An electric arc machining discharge state detection system

An arc processing and discharge state technology, applied in arc welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as large fluctuation range, large adjustable range, and inappropriate detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

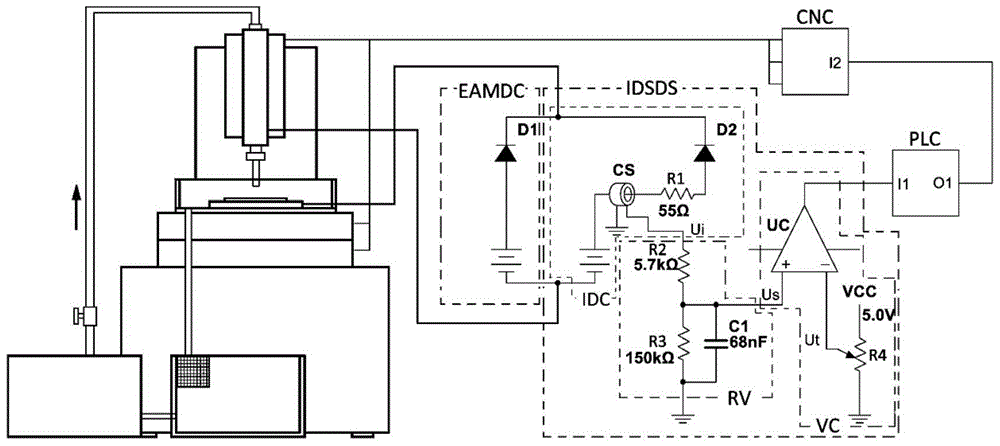

[0012] established as figure 1 The circuit diagram of the arc machining discharge state detection system shown mainly includes an arc machining machine tool system, an independent detection circuit IDC, a voltage stabilizing circuit RV, a voltage comparison circuit VC, a PLC module and a numerical control system CNC.

[0013] The discharge state in the arc machining process is mainly divided into short circuit, open circuit and normal processing. Such as figure 1 As shown, the rated voltage of the arc power supply V1 is 80V, which is applied to both ends of the electrode and the workpiece for arc processing. The rated voltage of the DC power supply V2 in the independent detection circuit IDC is 55V, and the resistance value of the fixed value resistor R1 is 55Ω. Diodes D1 and D2 isolate V1 from the independent detection circuit IDC, increasing the reliability of the detection results. When the arc processing is in an open circuit state, there is no current in the detection ...

Embodiment 2

[0018] The rated voltage of the DC power supply V2 in the independent detection circuit IDC is 65V, the resistance value of the fixed-value resistor R1 is 65Ω, and the others are the same as in the first embodiment.

Embodiment 3

[0020] The rated voltage of the DC power supply VCC in the voltage comparison circuit VC is 10V, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com