A kind of assay method of polyethylene glycol content in polycarboxylate superplasticizer macromonomer

A technology of polyethylene glycol and water reducing agent, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of reducing sample volume, short inspection cycle and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Method validation test

[0026] 1. Instruments and reagents:

[0027] Shimadzu LC-20AT liquid chromatograph, labsolutions LC workstation; ME204E electronic analytical balance (Mettler Toledo)

[0028] Superplasticizer macromonomer sample; polyethylene glycol 4000 reference substance (Agilent); acetonitrile (Thermo Fisher); laboratory water is ultrapure water

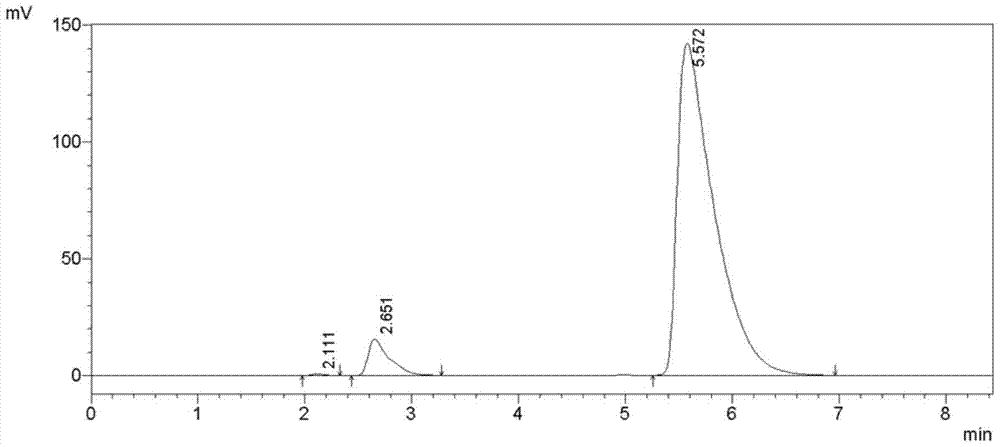

[0029] 2. Methods and results

[0030] 2.1 Chromatographic conditions: chromatographic column is GLInterSutain-C 18 (4.6mm*250mm*5μm), the mobile phase is acetonitrile:water (45:55), the flow rate is 1mL / min, the column temperature is 35°C, the injection volume is 5μL, and the number of theoretical plates is not low based on polyethylene glycol in 2000.

[0031] 2.2 Preparation of the reference substance solution: Weigh 20 mg of polyethylene glycol 4000 to a 50 ml measuring bottle, accurately weigh it, add mobile phase to dissolve and dilute to the mark to obtain the reference substance solution.

[0032] 2.3...

Embodiment 2

[0042] Comparative test with chemical method

[0043] 1. Instruments and reagents:

[0044] Shimadzu LC-20AT liquid chromatograph, labsolutions LC workstation; ME204E electronic analytical balance (Mettler Toledo).

[0045] Macromonomer samples of water-reducing agents from 5 different companies; polyethylene glycol 4000 reference substance (Agilent); acetonitrile (Thermo Fisher); laboratory water was ultrapure water.

[0046] 2. Methods and results

[0047] 2.1 Chromatographic conditions: chromatographic column is GLInterSutain-C 18(4.6mm*250mm*5μm), the mobile phase is acetonitrile: water (45:55), the flow rate is 1mL / min, the column temperature is 35°C, the injection volume is 5μL, and the number of theoretical plates is not low based on polyethylene glycol in 2000.

[0048] 2.2 Preparation of reference substance solution: Weigh 20 mg of polyethylene glycol 4000 into a 50 ml measuring bottle, weigh accurately, add mobile phase to dissolve and dilute to the mark to obtai...

Embodiment 3

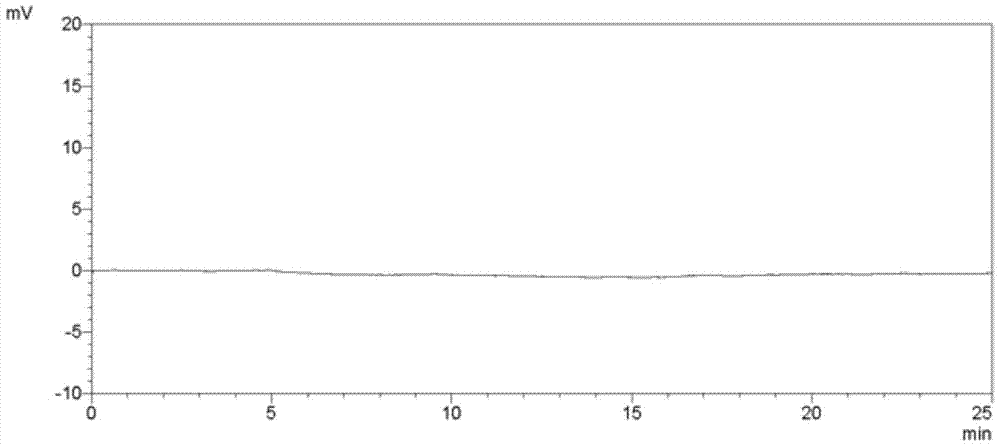

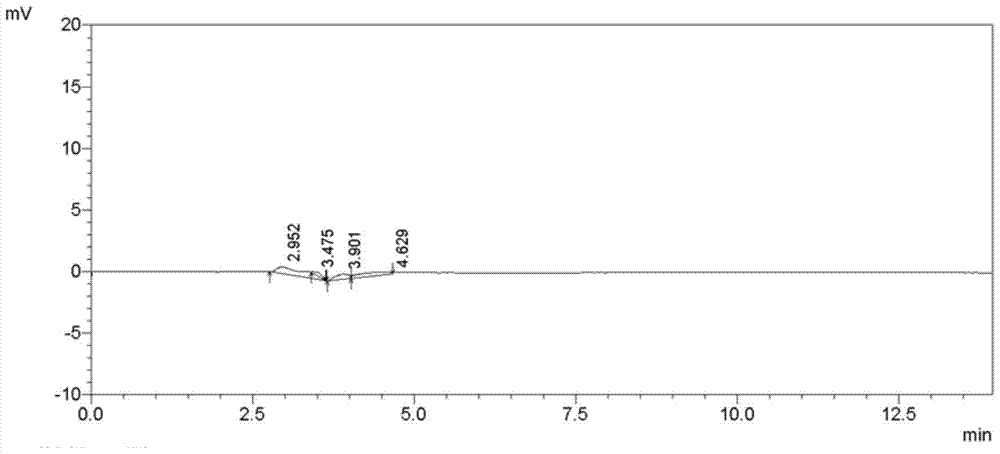

[0054] Blank sample comparison test

[0055] 1. Instruments and reagents:

[0056] Shimadzu LC-20AT liquid chromatograph, labsolutions LC workstation; ME204E electronic analytical balance (Mettler Toledo)

[0057] Superplasticizer macromonomer, acetonitrile (Thermo Fisher), methanol (Thermo Fisher) laboratory water is ultrapure water

[0058] 2. Methods and results

[0059] 2.1 Chromatographic condition 1: chromatographic column is GLInterSutain-C 18 (4.6mm*250mm*5μm), the mobile phase is acetonitrile: water (45:55), the flow rate is 1mL / min, the column temperature is 35°C, the injection volume is 5μL, and the number of theoretical plates is not low based on polyethylene glycol in 2000.

[0060] 2.2 Chromatographic conditions 2: The chromatographic column is GLInterSutain-C18 (4.6mm*250mm*5μm), the mobile phase is methanol:water (45:55), the flow rate is 1mL / min, the column temperature is 35°C, the injection volume is 5μL, the theoretical The number of plates is not less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com