Complex enzyme preparation for extracting effective plant components and method for preparing complex enzyme preparation

A technology of plant active ingredients and compound enzyme preparations, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of complex production processes, inconvenient mastery, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

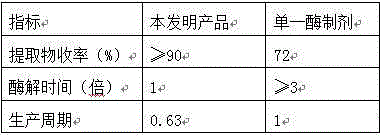

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

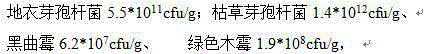

[0061] Preparation of Plant Extract Compound Enzyme Preparation

[0062] (1) The source of each strain:

[0063] Bacillus licheniformis Bacillus licheniformis , No. CGMCC1970;

[0064] Bacillus subtilis Bacillus subtilis , No. AS1.1229;

[0065] Aspergillus niger Aspergillus niger , No. IFFI.02439;

[0066] Trichoderma viride Trichodermaviride , No. CCTCCAF.93252.

[0067] (2) Slant culture:

[0068] Bacillus licheniformis slant medium (g / L): beef extract 5, peptone 10, yeast extract 5, NaCl5, agar 30, tap water, pH 7.5, cultured statically at 30°C for 24 hours;

[0069] Bacillus subtilis slant medium (g / L): peptone 10, beef extract 5, sodium chloride 5, agar 20, pH value 7.2, static culture at 30°C for 24 hours;

[0070] Aspergillus niger species use slant medium (g / L): Potato 200, glucose 20, dipotassium hydrogen phosphate 3, magnesium sulfate heptahydrate 1.5, natural pH, static culture at 0°C for 48 hours;

[0071] Trichoderma viride slant medium (g / L): sodium...

Embodiment 2

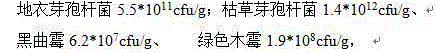

[0093] Preparation of Plant Extract Compound Enzyme Preparation

[0094] (1) The source of each strain:

[0095] Bacillus licheniformis Bacillus licheniformis , No. CGMCC1970;

[0096] Bacillus subtilis Bacillus subtilis , No. AS1.1229;

[0097] Aspergillus niger Aspergillus niger , No. IFFI.02439;

[0098] Trichoderma viride Trichodermaviride , No. CCTCCAF.93252.

[0099] (2) Slant culture:

[0100] Bacillus licheniformis slant medium (g / L): beef extract 5, peptone 10, yeast extract 5, NaCl5, agar 30, tap water, pH 7.5, static culture at 28°C for 20 hours;

[0101] Bacillus subtilis use slant medium (g / L): peptone 10, beef extract 5, sodium chloride 5, agar 20, pH value 7.2, static culture at 28°C for 20 hours;

[0102] Aspergillus niger species use slant medium (g / L): Potato 200, glucose 20, dipotassium hydrogen phosphate 3, magnesium sulfate heptahydrate 1.5, natural pH, static culture at 28°C for 20 hours;

[0103] Trichoderma viride slant medium (g / L): sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com