Oil-water alternating wetting corrosion simulation device and method

A simulation device, oil-water technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of high conductivity, high manpower and material resources, difficult testing, etc., to achieve simple and accurate parameter control, experimental The effect of low operating cost and small amount of liquid used in the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

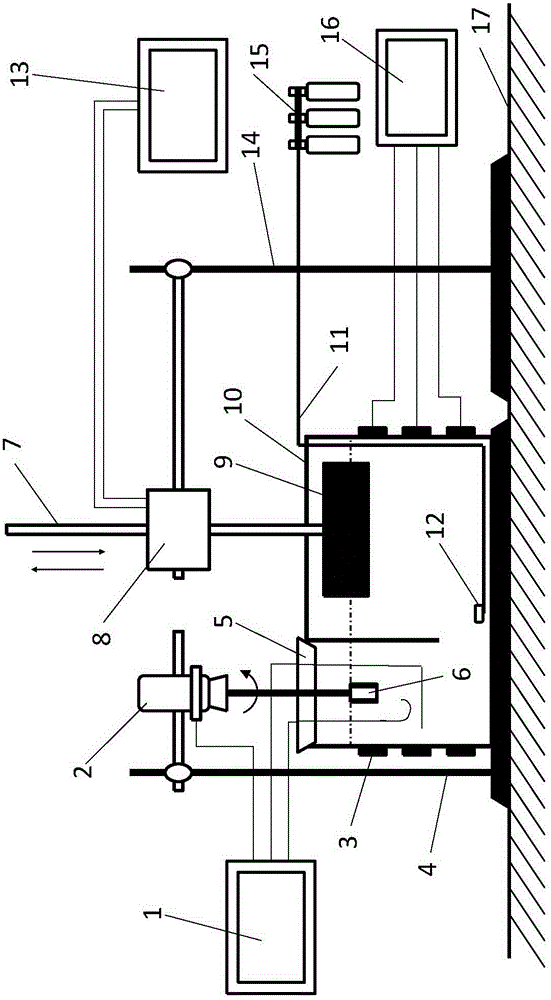

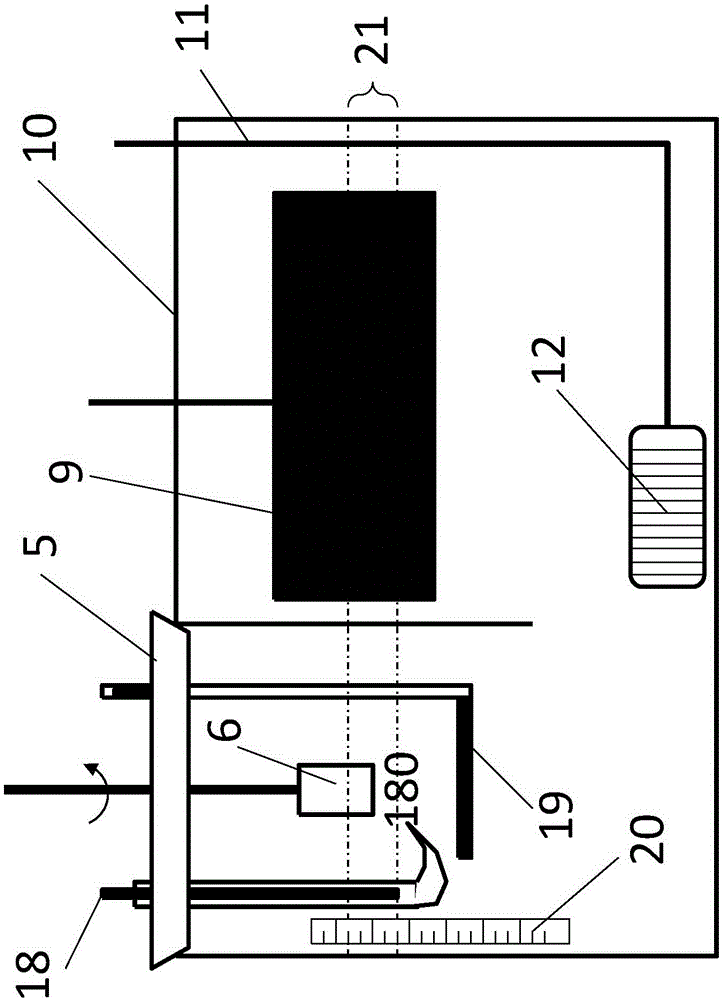

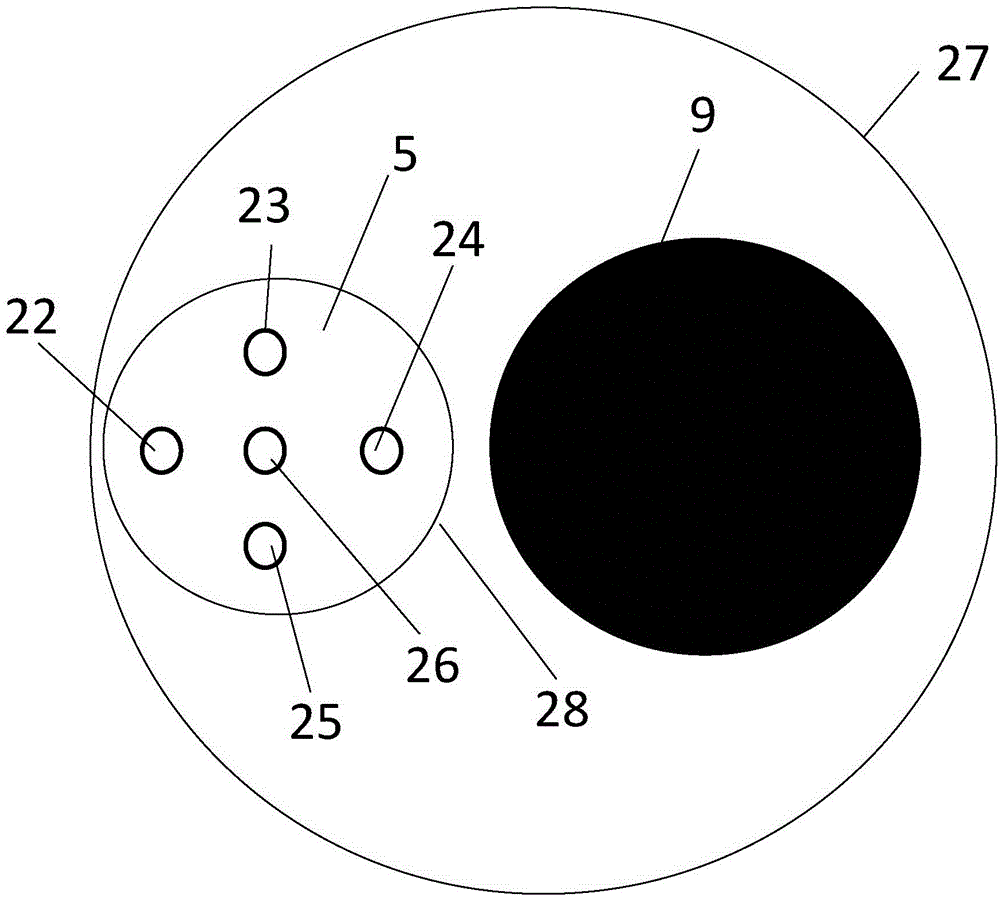

[0052] The oil-water alternate wetting and corrosion simulation device of the present invention comprises an electrochemical signal processing system; a rotating disk electrode system; an oil-water alternate wetting simulation electrolytic cell; an oil-water interface control system; a temperature control system and an aeration system. Specifically, such as figure 1 Shown:

[0053] The electrochemical signal processing system mainly completes the recording, analysis and processing of applied potential control and corrosion current signals, and is mainly realized by an electrochemical workstation 1 capable of recording current signals and supporting software. The three electrode t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com