Method of taking microalgae as raw material to prepare 5-hydroxymethyl furfural

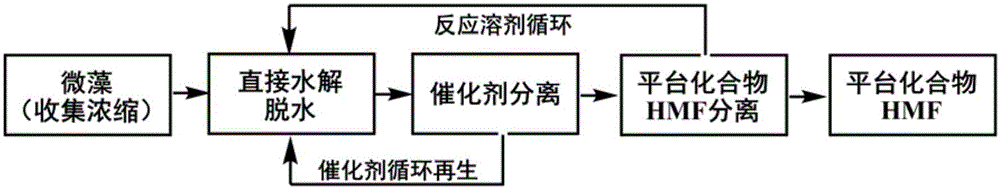

A technology of hydroxymethylfurfural and microalgae, applied in the direction of organic chemistry, can solve the problems of difficult separation, recycling and reuse of inorganic acids, high cost of preparation of ionic liquids, low cost and greenness, etc., to achieve easy cultivation, solidification The effect of high carbon efficiency and easy localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

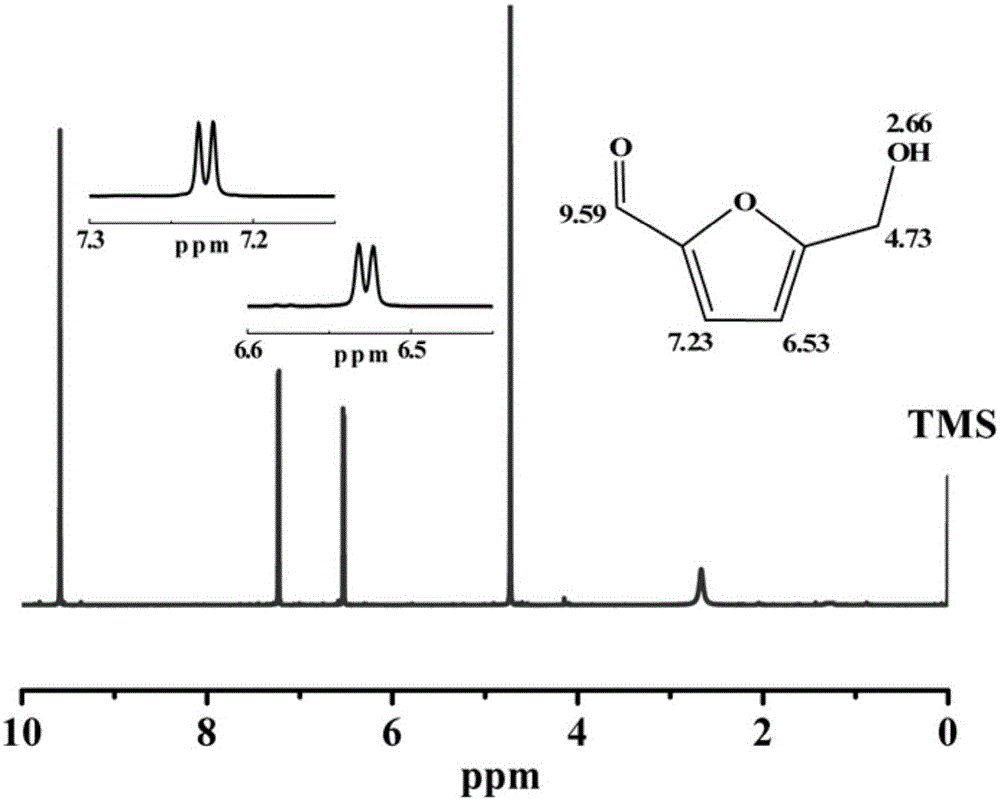

Embodiment 1

[0034] The experiments were carried out in a Parr autoclave with a volume of 100 ml. First add 0.5g Scenedesmus and 50mL deionized water in the reaction kettle, the solid-to-liquid ratio is 1g:100mL, wherein, the carbohydrate content of Scenedesmus is 65.00% (mass percentage), and the N content is 0.5% (mass percentage), The S content is 0% (mass percentage). After adding 0.2g of SAPO-34 catalyst, the reactor was sealed, and high-purity nitrogen was introduced to replace the air in the reactor, and the initial relative partial pressure of nitrogen was set to 1MPa, and the stirring speed was controlled at 600r / min. After the heating started, the temperature rose to 160°C at a rate of 15K / min, and the reaction lasted for 480min, then the heating was stopped and cooled to room temperature. After the reaction solution was centrifuged, the solid residue was dried overnight in an oven at 100° C., and the centrifuged supernatant was passed through a 0.22 μm microfilter for HPLC quan...

Embodiment 2

[0039] The specific implementation process is the same as in Example 1, except that the raw material added is chlorella, the carbohydrate content of chlorella is 50.24wt%, the N content is 0.3wt%, and the S content is 0.2wt%. Add 2.5g of Chlorella and 50mL of reaction solvent (composed of water and methyl isobutyl ketone, the volume ratio is 4:6), the solid-to-liquid ratio is 5g:100mL, and 2g of HZSM-5 catalyst is added at the same time; the reaction temperature is stabilized at 180°C , the reaction time was shortened to 360min, and the initial partial pressure of nitrogen was set at 1.4MPa. After the reaction is finished, the hydrothermal conversion rate of the chlorella reaches 75.3%, and the HMF yield reaches 26.7%.

Embodiment 3

[0041] The specific implementation process is the same as in Example 1, except that the added raw material is salina, the carbohydrate content of salina is 40.00wt%, the N content is 0.18wt%, and the S content is 0.35wt%. The quality of the salt algae added is 5g, the reaction solvent is 50mL (composed of water and toluene, the volume ratio is 3:7), the solid-liquid ratio is 10g:100mL, and the mass of 3g of Hβ catalyst is added at the same time, the temperature of the system is raised to 200 ° C, and the reaction time The time was shortened to 240min, and the initial partial pressure of nitrogen was set at 1.6MPa. After the reaction is finished, the hydrothermal conversion rate of the salina reaches 92.8%, and the HMF yield reaches 38.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com