Anode material applied to photoelectric degradation of tetracycline and preparation method of anode material

A technology of anode material and photoelectric degradation, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as increased maintenance costs, potential safety hazards, reduced sludge activity, etc., to reduce compounding The effect of reducing the speed, reducing the difficulty of the processing process, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

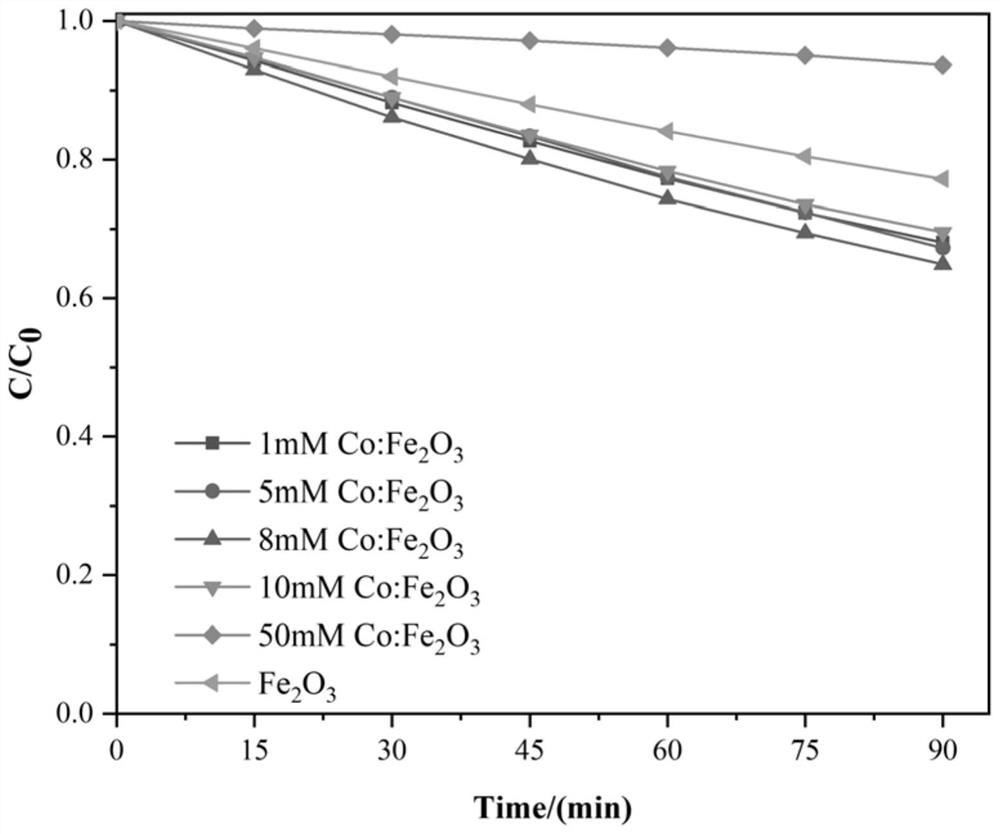

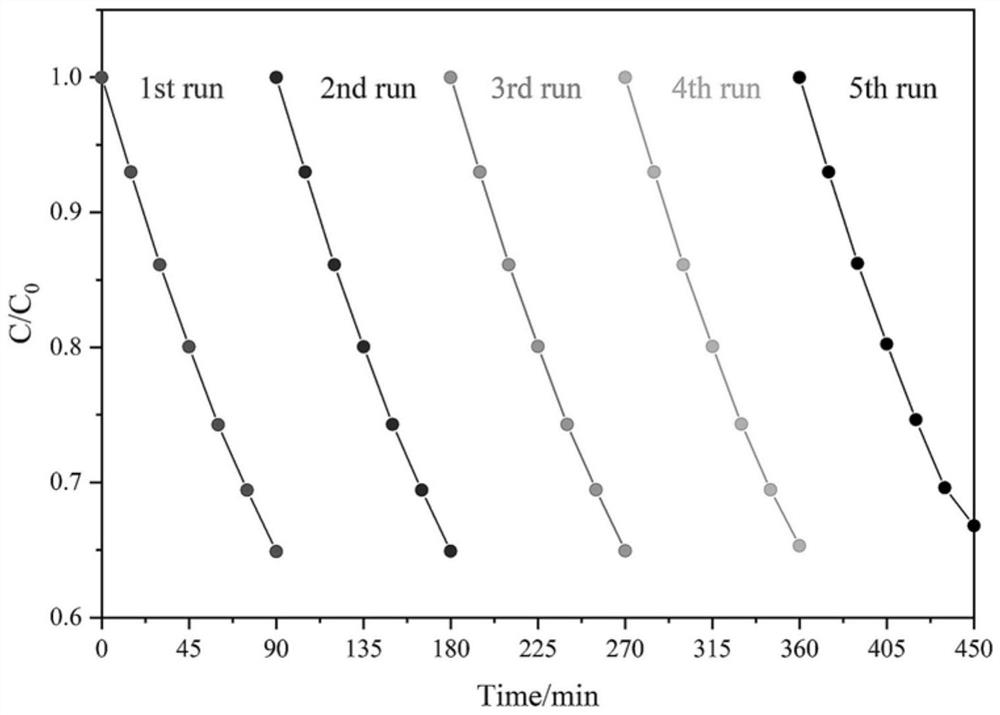

[0031] Co:α-Fe 2 o 3 Various parameters in the preparation process of the anode material, wherein cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) is added in a concentration range of 1 to 50mmol / L; the Co:α-Fe synthesized within this doping range 2 o 3 The anode material has a more beneficial degradation efficiency for tetracycline; in addition, the Co:α-Fe prepared by this method 2 o 3 In the actual degradation process, anode materials have high reuse rate and good degradation stability, and have broad development and application prospects.

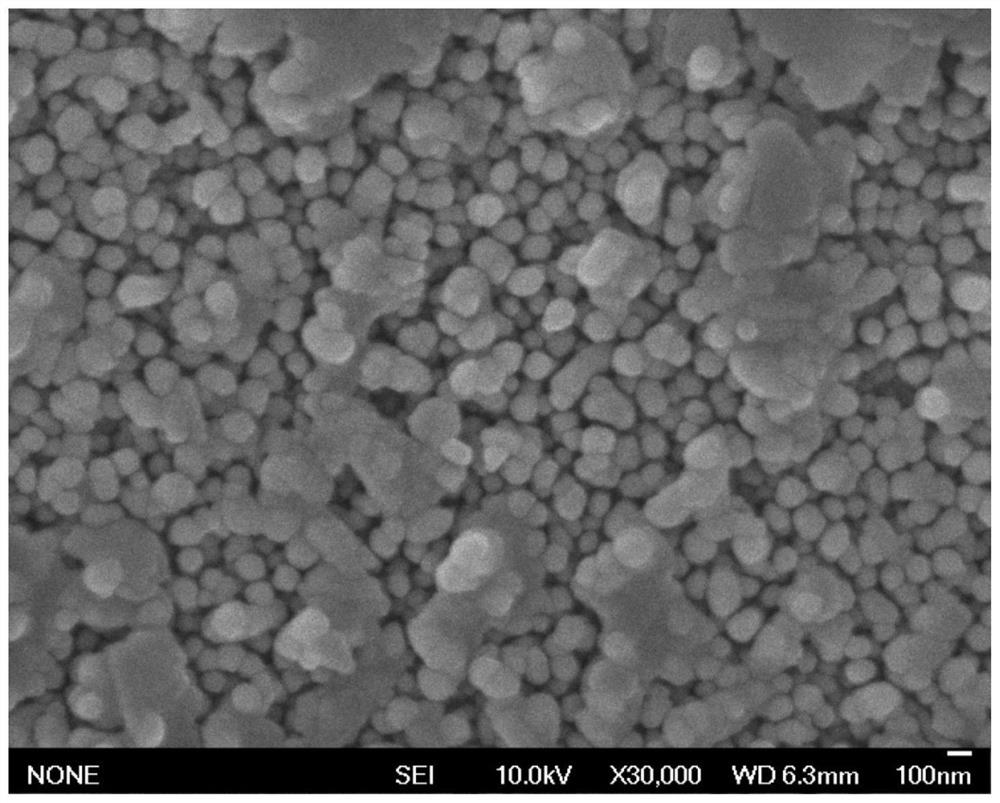

[0032] Among them, Co:α-Fe 2 o 3 The anode material is to place the cleaned FTO in the mixed solution, and the precursor is prepared by the hydrothermal method; then the precursor is annealed in the muffle furnace, and finally Co:α-Fe is obtained 2 o 3 anode material.

[0033] The role of each component: FTO is to provide growth sites for electrode materials. It can save the filtering operation when testing after tetracycline is d...

Embodiment 1

[0041] Co involved in the embodiments of the present invention: α-Fe 2 o 3 The synthesis steps are as follows: intercept 4×2.2 cm of fluorine-doped SnO 2 Conductive glass (FTO), ultrasonically clean the intercepted FTO with acetone, ethanol, and deionized water successively (the ultrasonic cleaning time of acetone, ethanol, and deionized water is all 20 minutes); dry and set aside.

[0042] Weigh 17g of sodium nitrate (NaNO 3 ), 5.406g of ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 0.380g of cobalt chloride hexahydrate (CoCl 2 ·6H 2 (0) Add 200mL of deionized water after stirring and dissolving to obtain mixed solution A (containing 1mol / L NaNO in mixed solution A 3 , 0.10mol / L FeCl 3 ·6H 2 O and 0.008mol / L CoCl 2 ·6H 2 O).

[0043] Place the dried FTO in a 25mL polytetrafluoroethylene liner (note that the conductive side is placed downwards), and add an appropriate amount of mixed solution A until it just submerges the entire FTO. Put the Teflon-lined lid tightl...

Embodiment 2

[0047] 1mM Co involved in the present invention: α-Fe 2 o 3 , 5mM Co:α-Fe 2 o 3 , 10mM Co:α-Fe 2 o 3 , 50mM Co:α-Fe 2 o 3 , and α-Fe 2 o 3 All were prepared according to the steps of Example 1. where α-Fe 2 o 3 The difference of the synthetic preparation is that no CoCl is added 2 ·6H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com