Conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and preparation method therefor

A conductive carbon felt and gas diffusion technology, applied in chemical instruments and methods, separation methods, greenhouse gas capture, etc., can solve the problems of restricting industrial production and practical application, low photocatalytic activity, small specific surface area, etc., and achieve easy The effect of industrial production, high gas diffusion performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

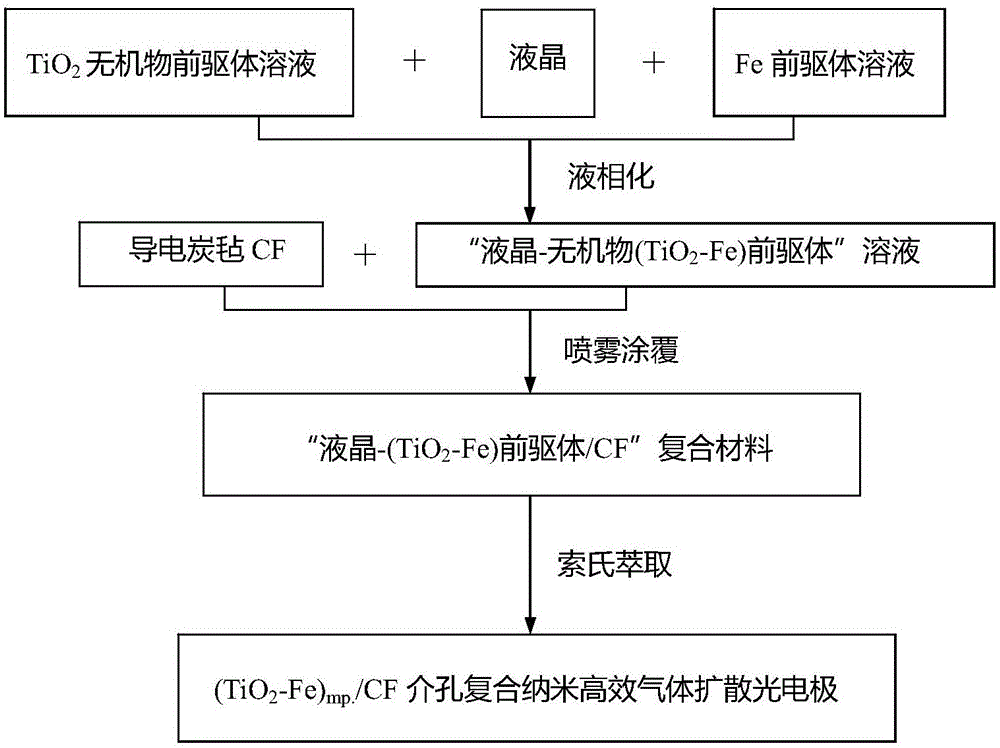

[0042] The preparation process of the present invention comprises:

[0043] 1) Using titanium tetrachloride as the starting material, using the liquid crystal of the surfactant "sodium perfluorooctanoate" as the soft template, under the action of liquid phase, synthesize the "liquid crystal-inorganic precursor" solution. The hydrochloric acid solution of titanium tetrachloride and ferric nitrate is first added into the three-necked flask together, and the liquid crystal is added through the funnel, and the dropping rate is generally controlled at 0.1–0.5ml·min -1 between; synthesis of "liquid crystal-inorganic precursor" solution;

[0044] 2) Put the "liquid crystal-inorganic precursor" solution into the spray device, the optimal distance between the spray nozzle and the conductive carbon felt is 40cm-50cm, air atomization nozzle, flow rate 0.01-0.05ml / min, pressure 2-10Mpa , temperature 20–30°C, relative humidity 80–90%;

[0045] 3) Add "TiO 2 –Fe-Liquid Crystal” / CF is pla...

Embodiment 1

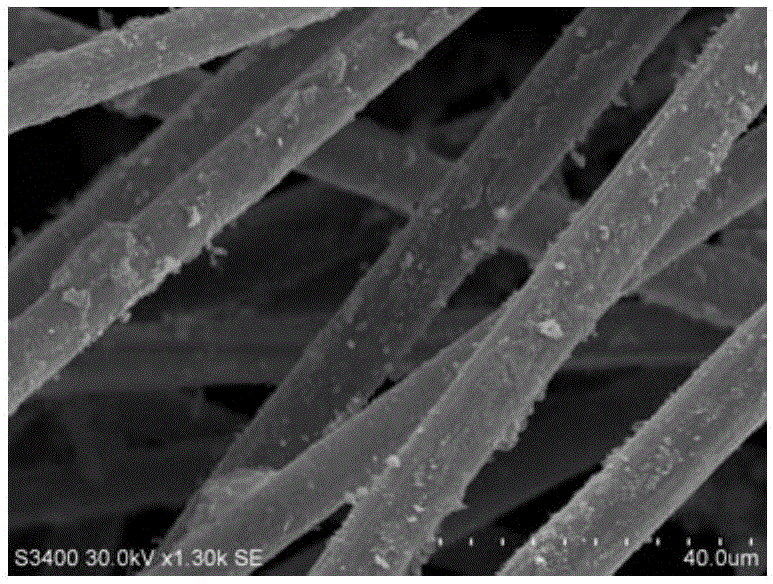

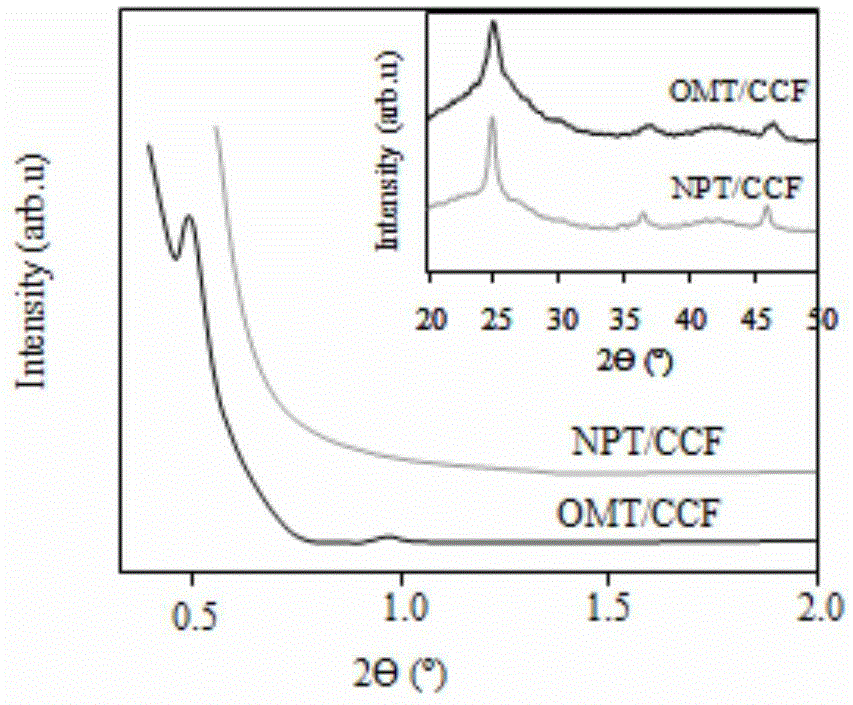

[0048] Embodiment 1: at first sodium perfluorooctanoate (30g) and distilled water (60ml) form liquid crystal, secondly, adopt liquid phase method, with 60g purity be 99.0% titanium tetrachloride, 2g ferric nitrate, 60ml distilled water and 5ml concentrated hydrochloric acid alcohol (one A mixture of 35% concentrated hydrochloric acid and two parts by weight of 75% ethanol (the same below) is mixed, the pH value is controlled between 1-3, added into a three-necked bottle, and stirred evenly with a GS122 electronic constant speed stirrer. Then add the above-mentioned liquid crystal into the three-necked bottle to form a "liquid crystal-inorganic precursor" solution; in addition, put 11g of conductive carbon felt (10cm×7cm) into the sprayer, and the optimal distance between the nozzle and the conductive carbon felt is 40cm. Temperature 20°C, relative humidity 80%, spray pressure 2MPa, spray flow rate 0.01ml / min, spray volume 500ml / dm 2 . Obtain "liquid crystal-inorganic precurso...

Embodiment 2

[0050] Embodiment 2: at first sodium perfluorooctanoate (30g) and distilled water (60ml) form liquid crystal, secondly, adopt liquid phase method, after 60g purity is 99.0% titanium tetrachloride, 2g ferric nitrate, 60ml distilled water and 5ml concentrated hydrochloric acid alcohol are mixed , control the pH value between 1–3, add it into a three-necked bottle, and stir well with a GS122 electronic constant speed stirrer. Then add the liquid crystal into the three-necked bottle to form a "liquid crystal-inorganic precursor" solution; in addition, put 11g of conductive carbon felt (10cm×7cm) into the sprayer, the optimal distance between the nozzle and the conductive carbon felt is 40cm, and the internal temperature 20°C, relative humidity 85%, spray pressure 6MPa, spray flow rate 0.02ml / min, spray volume 400ml / dm 2 . Obtain "liquid crystal-inorganic precursor" / CF complex. Then it was put into a Soxhlet extractor, and the number of extractions was 2 times (the amount of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com