Low-temperature-resistant low-compressive deformation seal gasket material for intake manifolds and preparation method thereof

A technology of intake manifold and low pressure change, applied in the field of rubber parts, can solve the problems of high price, poor processability and cold resistance of fluororubber, and achieve the effect of long-term use and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

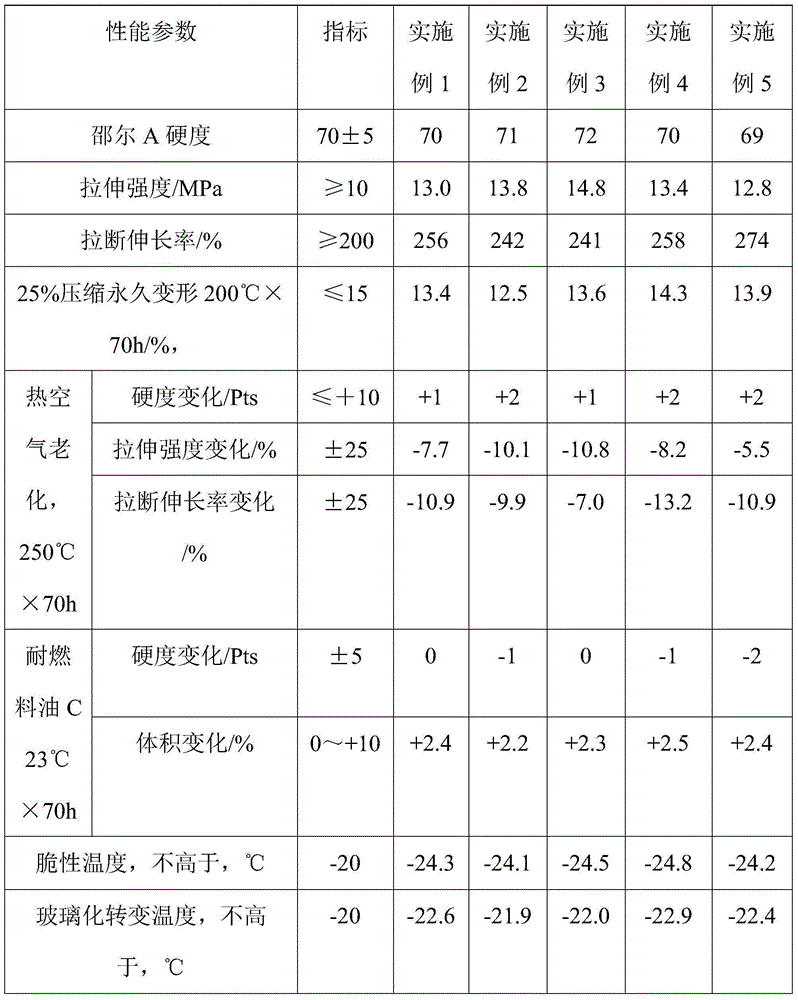

Examples

Embodiment 1

[0029] The present invention proposes a low-temperature-resistant, low-pressure variable intake manifold gasket material, whose raw materials include the following components by weight percentage: 60% of fluororubber raw rubber, 5% of calcium silicate, 16.1% of diatomite, barium sulfate 3%, PTFE micropowder 3%, cerium oxide 5%, calcium hydroxide 2.4%, magnesium oxide 2.8%, lubricant 0.5%, 2,2-bis(4-hydroxyphenyl)hexafluoropropane 1.4%, 0.3% benzyl triphenyl phosphorus chloride, 0.5% auxiliary materials.

[0030] A kind of preparation method of low-temperature resistant, low-pressure variable intake manifold gasket material proposed by the present invention comprises the following steps:

[0031] S1. Prepare materials according to the proportion and send all raw materials into the internal mixer for primary mixing. After 16 hours at room temperature, carry out secondary mixing to obtain a hardness of 70 degrees, a tensile strength of 12.7MPa, and an elongation at break. 258% s...

Embodiment 2

[0035] A low-temperature-resistant, low-pressure variable intake manifold sealing gasket material proposed by the present invention, its raw materials include the following components by weight percentage: 64.1% of fluororubber raw rubber, 5% of calcium silicate, 5% of diatomaceous earth, barium sulfate 4%, PTFE micropowder 10%, cerium oxide 2%, calcium hydroxide 4.5%, magnesium oxide 1.5%, lubricant 2%, 2,2-bis(4-hydroxyphenyl)hexafluoropropane 0.6%, 0.7% benzyl triphenylphosphorous chloride, 0.6% auxiliary materials.

[0036] A kind of preparation method of low-temperature resistant, low-pressure variable intake manifold gasket material proposed by the present invention comprises the following steps:

[0037] S1. Prepare materials according to the proportion and send all raw materials into the internal mixer for primary mixing, and then carry out secondary mixing after parking at room temperature for 18 hours. The obtained hardness is 72 degrees, tensile strength is 14.6MPa,...

Embodiment 3

[0041] The present invention proposes a low-temperature-resistant, low-pressure variable intake manifold sealing gasket material, whose raw materials include the following components by weight percentage: 62% of fluororubber raw rubber, 7% of calcium silicate, 10% of diatomite, barium sulfate 6%, PTFE micropowder 4.2%, cerium oxide 3.2%, calcium hydroxide 3%, magnesium oxide 1.5%, lubricant 0.8%, 2,2-bis(4-hydroxyphenyl)hexafluoropropane 0.9%, 0.4% benzyltriphenylphosphorus chloride, 1% auxiliary material; wherein, the diatomite is surface-modified diatomite; the modifier used for surface-modified diatomite is methacryloyloxysilane , stearic acid, silane coupling agent KH-550, silane coupling agent KH-560, silane coupling agent KH-580, silane coupling agent ND-42 in a weight ratio of 1:3:2:4:2: 1 combination.

[0042] A kind of preparation method of low-temperature resistant, low-pressure variable intake manifold gasket material proposed by the present invention comprises the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com