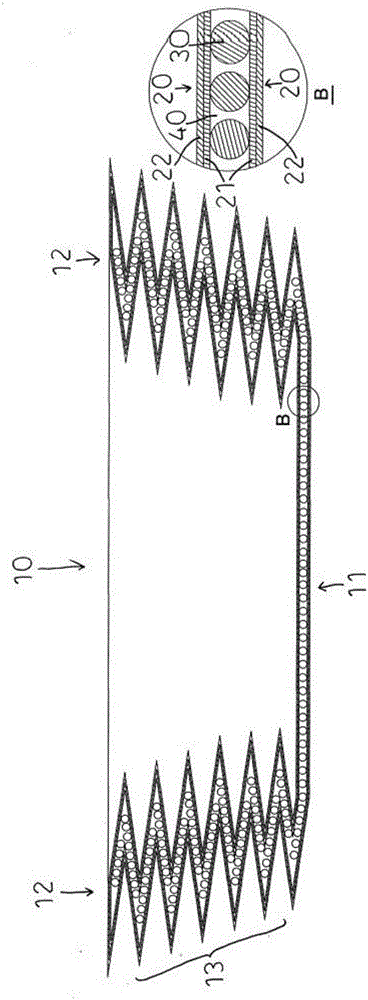

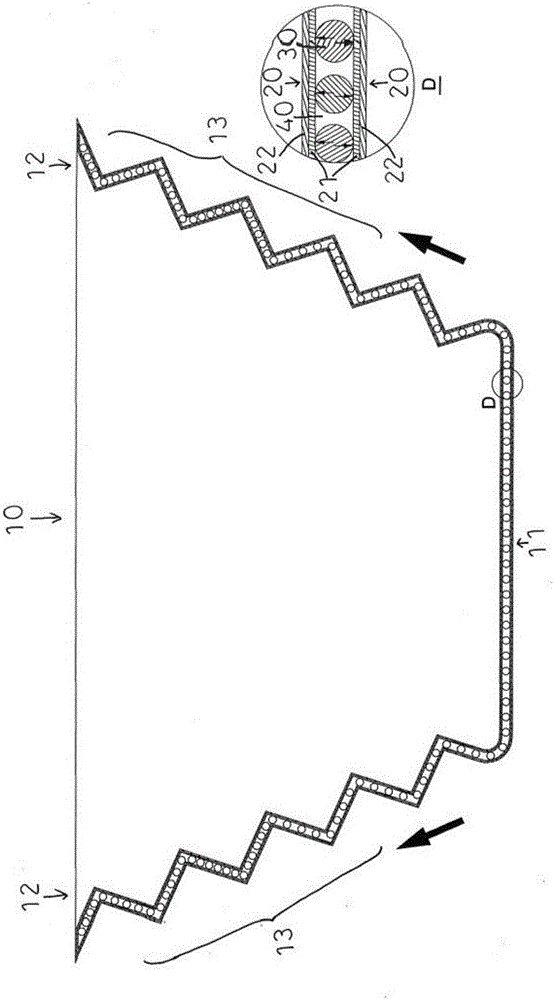

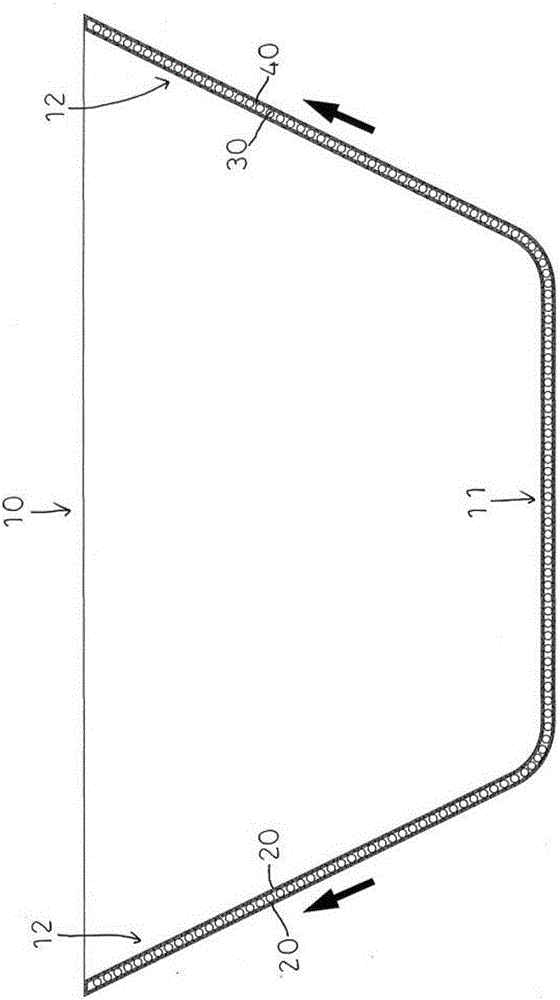

[0018] refer to figure 1 , figure 2 and image 3 The container 10 includes at least a bottom surface 11 and a wall surface 12 whose lower end is connected around the bottom surface 11. The wall surface 12 of the container 10 is provided with a plurality of foldable organ structures 13. The bottom surface 11 and the wall surface 12 are composed of two layers of film 20 and a small amount of A sealed thermal insulation space 40 is formed between the two layers of film 20. The layer of film 20 is co-extruded from the inner layer sheet 21 and the outer layer sheet 22. The foam particles 30 are made of It is loosely connected in the thermal insulation space 40 between the two films 20 .

[0019] The two-layer film 20 is an environment-friendly temperature-resistant polymer, and an environment-friendly material of polyethylene (PE), polypropylene (PP) or degradable polylactic acid (PLA) can be selected, polyethylene (PE) or polypropylene ( PP) is harmless to the human body, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com