Method for rapidly determining ash content of paper filled with porous calcium silicate

A porous calcium silicate and rapid determination technology, which is applied in the direction of weighing by removing certain components, can solve the problems of incomplete combustion of organic matter in paper, large temperature fluctuations, and needs, etc., to shorten the measurement time of ash content and the heating time long-term, accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

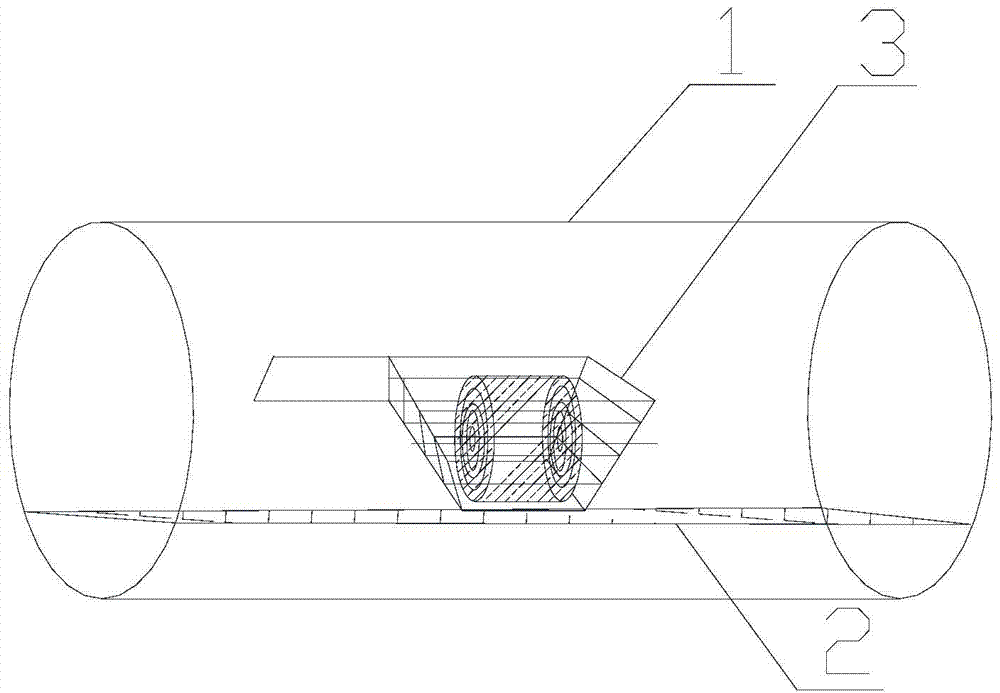

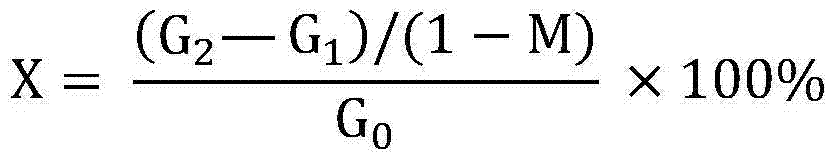

[0047] Porous calcium silicate filled electrostatic copy paper (quantitative 70g / m 2 ), take 0.5g of calcium silicate filled electrostatic copy paper and cut it into a number of paper strips with a length of 150mm and a width of 10mm, then overlap the paper strips and roll them into a cylindrical paper pattern along the length direction, with the gap between each layer being 1-5mm , after weighing the cylindrical paper sample and the burning device for placing the cylindrical paper sample with an analytical balance (0.0001g), put the cylindrical paper sample into the burning bracket 3 in the burning device, and ignite the cylindrical paper sample with a butane spray gun And ignite at high temperature for 3 minutes. After the residue is completely smoldering, cool in the air for 20 seconds, then place it in a desiccator for 3 minutes, then weigh it on an analytical balance, and finally obtain its ash value by calculation. Repeat several times. Calculate the average. Standard a...

Embodiment 2

[0051] Porous calcium silicate laboratory handsheet paper (quantitative 70g / m 2 ), take 0.5g of porous calcium silicate laboratory hand-sheet paper and cut it into a number of paper strips with a length of 100mm and a width of 5mm. ~5mm, use an analytical balance (0.0001g) to weigh the weight of the cylindrical paper sample and the combustion device used to place the cylindrical paper sample, put the cylindrical paper sample into the combustion bracket 3 in the combustion device, and use a butane spray gun to ignite the cylinder After the residue is completely smoldering, it is cooled in the air for 10 seconds and then placed in a desiccator for 2 minutes, then weighed on an analytical balance, and finally the ash value is obtained by calculation, and repeated several times Calculate the average value afterwards. Standard ash and rapid determination of ash are shown in Table 2.

[0052] Table 2

[0053]

Embodiment 3

[0055] Porous calcium silicate laboratory handsheet paper (quantitative 65g / m 2 ), take 0.5g of porous calcium silicate laboratory hand-sheet paper and cut it into a number of paper strips with a length of 200mm and a width of 15mm. ~5mm, use an analytical balance (0.0001g) to weigh the weight of the cylindrical paper sample and the combustion device used to place the cylindrical paper sample, put the cylindrical paper sample into the combustion bracket 3 in the combustion device, and use a butane spray gun to ignite the cylinder After the residue is completely smoldering, it is cooled in the air for 30 seconds and placed in a desiccator for 6 minutes, then weighed on an analytical balance, and finally the ash value is obtained by calculation, and repeated several times Calculate the average value afterwards. Standard ash and rapid determination of ash are shown in Table 3.

[0056] table 3

[0057]

[0058]

[0059] The present invention is carried out according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com