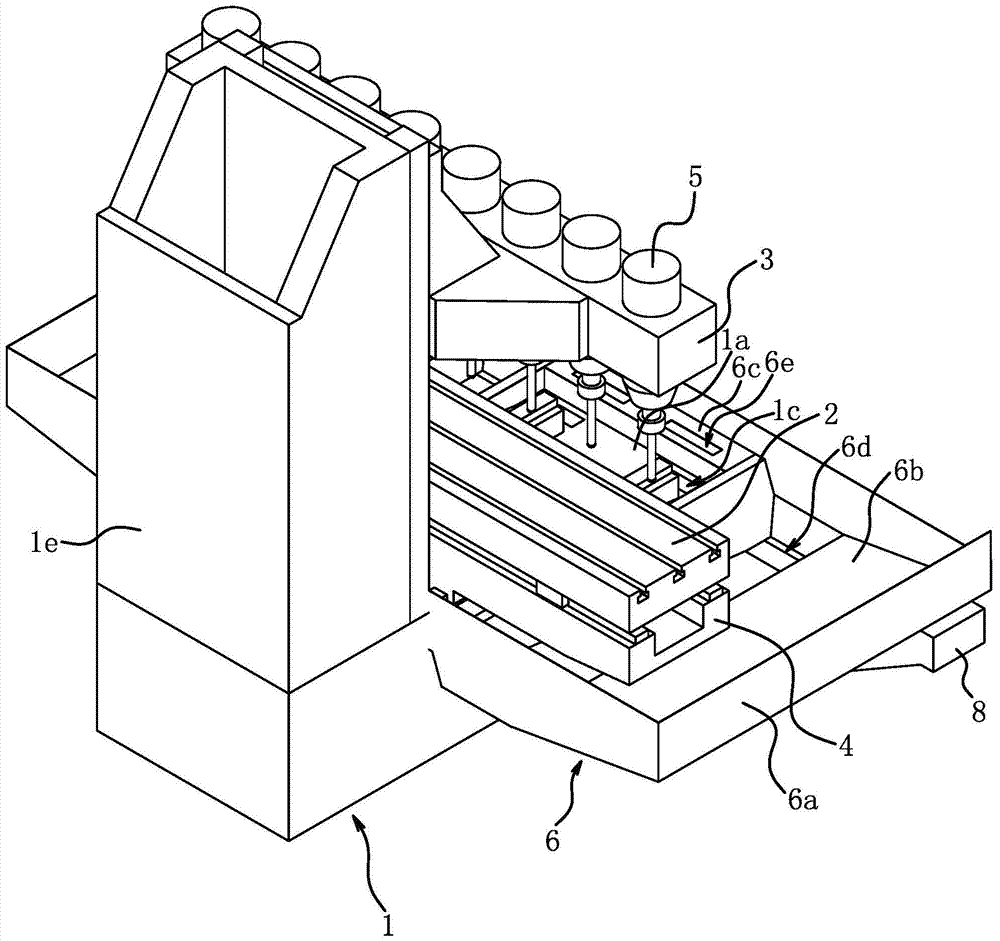

Multi-station vertical engraving and milling machine

A multi-station, engraving and milling machine technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve the problems of large horizontal span, reduce equipment market competitiveness, increase production and transportation costs, etc., to avoid The effect of excess weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

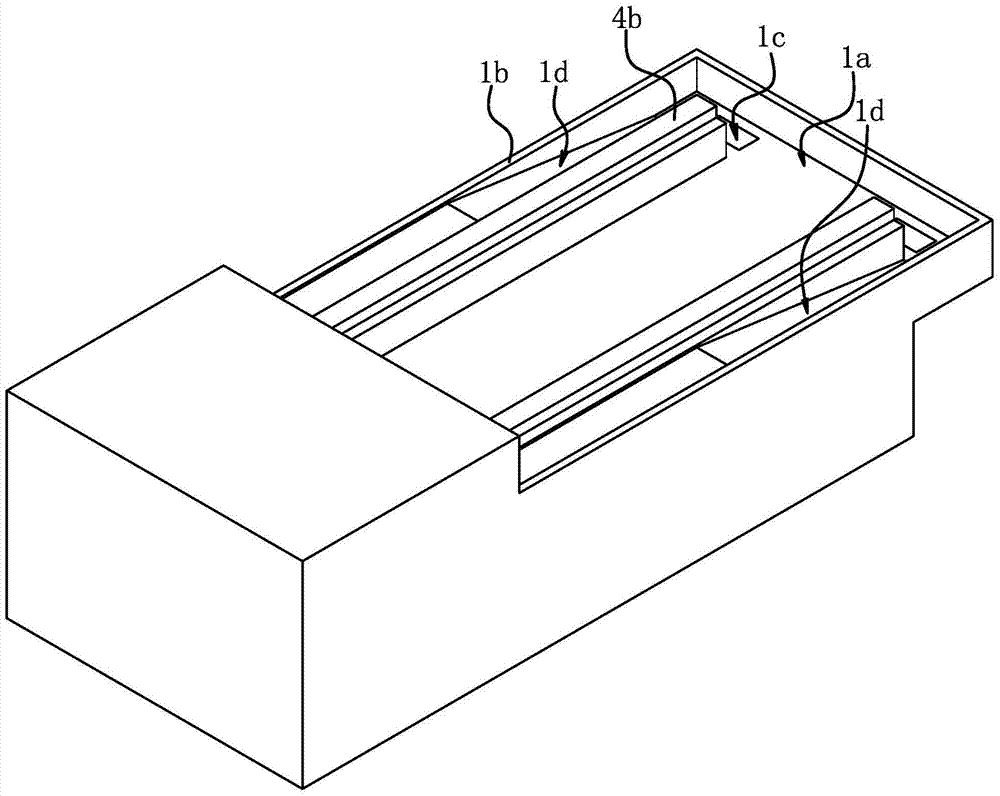

Method used

Image

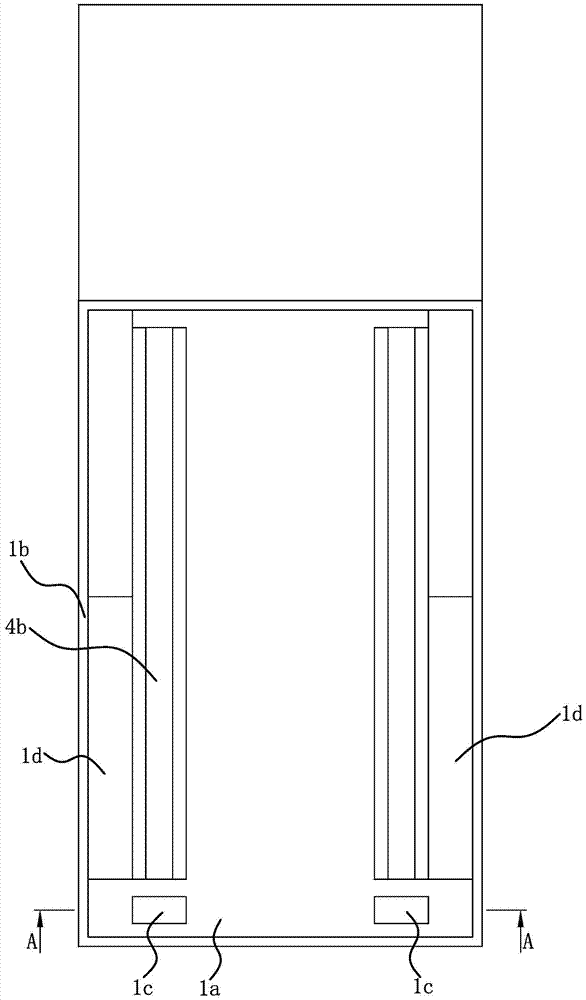

Examples

Embodiment 2

[0032] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 5 As shown, the number of chip dropping holes 1c is eight, the cross section of the chip dropping holes 1c is trapezoidal, and the cross section of the spacer 1f between the two chip dropping holes 1c is triangular in shape, and the cutting chips in this area fall naturally, further facilitating the base 1 Cleaning of cutting chips.

Embodiment 3

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 6 As shown, there are eight chip holes 1c, and the top of the cross section of the spacer 1f between the two chip holes 1c is arc-shaped, so that the cutting chips in this area fall naturally, which further facilitates the cleaning of the cutting chips on the base 1 .

Embodiment 4

[0036]The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 12 The chip conveying device shown is a screw conveyor 9 , and the chip drop hole 1 c , the chip drop hole 1 c and the auxiliary chip drop hole 6 e of the two chip guide buckets 6 b are all in communication with the pipe sleeve of the screw conveyor 9 . The use of the screw conveyor 9 to convey cutting chips can significantly reduce the noise outside the multi-station vertical engraving and milling machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com