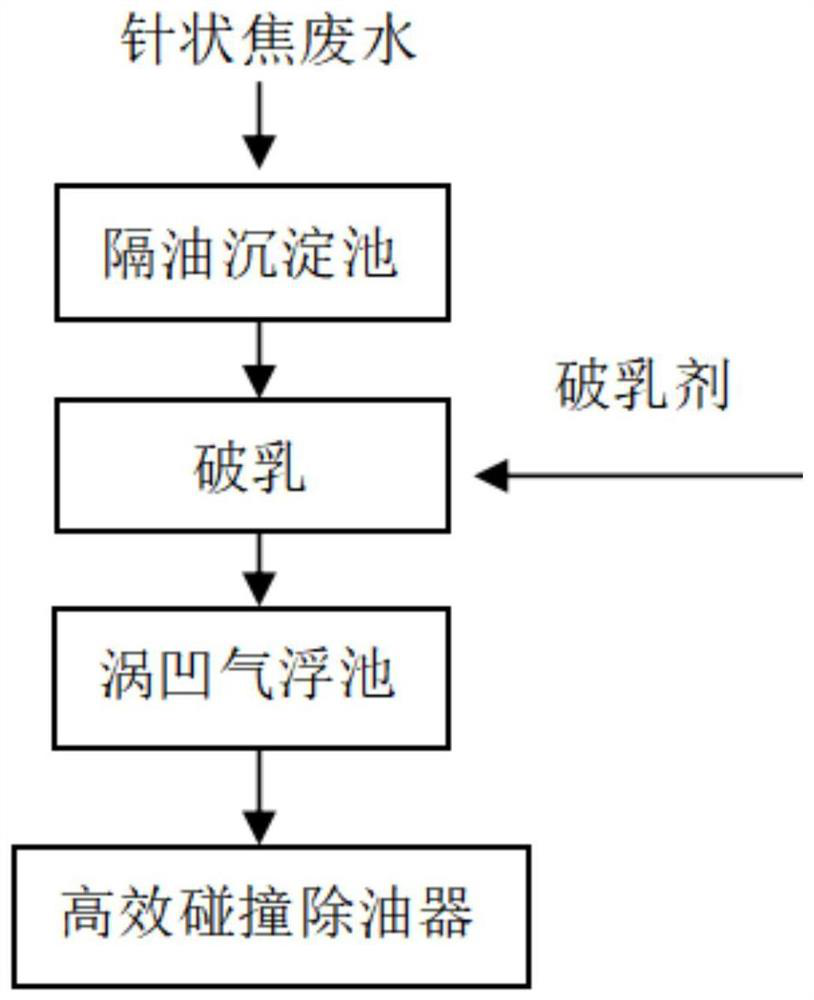

Oil separation and removal process for coal-based needle coke wastewater

A needle coke and waste water technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of reducing oil content, reducing oil concentration and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

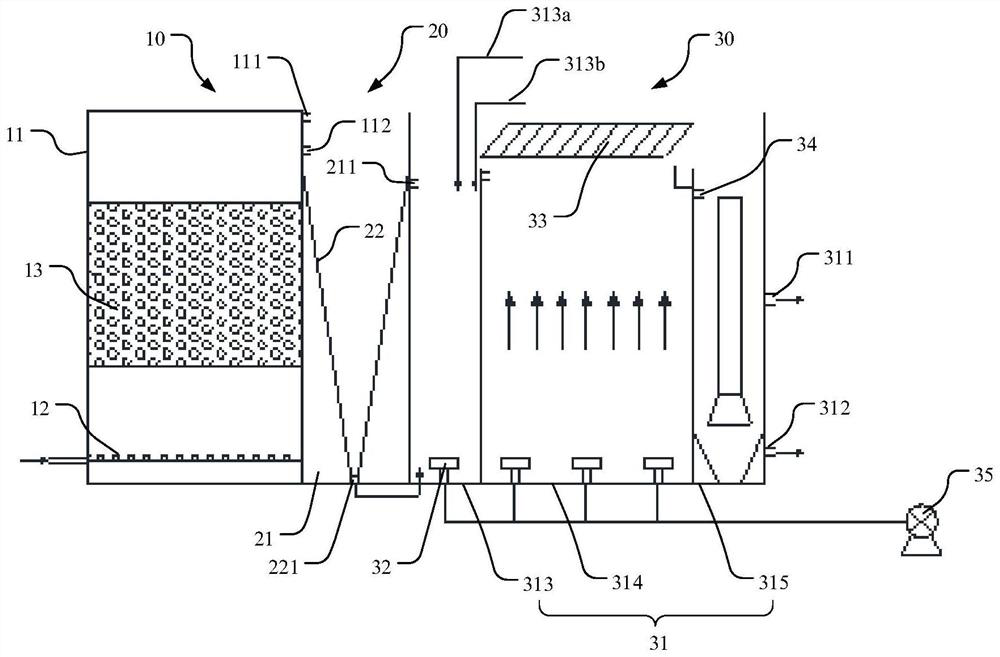

Method used

Image

Examples

preparation example 1

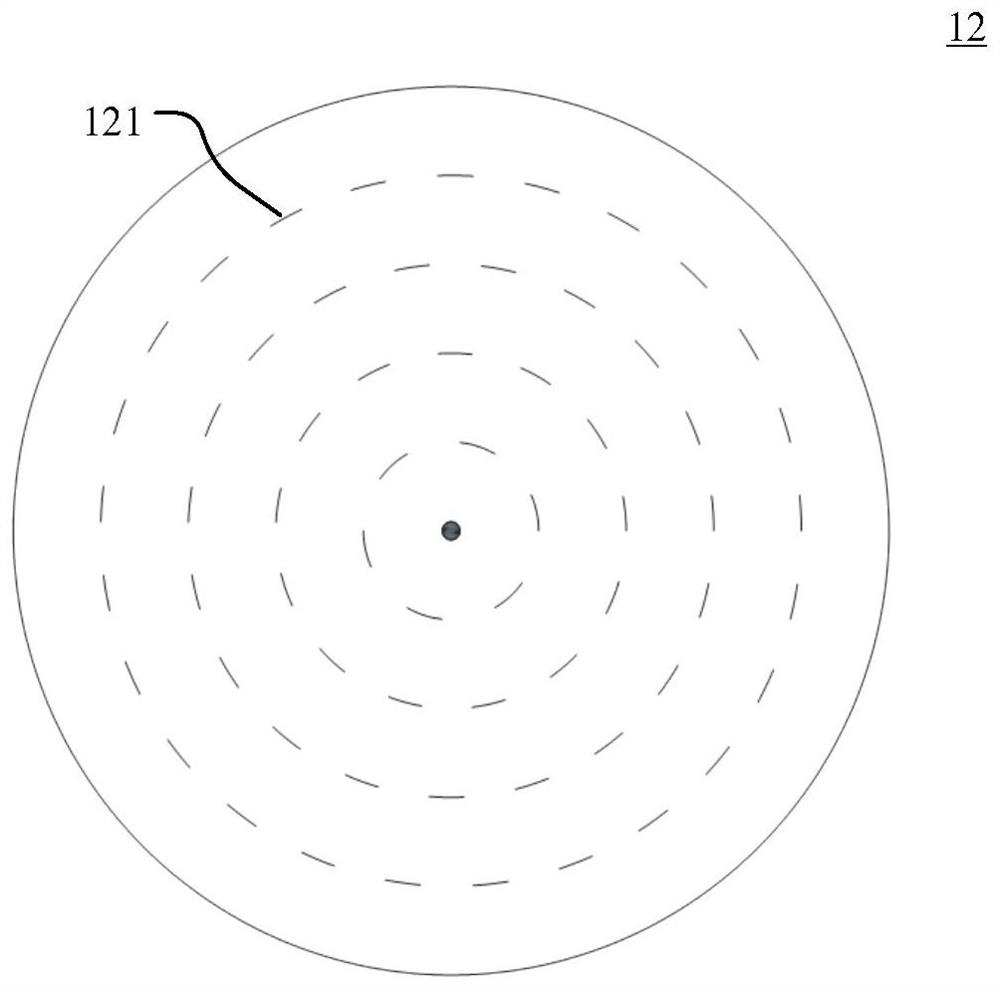

[0066] Immerse 100 parts of the honeycomb high-density polyethylene (HDPE) after surface cleaning in the acetone solution of 5 wt % benzophenone for 24 hours, take it out and dry it at 60 ° C to obtain a polyethylene material coated with a photosensitizer on the surface , and then dipped in a quartz tube filled with an acetone solution with a total mass concentration of 9.6 wt% of the grafted monomers, the grafted monomers are methyl methacrylate, isocenyl methacrylate, and acryloyloxyethyl cinnamate According to the mixture with a mass ratio of 3:3:1, the quartz tube containing the monomer solution was passed through nitrogen to remove oxygen in advance, and irradiated with a 400W high-pressure mercury lamp with a distance of 20cm and an irradiation time of 6h. After the reaction, the grafted modified polyethylene material was removed. , reflux extraction in acetone for 5 hours, fully remove the unreacted monomers on the surface of the modified polyethylene, monomer polymers a...

preparation example 2

[0068] Other conditions and operations were the same as those in Preparation Example 1, except that the ultraviolet light was irradiated for 10 h, and the grafting ratio of the finally obtained grafted modified polyethylene was 7.8%.

preparation example 3

[0070] Other conditions and operations were the same as those in Preparation Example 1, except that the ultraviolet light was irradiated for 3 hours, and the graft ratio of the finally obtained graft-modified polyethylene was 3.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com