Coal gasification wastewater treatment method and treatment system

A technology of coal gasification wastewater and treatment methods, which is applied in the direction of oxidized water/sewage treatment, natural water treatment, multi-stage water treatment, etc. It can solve the problem of low water quality of evaporation water, failure to meet discharge standards, high concentration of scaling ions, etc. problems, to achieve the effect of prolonging the chemical cleaning cycle, simple structure, and good flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is used to illustrate the method and system for treating waste water from pressurized gasification of pulverized coal of the present invention.

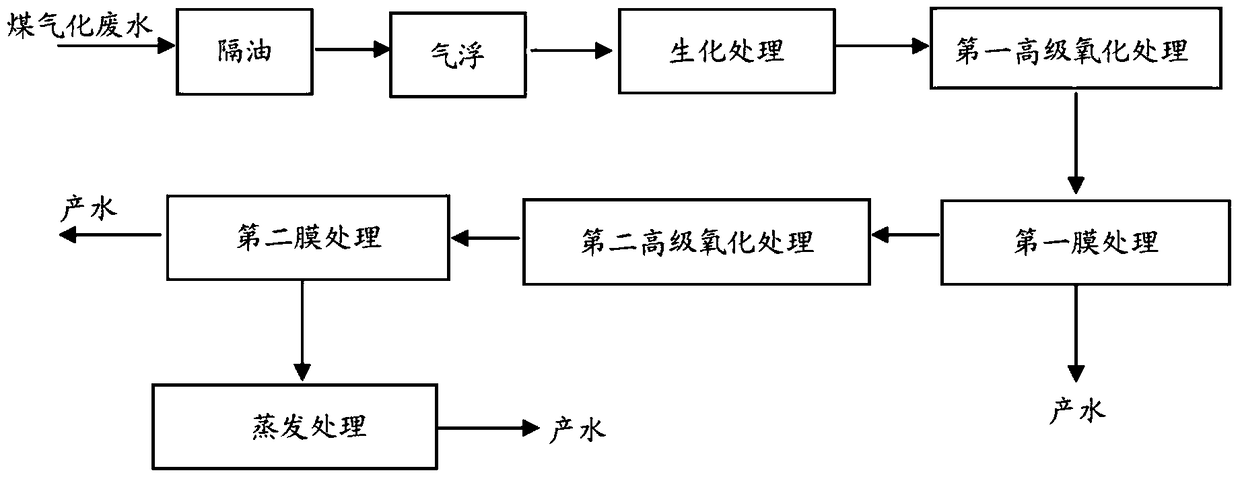

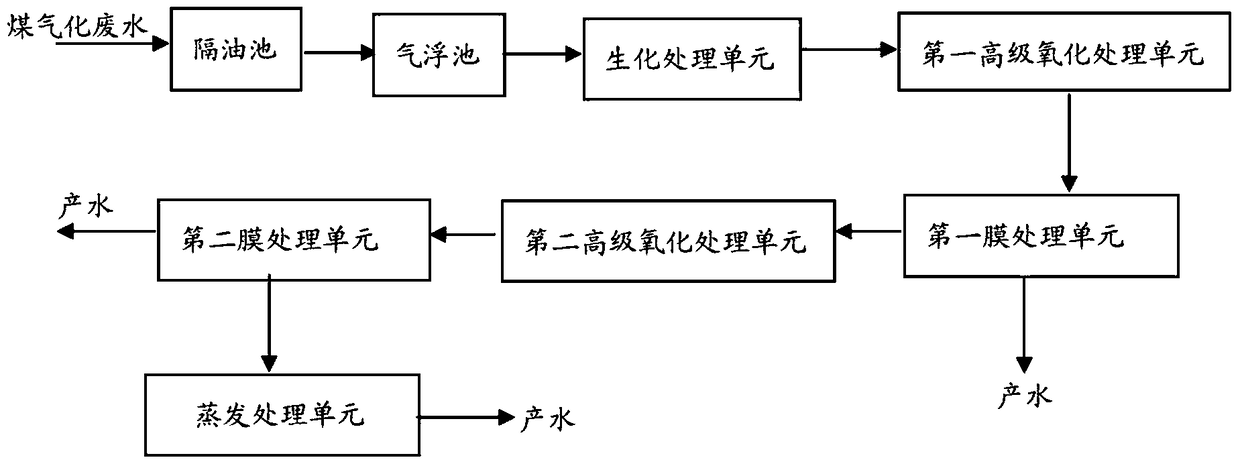

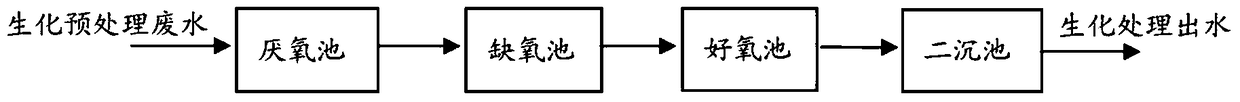

[0053] Such as figure 1 The coal gasification wastewater treatment system shown, the treatment system includes a regulating tank connected in sequence, a biochemical pretreatment unit, a biochemical treatment unit, a first advanced oxidation treatment unit, a first membrane treatment unit, a second advanced oxidation treatment unit, Second membrane treatment unit and evaporation unit. The above-mentioned equipment and structures can be connected sequentially through pipelines.

[0054] Parameters of coal gasification wastewater to be treated: pH value is 7-9, COD cr 3500-4500mg / L, TDS (total dissolved solids) 2000-2500mg / L, unit phenol (calculated as phenol) 250-550mg / L, polyphenol (calculated as phenol) 300-600mg / L, ammonia nitrogen ≤150mg / L.

[0055] In this embodiment, the working temperature of the proc...

Embodiment 2

[0129] This example is used to illustrate the present invention's screening of chemical dosage in the nitrogen flotation process.

[0130] The operation steps and other parameters of this embodiment are basically the same as those of Embodiment 1, the difference is the dosage of the chemicals in the chemical catalytic unit. The test data are shown in Table 1 below.

[0131] Table 1 The effect of the dosage of different chemicals on the effect of wastewater treatment

[0132]

[0133] The above results show that when the dosage of PAC is 40-60 mg / L and the dosage of PAM is 1.2-1.5 mg / L, the oil removal rate of the effluent can be significantly improved. When the dosage is lower than the selected range, the removal rate is not obvious or cannot meet the requirements of biochemical influent water quality; when the dosage is higher than the selected range, the removal rate is not obvious, which will cause economic waste.

Embodiment 3

[0135] This example is used to illustrate the screening of the present invention for a reasonable range of surface load in the nitrogen air flotation separation zone.

[0136] The operation steps and other parameters of this embodiment are basically the same as those of Embodiment 1, except that the surface load value is different. The test data are shown in Table 2 below.

[0137] Table 2 Effect of different surface loads on wastewater treatment effect

[0138]

[0139]

[0140] The above results show that the surface load is 6 ~ 8m 3 / m 2 When h is within the selected range, the oil removal rate of the effluent can be significantly improved. When the surface load is lower than the selected range, the removal rate is not obvious, which will cause economic waste. When the surface load is higher than the selected range, the removal rate is obviously reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| membrane flux | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com