Preparation method of nanochain solar cell

A solar cell and nanochain technology, applied in the field of solar cells, can solve the problems of difficulty in obtaining nanowires, complicated preparation process, etc., and achieve the effect of simple preparation method and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

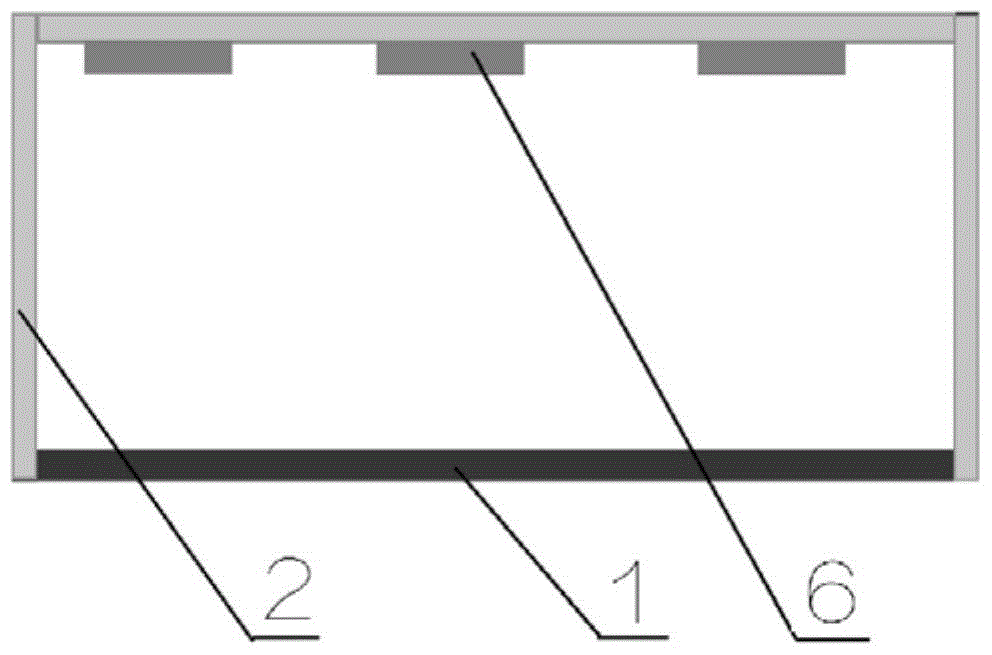

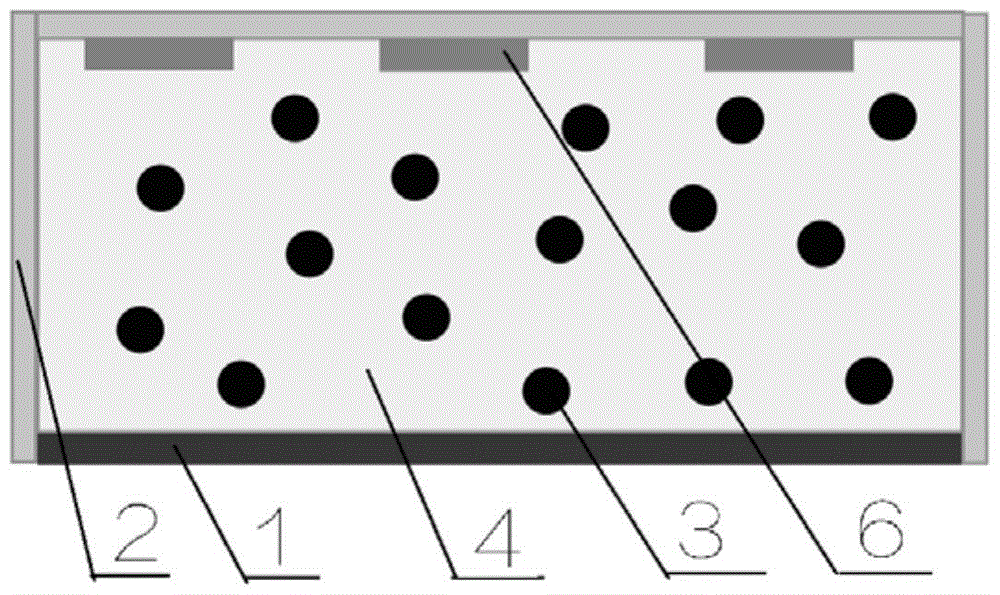

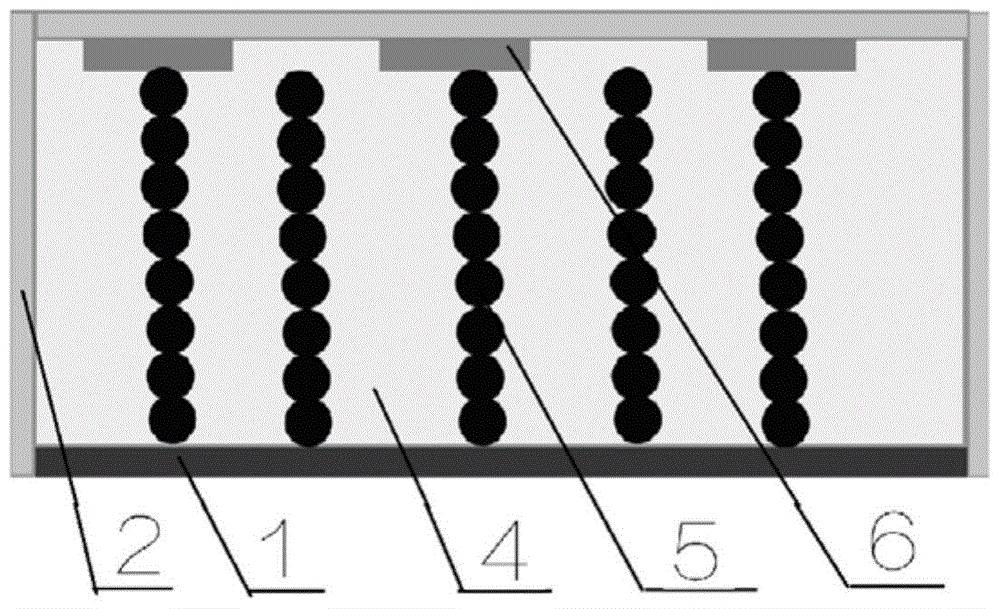

[0040] Step 1) Preparation of electrodes

[0041] Taking the pulsed laser deposition method as an example, other methods such as magnetron sputtering, sol-gel method, etc. may also be used. to La 0.7 Sr 0.3 MnO 3 As the lower electrode as an example, other materials can also be used, such as conductive oxide ITO, La 0.5 Sr 0.5 CoO 3 etc. Or Metal, Au, Pt, Ag etc. First in SrTiO 3 Substrates (of course, other types of substrates, silicon wafers, glass, etc.) are ultrasonically cleaned in acetone and alcohol, and dried; the substrate table is polished with sandpaper, and cleaned, and the dried The substrate is glued on the substrate stage with thermally conductive silver, and then the substrate is blocked with a corresponding mask according to the shape, size and number of electrodes required. After drying, put it in the cavity on the heating table and start vacuuming. Wait until the air pressure reaches 10 -4 Pa, start heating the substrate stage. Note that it should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com