Laser sealing welding process of 3a21 aluminum alloy shell

An aluminum alloy shell, 3A21 technology, applied in the field of micro-assembly component packaging and testing technology, can solve the problems of complex 4047 aluminum alloy production process, affecting product yield and reliability, complex circuit and bare chip structure, etc. The appearance of the weld is beautiful and the thermal deformation is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

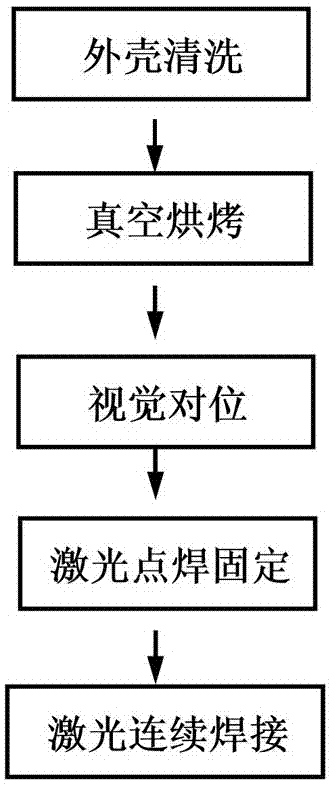

[0029] In this embodiment, the 3A21 aluminum alloy shell to be laser sealed and welded is 30 mm × 30 mm, and the inner cavity volume is about 3.7 cm 3 , the 3A21 aluminum alloy shell includes a 3A21 aluminum alloy shell and a 3A21 aluminum alloy cover plate, the welded joints are butt jointed, the thickness of the cover plate is 1mm, and the fit gap between the shell and the cover plate is 0.06mm. A laser sealing welding process of the above-mentioned 3A21 aluminum alloy casing of the present invention, such as figure 1 shown, including the following steps:

[0030] (1) Cleaning: Soak the 3A21 aluminum alloy casing with acetone and absolute ethanol in sequence. After soaking, wipe the inside and outside of the 3A21 aluminum alloy casing with dust-free paper to remove oil stains on the surface of the casing, and then dry the casing with nitrogen.

[0031] (2) Vacuum baking: place the cleaned 3A21 aluminum alloy shell on the heating plate in a vacuum oven, and bake the shell fo...

Embodiment 2

[0038] In this embodiment, the 3A21 aluminum alloy shell to be sealed and welded by laser is 30mm×30mm, and the inner cavity volume is about 3.4cm 3 , the 3A21 aluminum alloy shell includes a 3A21 aluminum alloy shell and a 3A21 aluminum alloy cover plate, the welded joints are butt jointed, the thickness of the cover plate is 1.5mm, and the fit gap between the shell and the cover plate is 0.1mm. A laser sealing welding process of the above-mentioned 3A21 aluminum alloy casing of the present invention, such as figure 1 shown, including the following steps:

[0039] (1) Cleaning: Soak the 3A21 aluminum alloy casing with acetone and absolute ethanol in sequence. After soaking, wipe the inside and outside of the 3A21 aluminum alloy casing with dust-free paper to remove oil stains on the surface of the casing, and then dry the casing with nitrogen.

[0040] (2) Vacuum baking: place the cleaned 3A21 aluminum alloy shell on the heating plate in a vacuum oven, bake the shell for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com