Oil-based drilling cutting treatment device and oil-based drilling cutting treatment method

An oil-based drilling cuttings and processing device technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as high efficiency and low cost, avoid secondary pollution, solve high cost, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

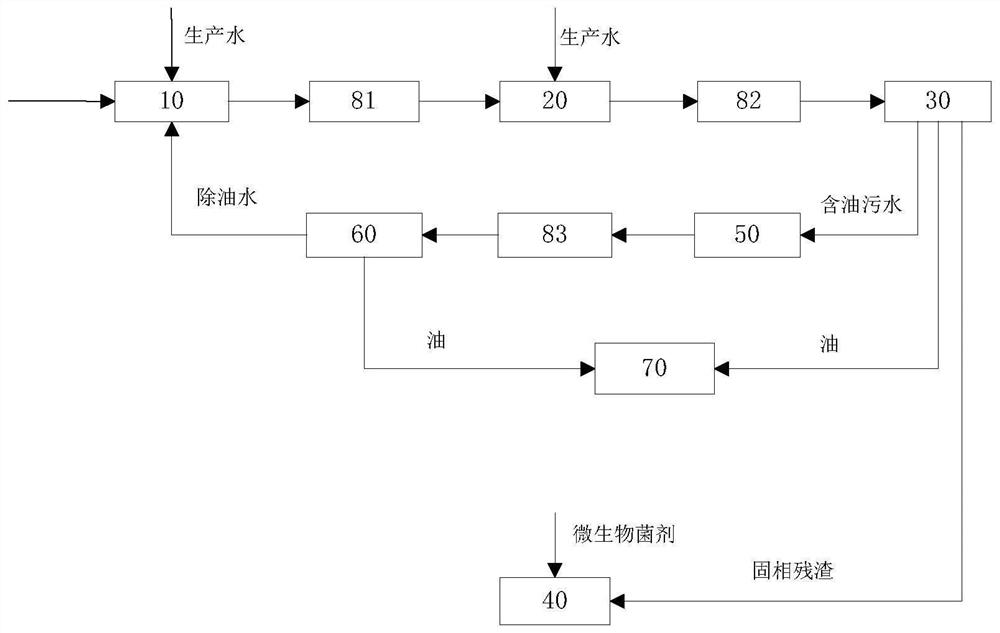

Method used

Image

Examples

Embodiment 1

[0043] Table 1 Properties of oil-based drilling cuttings

[0044] nature Oil content (%) Moisture content (%) Solid content (%) Oil-based cuttings A 14.75 5.10 80.15

[0045] Put the oil-based drilling cuttings with the parameters shown in Table 1 into the homogenizing tank. The oil-based drilling cuttings and water are mixed and diluted at a ratio of 1:2.5. The time is 5-10 minutes. After mixing, it is sent to the ultrasonic cleaning tank by mud pump for cleaning, and the production water is supplemented according to the ratio of oil-based drilling cuttings and water in the ratio of 1:15 to 18, and the power ultrasonic generator is turned on. The stirring blade speed of the ultrasonic cleaning tank is 40r / min. At ~45°C, wash for 15-20 minutes, and then send it to a three-phase centrifuge through a mud pump for three-phase separation of solid phase, oil phase and water phase. The speed of the three-phase centrifuge is 1800-2000r / min. The temperatu...

Embodiment 2

[0049] Table 3 Properties of oil-based drilling cuttings

[0050] nature Oil content (%) Moisture content (%) Solid content (%) Oil-based cuttings B 12.38 6.24 81.38

[0051] Put the oil-based drilling cuttings with the parameters shown in Table 3 into the homogenizing tank. The oil-based drilling cuttings and water are mixed and diluted at a ratio of 1:3.5. The time is 8-10 minutes. After mixing, it is sent to the ultrasonic cleaning tank for cleaning through the mud pump, and the power ultrasonic generator is turned on. The stirring blade of the ultrasonic cleaning tank rotates at a speed of 45r / min, and is cleaned at a temperature of 48-50°C for 15-20 minutes. Then it is sent into a three-phase centrifuge through a mud pump for three-phase separation of solid phase, oil phase and water phase, and the rotation speed of the three-phase centrifuge is 2200-2500r / min. The temperature of the microbial degradation tank was controlled within the range ...

Embodiment 3

[0055] Table 5 Properties of oil-based drilling cuttings

[0056] nature Oil content (%) Moisture content (%) Solid content (%) Oil-based cuttings C 15.74 4.32 79.94

[0057] Put the oil-based drilling cuttings with the parameters shown in Table 5 into the homogenizing tank. The oil-based drilling cuttings and water are mixed and diluted at a ratio of 1:4.5. The stirring blade speed in the homogenizing tank is 60-80r / min. 3 to 5 minutes. After mixing, it is sent into the ultrasonic cleaning tank through the mud pump, the power ultrasonic generator is turned on, the rotation speed of the stirring paddle is 45r / min, and the cleaning is performed at a temperature of 45-50°C for 12-15 minutes. Then it is sent to a three-phase centrifuge through a mud pump for three-phase separation of solid phase, oil phase and water phase. The centrifuge speed is 1500-1800r / min. The temperature of the microbial degradation tank was controlled within the range of 37°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com