Intelligent cyclic regeneration equipment for cutting fluid

A technology of cyclic regeneration and cutting fluid, applied in the direction of lubricating composition, etc., can solve the problems of increasing the cleaning time of dirty fluid, generating odor, corrosion, etc., to increase the filtering effect and service life, easy to use and replace, and reduce the cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

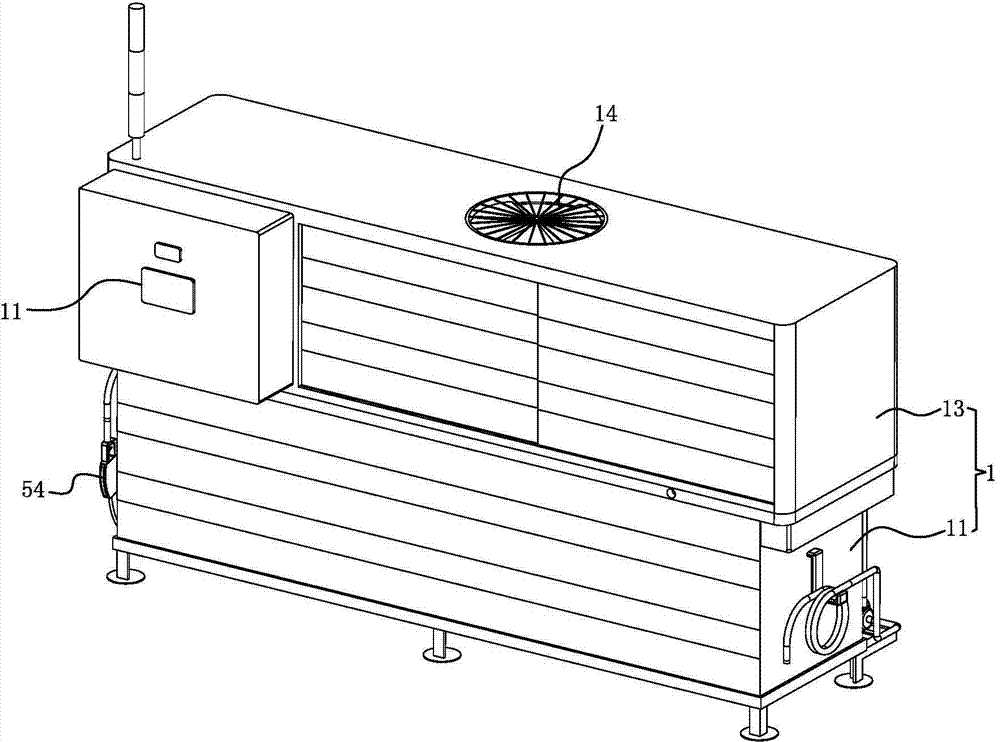

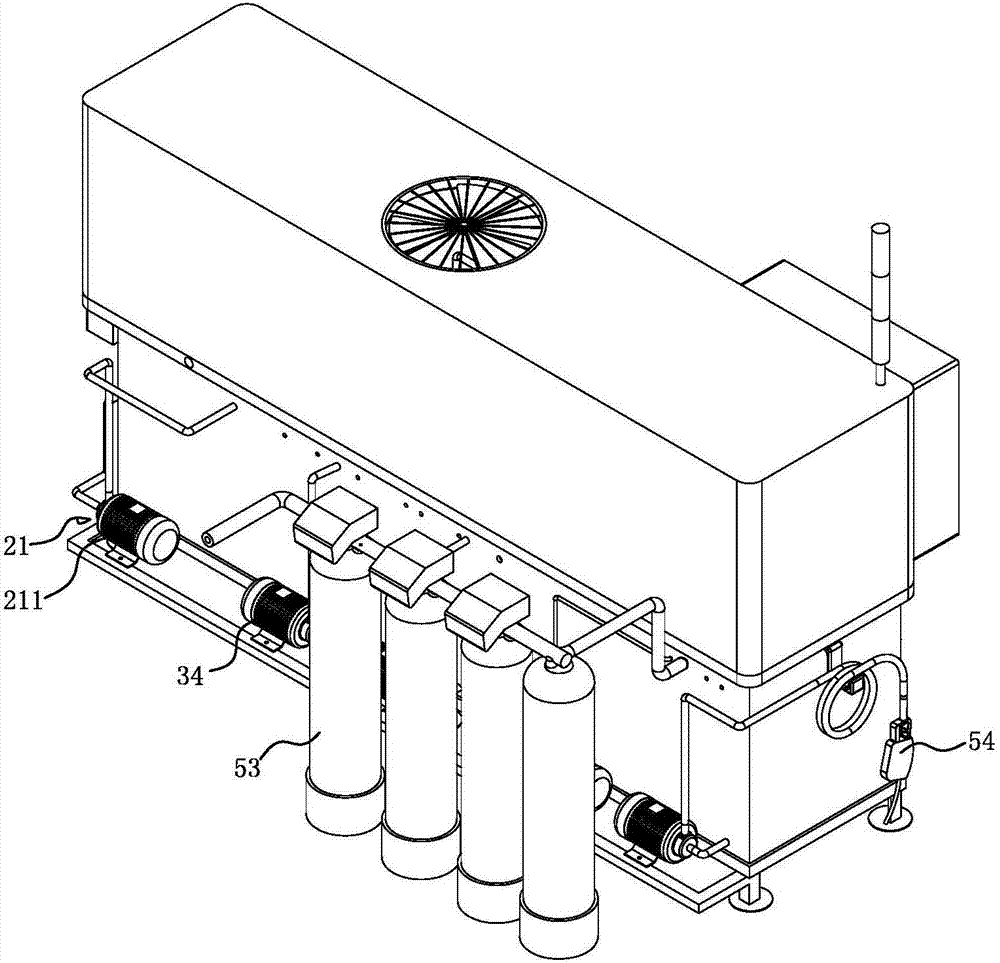

[0036] see Figure 1-7 As shown, it is a cutting fluid intelligent circulation regeneration equipment, which includes: a frame 1 and a first-stage filter device 2 installed on the frame 1, a second-stage filter device 3, a third-stage filter device 4 and a net Liquid tank 5.

[0037] The first-stage filter device 2 includes: a first suction device 21 installed on the frame 1 and used to suck in external cutting fluid and dirt, and a particle filter 22 for filtering chips and iron powder of the cutting fluid and dirt , a dirty liquid tank 23 for containing liquid and a first agitator 28 arranged in the dirty liquid tank 23, an alum water injection device 27 and a high-efficiency degreasing device 24.

[0038] The first suction device 21 includes: a first centrifugal pump 211 installed on the outside of the frame 1 and a first pipe body 212 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com