A kind of preparation method of nanoparticle-doped electrogalvanized layer

A nano-particle and electro-galvanizing technology, which is applied in coatings, electrolytic coatings, etc., can solve the problems of poor corrosion resistance and wear resistance of the galvanized layer, limit the application range of galvanized products, and weak substrate binding force, etc., and achieve improvement The degree of fineness, the effect of saving surface treatment cost and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

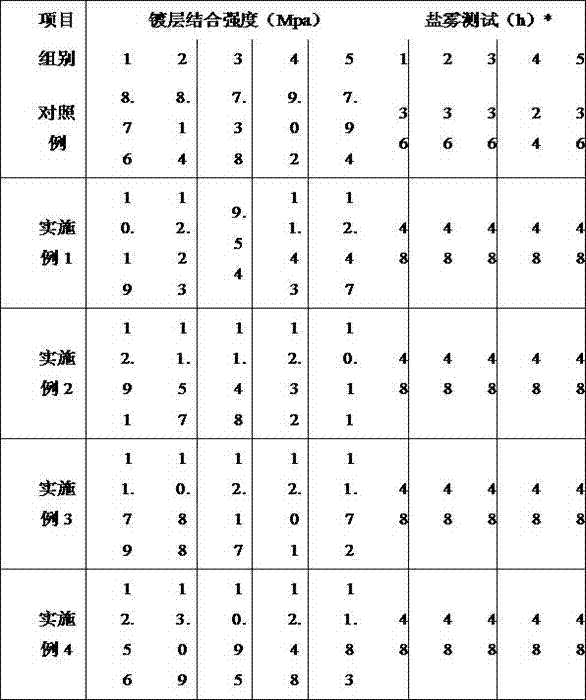

Examples

specific Embodiment 1

[0038] A method for preparing a nanoparticle-doped electro-galvanized layer provided in this embodiment comprises the following steps:

[0039] Step 1. Weigh each component according to the ratio:

[0041] Sodium hydroxide 120 g / L

[0042] ZN-500 brightener 150 ml / L

[0043] ZN-500 low zone walking agent 2 ml / L

[0044] ZN-500 impurity remover 1 ml / L

[0045] ZN-500 water quality treatment agent 1 ml / L

[0046] Nano titanium dioxide particles 1.5 g / L

[0047] Deionized water balance;

[0048] The particle size of the nano-titanium dioxide particles is 20-40 nanometers; the zinc oxide is an industrial first-grade product with a purity of more than 98%; the sodium hydroxide is a solid alkali with a purity of more than 96%.

[0049] Step 2, add deionized water to the plating tank, the amount of deionized water added is 1 / 4 of the total amount of deionized water, then add weighed sodium hydroxide, and stir until the sodium hydroxide is completely ...

specific Embodiment 2

[0056] A method for preparing a nanoparticle-doped electro-galvanized layer provided in this embodiment comprises the following steps:

[0057] Step 1. Weigh each component according to the ratio:

[0058] Zinc oxide 8 g / L

[0059] Sodium hydroxide 80 g / L

[0060] ZN-500 brightener 150 ml / L

[0061] ZN-500 low zone walking agent 1 ml / L

[0062] ZN-500 impurity remover 1 ml / L

[0063] ZN-500 water quality treatment agent 1 ml / L

[0064] Nano titanium dioxide particles 1.0 g / L

[0065] Deionized water balance;

[0066] The particle size of the nano-titanium dioxide particles is 20-40 nanometers; the zinc oxide is an industrial first-grade product with a purity of more than 98%; the sodium hydroxide is a solid alkali with a purity of more than 96%.

[0067] Step 2, add deionized water to the plating tank, the amount of deionized water added is 1 / 4 of the total amount of deionized water, then add weighed sodium hydroxide, and stir until the sodium hydroxide is completely di...

specific Embodiment 3

[0074] A method for preparing a nanoparticle-doped electro-galvanized layer provided in this embodiment comprises the following steps:

[0075] Step 1. Weigh each component according to the ratio:

[0076] Zinc oxide 15 g / L

[0077] Sodium hydroxide 130 g / L

[0078] ZN-500 brightener 150 ml / L

[0079] ZN-500 low zone walking agent 2 ml / L

[0080] ZN-500 impurity remover 1 ml / L

[0081] ZN-500 water quality treatment agent 1 ml / L

[0082] Nano titanium dioxide particles 1.2 g / L

[0083] Deionized water balance;

[0084] The particle size of the nano-titanium dioxide particles is 20-40 nanometers; the zinc oxide is an industrial first-grade product with a purity of more than 98%; the sodium hydroxide is a solid alkali with a purity of more than 96%.

[0085] Step 2, add deionized water to the plating tank, the amount of deionized water added is 1 / 4 of the total amount of deionized water, then add weighed sodium hydroxide, and stir until the sodium hydroxide is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com