Testing method for hole filling capability of cementing material in hydration process

A technology of gelling materials and testing methods, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as many influencing factors, complex characterization methods, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

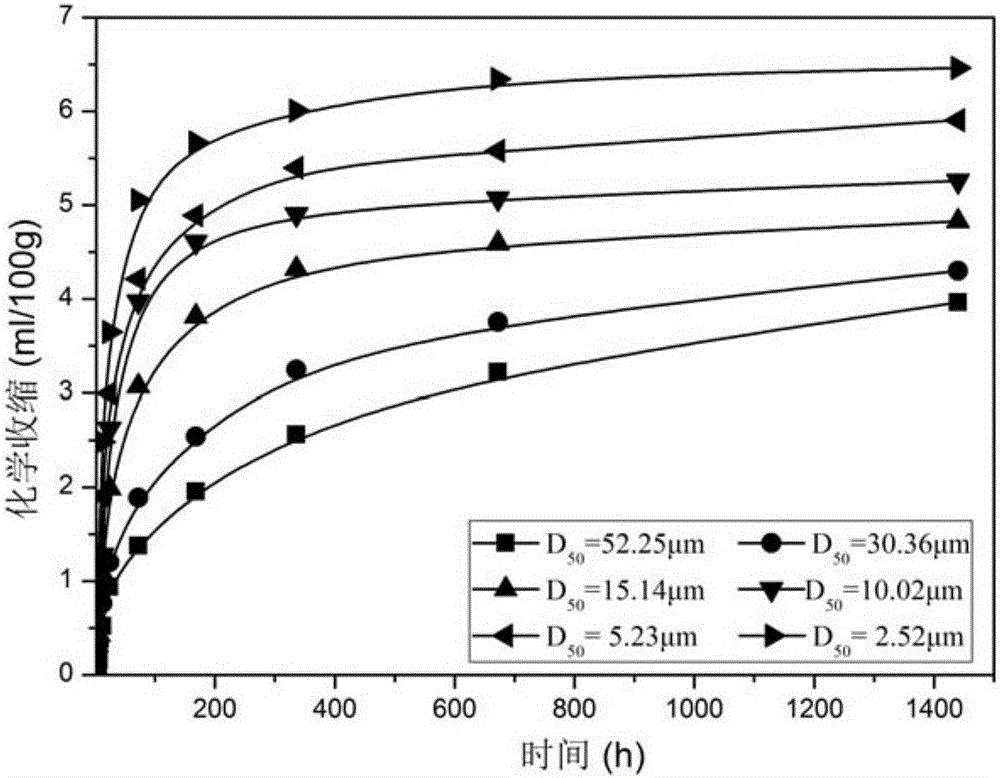

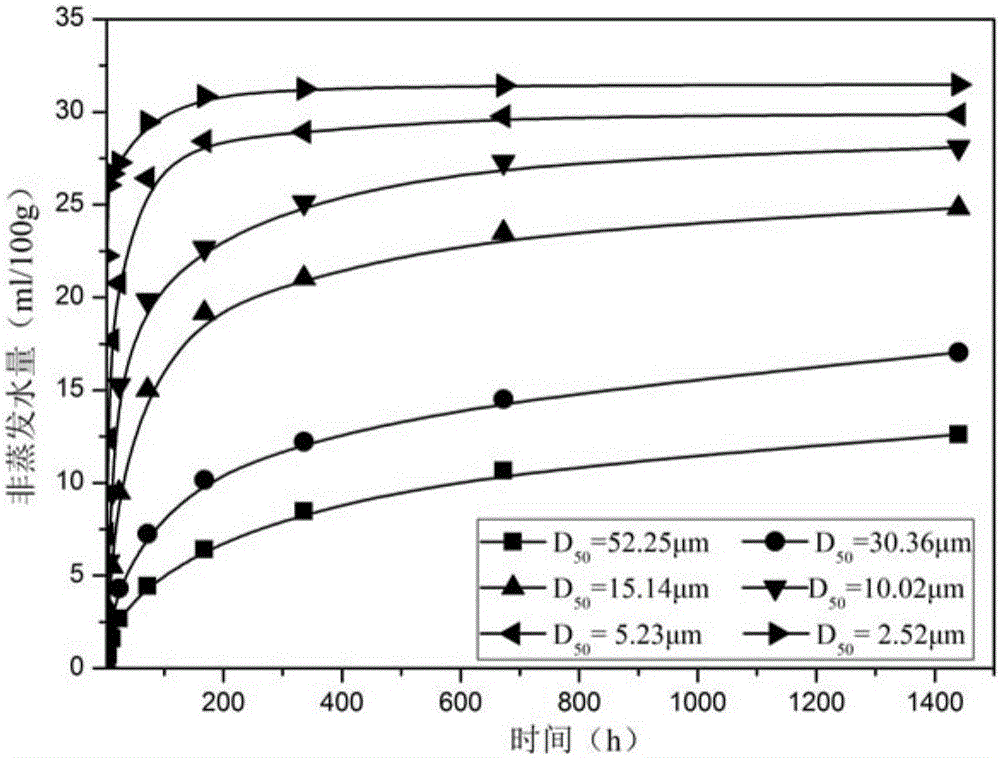

[0043] In this embodiment, Portland cement with different particle size intervals is taken as an example to test the ability to fill pores, including the following steps:

[0044] (1) Test the density ρ of the gelled material c ,Specifically:

[0045] After injecting anhydrous kerosene into the Lishi bottle to the 0-1mL scale line (based on the lower part of the meniscus), cover the bottle stopper and put it in a constant temperature water tank, so that the scale part is immersed in water (the water temperature should be controlled at the scale of the Li's bottle. temperature), keep the temperature for 30 minutes, and record the initial (first) reading. Take out the Lee's bottle from the constant temperature water tank, and carefully wipe off the kerosene-free part of the Lee's bottle's slender neck with filter paper. The cement sample should be passed through a 0.90mm square hole sieve in advance, dried at 110±5°C for 1 hour, and cooled to room temperature in a desiccator. ...

Embodiment 2

[0056] In this embodiment, the slag in different particle size ranges is taken as an example to test the ability to fill pores, including the following steps:

[0057] (1) Test the density ρ of the gelled material c , which is exactly the same as the above method for testing cement density

[0058] (2) According to the method of ASTMC1608, test the chemical shrinkage V during the hydration process of unit volume cementitious material c . The specific test process is exactly the same as that of cement, but in order to promote the hydration of slag, 10% Ca(OH) by mass is added to the powder. 2 Finally, the liquid phase environment uses 0.2mol / L NaOH solution instead of water.

[0059] (3) Test the mass m of the hydrated sample of the gelled material after vacuum drying at 60°C 60 , the mass of the hydrated sample after vacuum drying at 1050°C m 1050 ;

[0060] (4) Calculate the pore filling capacity V of the cementitious material during the hydration process F :

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com