38CrMoAl nitrided steel with nitrided layer low in fragility

A technology of nitriding layer and nitriding steel, which is applied in the field of brittle 38CrMoAl nitriding steel with low nitriding layer, which can solve the problems of high brittleness of the nitriding layer, achieve enhanced nitriding performance, increase production and use costs, and reduce stress levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

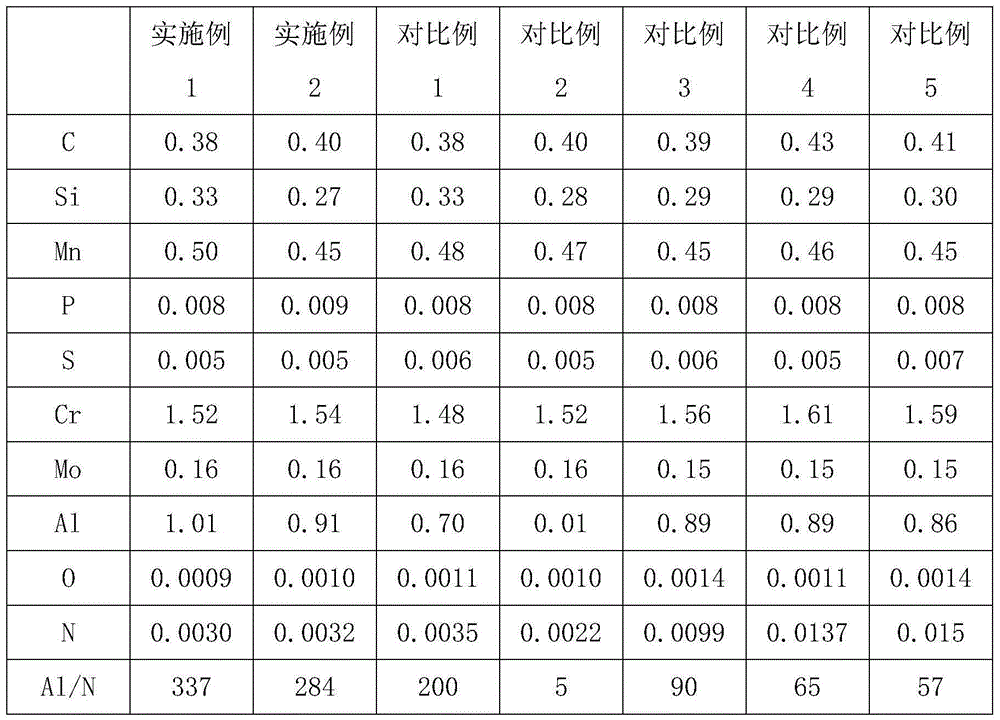

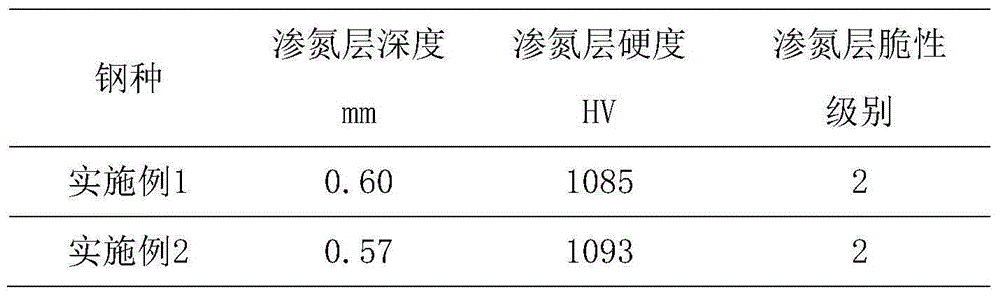

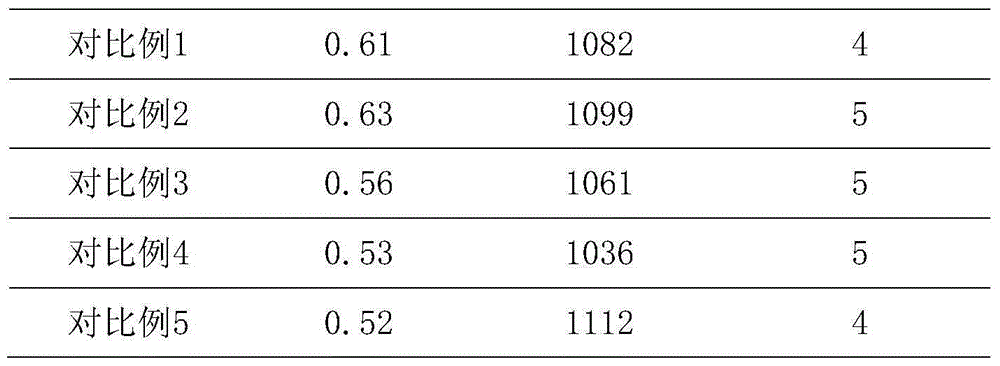

[0027]Prepare the nitriding steel of the present invention and the comparison steel according to the following method: use a 50kg vacuum smelting furnace to smelt a square ingot with a cross section of 125mm×125mm, forge it into a Φ25mm round bar after surface grinding, and carry out normalizing and quenching and tempering treatments on the forged material , intercept the sample block for nitriding treatment. The composition mass percentages of the steel grades obtained from smelting are shown in Table 1. The conventional gas hard nitriding process is adopted. The nitriding process is two-stage nitriding. The first stage is nitriding at 490°C for 30 hours, the ammonia decomposition rate is 15-20%, and the second stage is nitriding at 520°C for 60 hours. The ammonia decomposition rate is 30-40%. The gas hard nitriding process has a long nitriding time and a large depth of the nitriding layer, and the nitriding layer has a higher brittleness tendency, so it is easier to disting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com