Ultrafine lanthanum oxide and preparation method thereof

A technology of lanthanum oxide and lanthanum salt, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems that large particles cannot meet the requirements, and achieve the prevention of re-agglomeration, short standing time, and prevention of particle size change big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

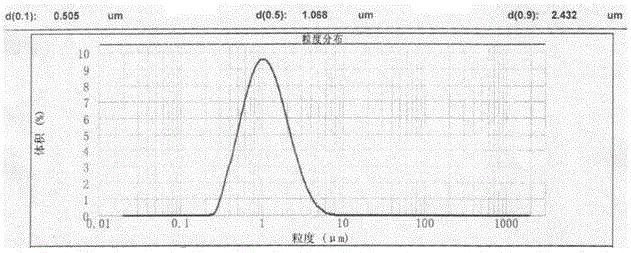

[0030] The lanthanum chloride solution is obtained from the rare earth ore separated by the extraction tank, and adjusted to a concentration of 1.0mol / l, pH:1. Take 2g of sodium dodecylbenzenesulfonate as an anionic surfactant and add it to pure water at 50°C, and keep stirring until the sodium dodecylbenzenesulfonate is completely dissolved to obtain an aqueous solution containing sodium dodecylbenzenesulfonate Get lanthanum chloride solution 614ml, add above-mentioned aqueous solution in the lanthanum chloride solution, and stir. Take 200 g of oxalic acid and dilute to obtain 3.17 L of oxalic acid solution with a solution concentration of 0.5 mol / L. While the oxalic acid solution is constantly stirring, quickly add the lanthanum chloride solution containing sodium dodecylbenzenesulfonate, stir and age for 1.5 hours, then suction filter and wash until the pH value of the washing solution is 7, and remove the precipitate Dry at 120°C for 1 hour, then burn at 1000°C, the heati...

Embodiment 2

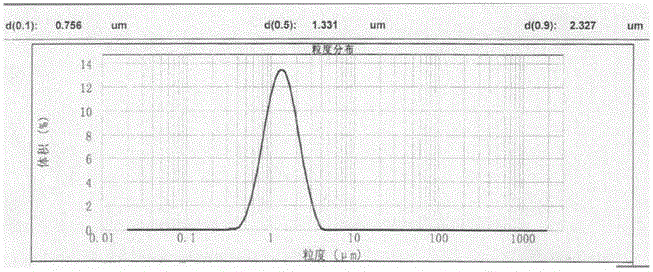

[0032] Dissolve lanthanum carbonate in nitric acid to obtain lanthanum nitrate solution, adjust to a concentration of 0.8mol / l, pH: 1.5. Take 2.3g of sodium dodecylbenzenesulfonate as an anionic surfactant and add it to pure water at 65°C and keep stirring until the sodium dodecylbenzenesulfonate is completely dissolved to obtain an aqueous solution containing sodium dodecylbenzenesulfonate Get lanthanum nitrate solution 1150ml, add above-mentioned aqueous solution in the lanthanum chloride solution, and stir. Take 270 g of oxalic acid and dilute to obtain 3.57 L of oxalic acid solution with a concentration of 0.6 mol / L. While the oxalic acid solution is constantly stirring, quickly add the lanthanum nitrate solution containing sodium dodecylbenzenesulfonate, stir and age for 1 hour, then carry out suction filtration and washing until the pH of the washing solution is 7, and put the precipitate in Dry at 90°C, and then burn at 900°C. During burning, the heating time is 4 hour...

Embodiment 3

[0034] Dissolve lanthanum oxide in 18.6mol / L concentrated sulfuric acid to obtain lanthanum sulfate solution, adjust to 0.5mol / L, pH:1. Take 1g of sodium lauryl sulfate and stir it as an anionic surfactant, add it into pure water at 80°C, and keep stirring until the sodium lauryl sulfate is completely dissolved to obtain an aqueous solution containing sodium lauryl sulfate; take lanthanum sulfate solution 1230ml, the above aqueous solution was added to the lanthanum sulfate solution, and stirred. Take 150g of oxalic acid and dilute to obtain 1488ml of solution. When the oxalic acid solution is continuously stirred, quickly add it to the lanthanum sulfate solution containing sodium lauryl sulfate, and stir and age for 0.5 hours, filter and wash to pH: 7, and dry the precipitate at 100°C Dry for 2 hours, then burn at 800°C. During burning, the heating time is 3.5 hours, and the holding time is 2 hours. After burning, grind and sieve to obtain ultrafine lanthanum oxide. The D50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com