A kind of bar material gradient heat treatment device and heat treatment method

A heat treatment device and rod-shaped material technology, applied in the field of heat treatment, can solve the problems of large temperature gradient measurement error, poor continuity, discrete distribution of temperature measurement points, etc., and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

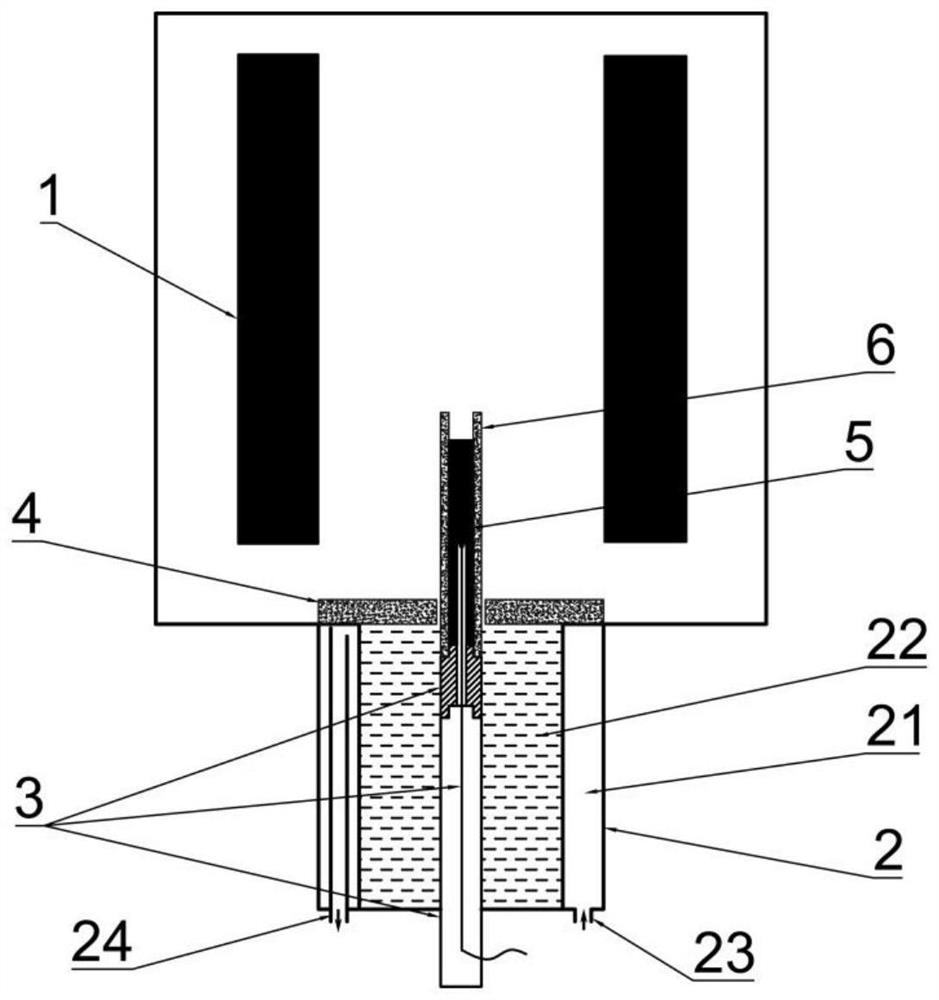

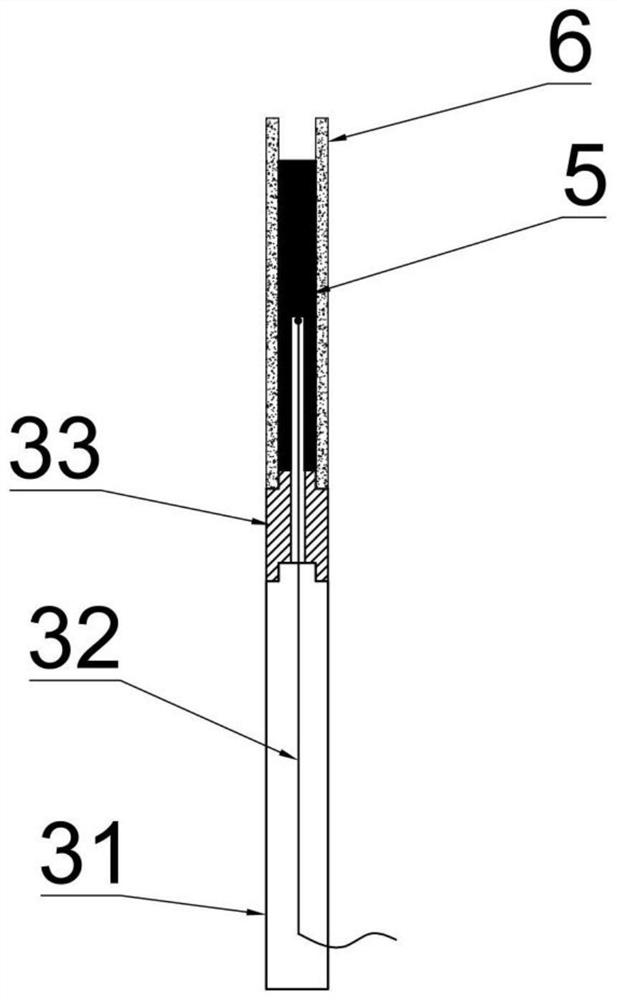

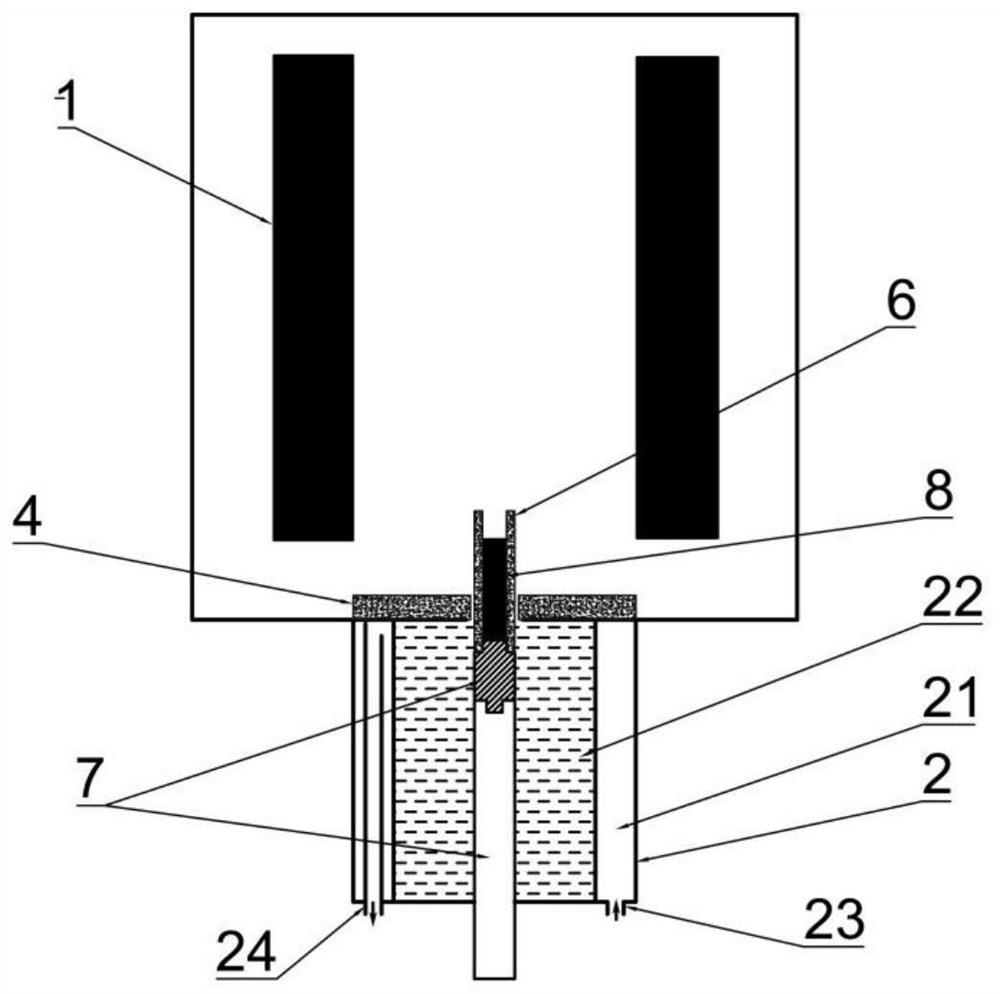

[0039] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0040] The rod material gradient heat treatment device of this embodiment includes a heating device 1, a crystallizer 2, a cooling water channel 21, a coolant 22, a cooling water inlet 23, a cooling water outlet 24, a pulling device and a shielding layer 4; the heating device 1 is Resistance heating is located at the upper end of the crystallizer 2, and a shielding layer 4 is provided between the two to isolate the two. The shielding layer can effectively reduce the influence of heat radiation on the cooling effect of the crystallizer.

[0041] The drawing device is located in the center of the crystallizer 2, and the cavity around the drawing device is provided with a Ga-In-Sn liquid metal coolant 22, which has the advantages of fast heat conduction, good cooling effect, and large temperature gradient of the sample. A double-layer cavity 21, a cooling water inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com