Halogen-containing molecular sieve adsorbent and preparation method thereof

A molecular sieve and adsorbent technology, applied in the field of halogen-containing molecular sieve adsorbents and their preparation, can solve the problems of low adsorption capacity, poor regeneration stability, and low purification precision of adsorbents, and achieve good regeneration and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

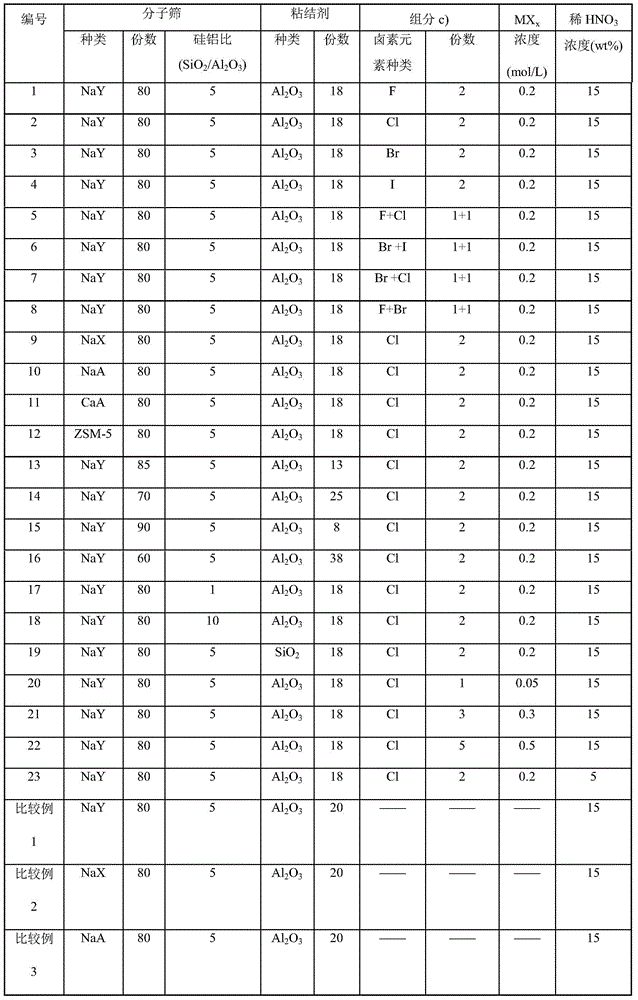

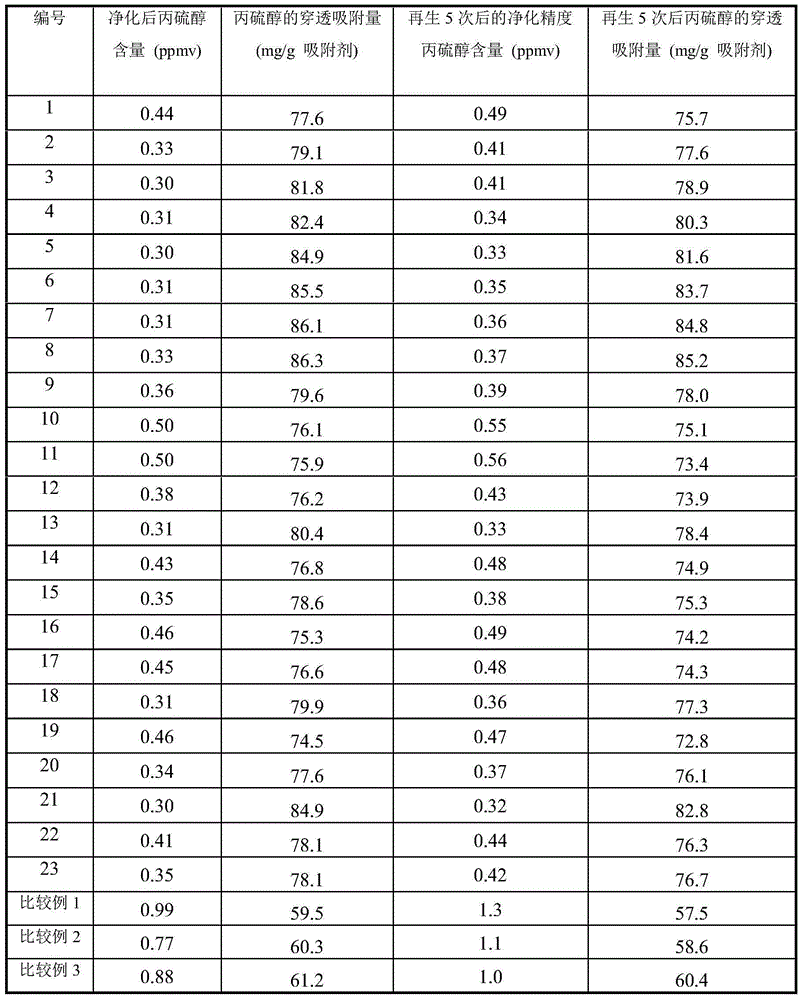

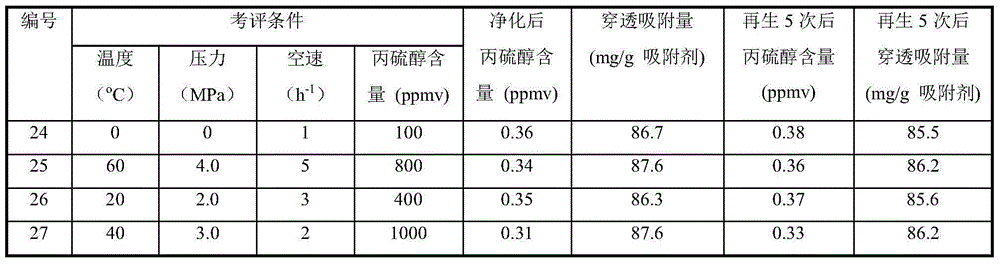

Examples

Embodiment 1

[0026] The preparation process of NaY molecular sieve adsorbent modified with fluorine element is as follows. First, accurately weigh 10 g of NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, 100 ml of dilute nitric acid solution with a mass percent concentration of 15% was prepared for subsequent use. Accurately weigh 2.5gAl 2 o 3 , will weigh Al 2 o 3 Mix well with the above-mentioned NaY molecular sieve raw powder. Take 7ml of dilute nitric acid solution with a mass percent concentration of 15%, slowly and evenly add it dropwise to the above mixture, and then extrude it with an extruder. The molded samples are dried or oven-dried for later use.

[0027] Prepare NH with a molar concentration of 0.2mol / L 4 F solution 100ml. Take the above NH 4 Sprinkle 4ml of solution F evenly on the above-mentioned formed molecular sieve carrier, and stir thoroughly. Dry it naturally, and bake it for 4 hours at 550°C in the air. Grinding and sieving ...

Embodiment 2

[0031] The preparation process of NaY molecular sieve adsorbent modified with chlorine element is as follows. First, accurately weigh 10 g of NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, 100 ml of dilute nitric acid solution with a mass percent concentration of 15% was prepared for subsequent use. Accurately weigh 2.5gAl 2 o 3 , will weigh Al 2 o 3 Mix well with the above-mentioned NaY molecular sieve raw powder. Take 7ml of dilute nitric acid solution with a mass percent concentration of 15%, slowly and evenly add it dropwise to the above mixture, and then extrude it with an extruder. The molded samples are dried or oven-dried for later use.

[0032] Prepare NH with a molar concentration of 0.2mol / L 4 Cl solution 100ml. Take the above NH 4 4ml of Cl solution was evenly sprinkled on the above-mentioned formed molecular sieve carrier, and fully stirred. Dry it naturally, and bake it for 4 hours at 550°C in the air. Grinding and sie...

Embodiment 3

[0036] The preparation process of NaY molecular sieve adsorbent modified with bromine element is as follows. First, accurately weigh 10 g of NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, 100 ml of dilute nitric acid solution with a mass percent concentration of 15% was prepared for subsequent use. Accurately weigh 2.5gAl 2 o 3 , will weigh Al 2 o 3 Mix well with the above-mentioned NaY molecular sieve raw powder. Take 7ml of dilute nitric acid solution with a mass percent concentration of 15%, slowly and evenly add it dropwise to the above mixture, and then extrude it with an extruder. The molded samples are dried or oven-dried for later use.

[0037] Prepare NH with a molar concentration of 0.2mol / L 4 Br solution 100ml. Take the above NH 4 4ml of Br solution was evenly sprinkled on the above-mentioned formed molecular sieve carrier, and stirred thoroughly. Dry it naturally, and bake it for 4 hours at 550°C in the air. Grinding and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com