Hyperbranched polyurethane containing epoxy groups as well as preparation method and application thereof

A technology of hyperbranched polyurethane and epoxy group is applied in the field of hyperbranched polyurethane to achieve the effects of high yield and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

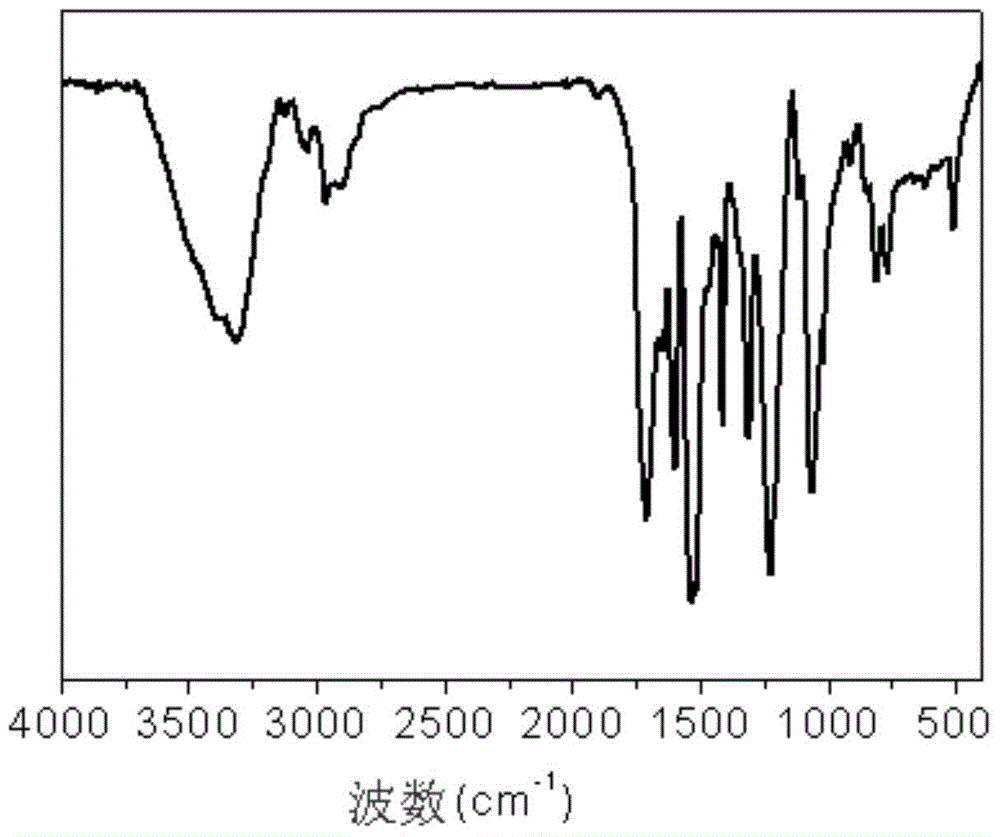

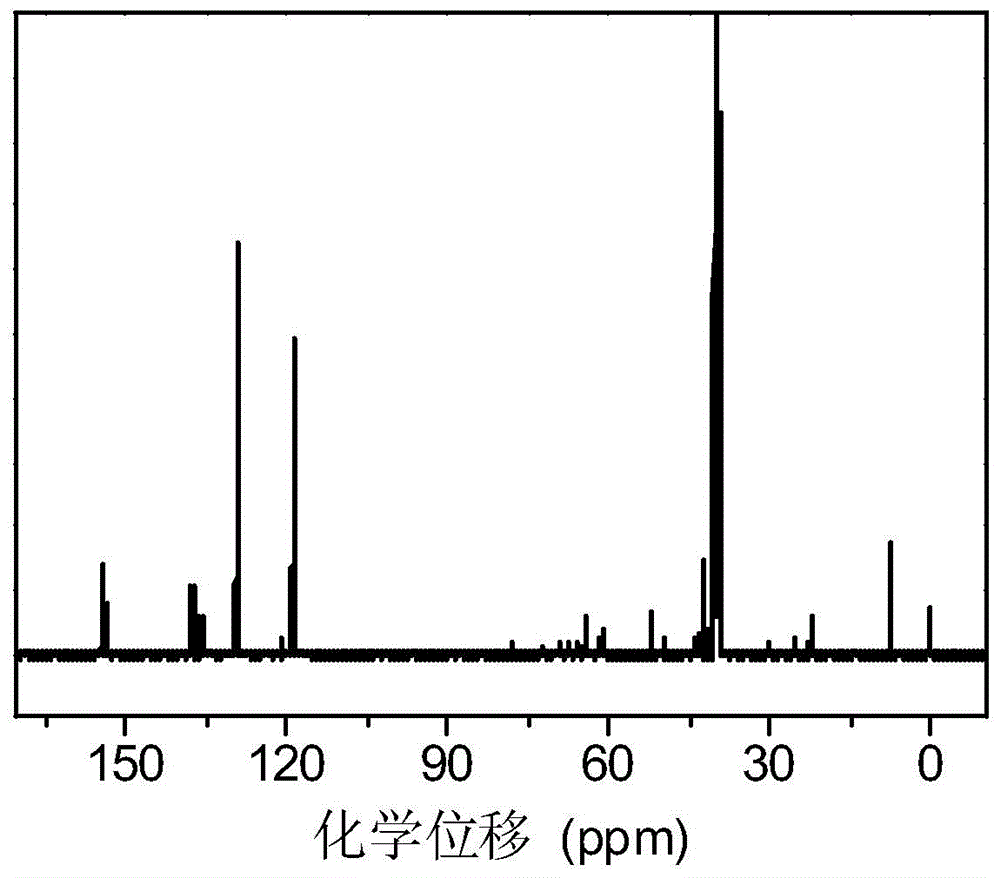

Image

Examples

Embodiment 1

[0047] The preparation method of the hyperbranched polyurethane containing epoxy group of the present invention may further comprise the steps:

[0048] 1) Dissolve 4,4'-diphenylmethane diisocyanate and trimethylolpropane in tetrahydrofuran respectively to obtain a diisocyanate solution and a trihydric alcohol solution, wherein 4,4'-diphenyl The molar ratio of the isocyanate in methane diisocyanate to the hydroxyl group in trimethylolpropane in the trihydric alcohol solution is 1:1, and the mass concentration of the diisocyanate solution and the mass concentration of the trihydric alcohol solution are both 20%;

[0049] 2) Under a nitrogen atmosphere at 60°C, add the diisocyanate solution into the trihydric alcohol solution for reaction, wherein the reaction temperature is 60°C, and the reaction time is 24h;

[0050]3) In the detection step 2), after the reaction of the diisocyanate solution and the trihydric alcohol solution is completed, the content of the hydroxyl group in ...

Embodiment 2

[0055] The preparation method of the hyperbranched polyurethane containing epoxy group of the present invention may further comprise the steps:

[0056] 1) Dissolve 4,4'-diphenylmethane diisocyanate and trimethylolpropane in tetrahydrofuran respectively to obtain a diisocyanate solution and a trihydric alcohol solution, wherein 4,4'-diphenyl The molar ratio of the isocyanate in the methane diisocyanate and the hydroxyl group in the trimethylolpropane in the trihydric alcohol solution is 5:4, and the mass concentration of the diisocyanate solution and the mass concentration of the trihydric alcohol solution are 17%;

[0057] 2) Under a nitrogen atmosphere at 60°C, add the diisocyanate solution into the trihydric alcohol solution for reaction, wherein the reaction temperature is 60°C, and the reaction time is 24h;

[0058] 3) Detect the content of isocyanate in the reaction system after the reaction between diisocyanate solution and trihydric alcohol solution in step 2), and the...

Embodiment 3

[0063] The preparation method of the hyperbranched polyurethane containing epoxy group of the present invention may further comprise the steps:

[0064] 1) Dissolve hexamethylene diisocyanate and glycerol in N,N-dimethylacetamide respectively to obtain a diisocyanate solution and a trihydric alcohol solution, wherein the hexamethylene diisocyanate in the diisocyanate solution The molar ratio of the isocyanate and the hydroxyl group in glycerol in the trihydric alcohol solution is 1:2, and the mass concentration of the diisocyanate solution and the trihydric alcohol solution are both 30%;

[0065] 2) Under a nitrogen atmosphere at 80°C, add the diisocyanate solution into the trihydric alcohol solution for reaction, wherein the reaction temperature is 80°C, and the reaction time is 15 hours;

[0066] 3) After the reaction of the diisocyanate solution and the trihydric alcohol solution in the detection step 2) is completed, the content of the hydroxyl group in the reaction system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com