Controllable-interlamellar-spacing stable graphene oxide film and preparation method thereof

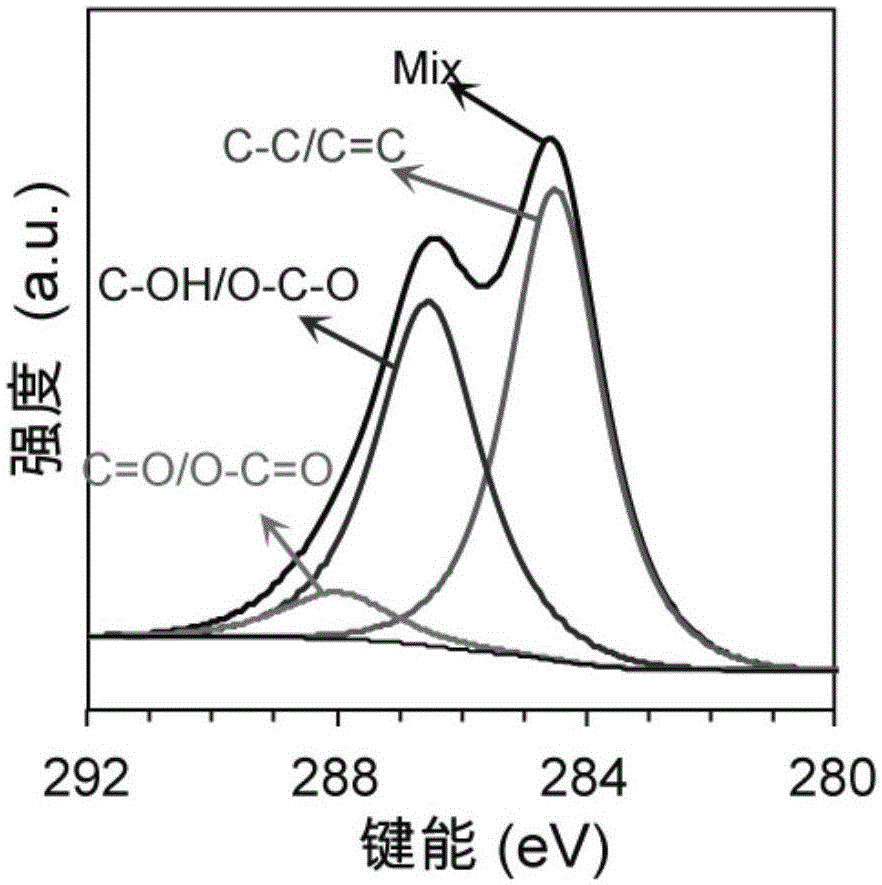

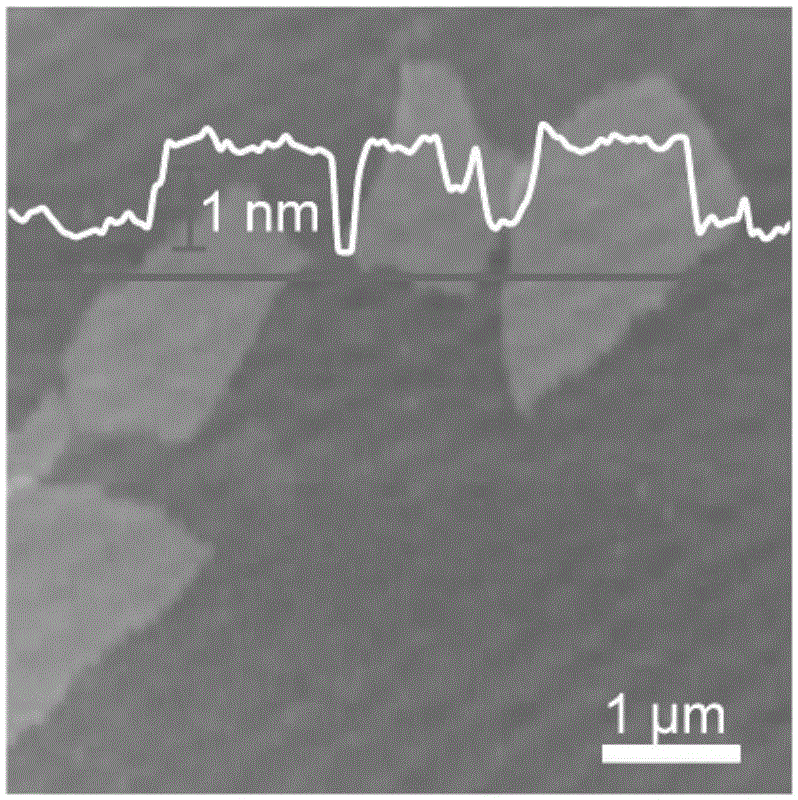

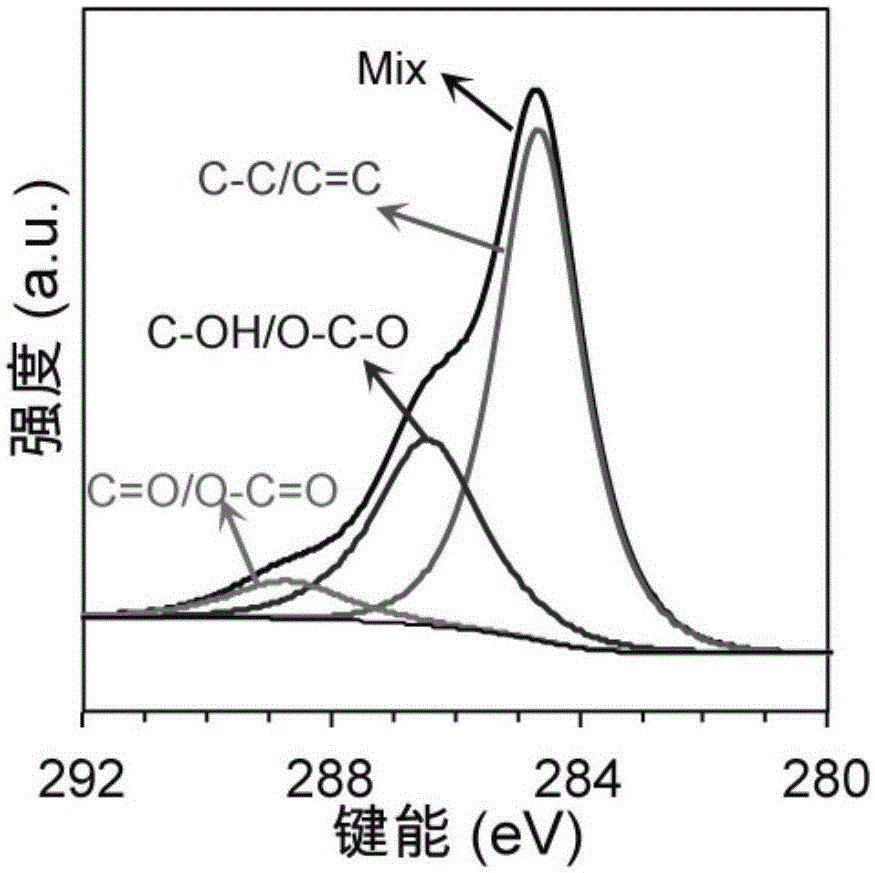

A graphene film and graphene technology are applied in the field of stable graphene oxide film and its preparation, which can solve the problems of graphene oxide stacked lamella structure damage, poor selectivity of graphene oxide film and the like, and achieve high stability, Reduced layer spacing, reduced hydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the preparation method of a stable graphene oxide film with controllable layer spacing is as follows:

[0047] (1) Prepare graphene oxide by improving the hummer method

[0048] ①Put 3g of graphite flakes, 12mL of concentrated sulfuric acid, 2.5g of potassium persulfate, and 2.5g of phosphorus pentoxide into a single-necked flask, react at 80°C for 4.5h under stirring conditions, cool the resulting reaction solution to room temperature, and add 500mL Deionized water, stirred overnight, then filtered, rinsed the filter cake with 1500mL deionized water, and aired at room temperature for 24 hours to remove the moisture in the filter cake, which completed the pretreatment of graphite;

[0049] ②Put 120mL of concentrated sulfuric acid at 0°C into the conical flask, then add the graphite pretreated in step ①, and then add 15g of potassium permanganate, and control the addition speed of potassium permanganate as slow as possible so that the conical flask T...

Embodiment 2

[0060] In the present embodiment, the preparation method of the highly stable graphene oxide film with controllable interlayer distance is basically the same as the operation of embodiment 1, the only difference is that in step (3), the graphene oxide aqueous solution obtained in step (1) is taken 100 mL was mixed with 100 mL of the partially reduced graphene oxide aqueous solution obtained in step (2), and treated with 100 W ultrasonic for 0.5 h to form a casting solution. The interlayer spacing of the graphene oxide film prepared in this example is 0.84 nm.

Embodiment 3

[0062] In the present embodiment, the preparation method of the stable graphene oxide film with controllable interlayer spacing is basically the same as the operation of embodiment 1, the only difference is: in step (3), take 40 mL of the graphene oxide aqueous solution obtained in step (1) and 160 mL of the partially reduced graphene oxide aqueous solution obtained in step (2) was mixed, and treated with 100 W ultrasonic for 0.5 h to form a casting solution. The interlayer spacing of the graphene oxide film prepared in this example is 0.80 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com