Millimeter channel type continuous preparation system

A preparation system, channel-type technology, applied in the field of millimeter-channel continuous preparation systems, can solve the problems of easy blockage of pipelines, low product flow rate, high processing cost of microchannel reactors, etc., to promote turbulent flow and heat transfer qualitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

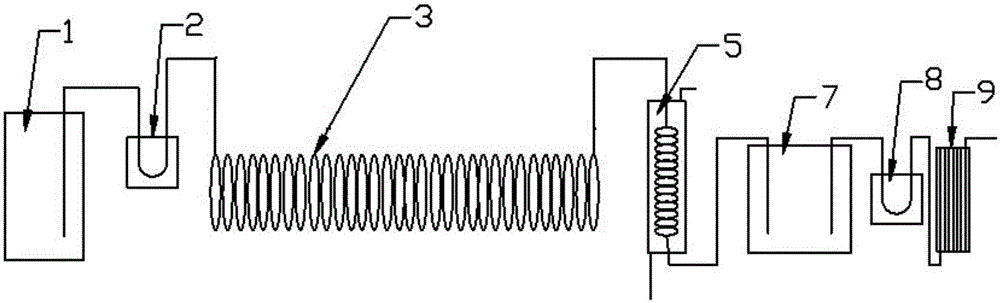

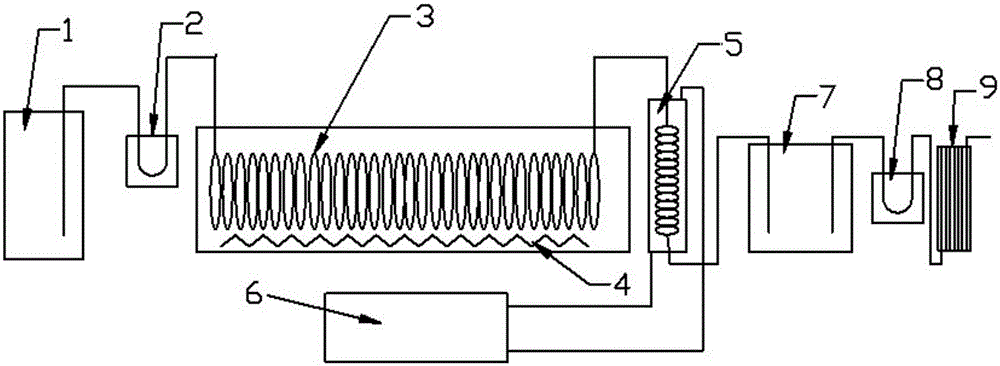

[0028] The preparation system used in this example is as figure 2 As shown, the details are as follows:

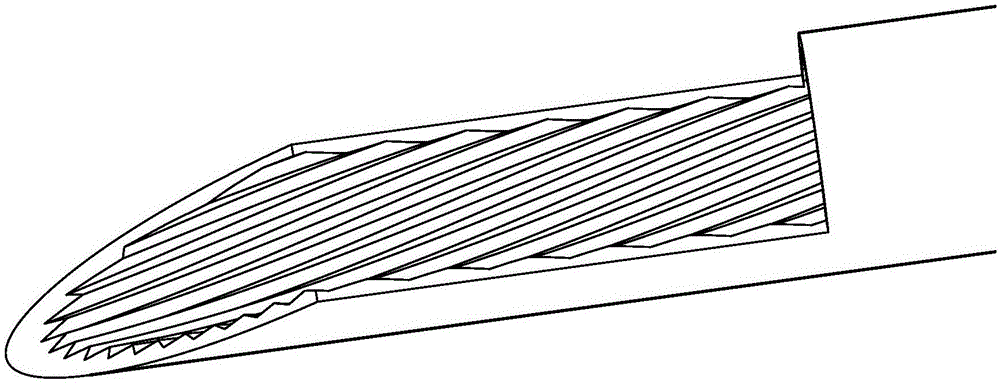

[0029] The output end of the raw material tank 1 is connected to the input end of the peristaltic pump 2 through a pipeline, and the output end of the peristaltic pump 2 is connected to the input end of the channel reaction tube 3 through a pipeline; the channel reaction tube 3 is arranged in the oil bath device 4 , the effect of oil bath device 4 is to control channel type reaction tube 3 at the reaction temperature of setting; Channel type reaction tube 3 is spiral tube type, and internal diameter is 6mm, and length is 27m, and inner wall is provided with internal screw thread (such as image 3 As shown), the screw pitch is 1mm, which can promote uniform mass transfer; the output end of the channel type reaction tube 3 is connected with the input end of the condensing tube 5 through a pipeline, and the reactant in the condensing tube is cooled by a circulating water bat...

Embodiment 2

[0038] The difference from Example 1 is that in this example, two millimeter-channel continuous preparation systems are used in series, which can be used for the synthesis of core-shell structure nanocrystals. In this example, CuInS 2 / ZnS nanocrystal preparation is described in detail:

[0039] The first preparation system is the same as in Example 1; the difference between the second preparation system and the first preparation system is that the inner diameter of the channel reaction tube 3 is 6mm, the length is 81m, and the internal thread pitch is 5mm.

[0040] Steps 1-4 of the preparation process of this example use the first preparation system, and the specific operations are the same as steps 1-4 of Example 1.

[0041] 5. The CuInS obtained from the first preparation system 2 The nanocrystal solution is directly added in the raw material tank of the second preparation system (afterwards in the description of this embodiment, all components refer to the components of ...

Embodiment 3

[0047] The difference from Example 1 is that the inner diameter of the channel reaction tube 3 is 10 mm. The size, uniformity, and dispersibility of the resulting product are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com