High-capacity organic-inorganic composite hydrogen storage material and preparation method thereof

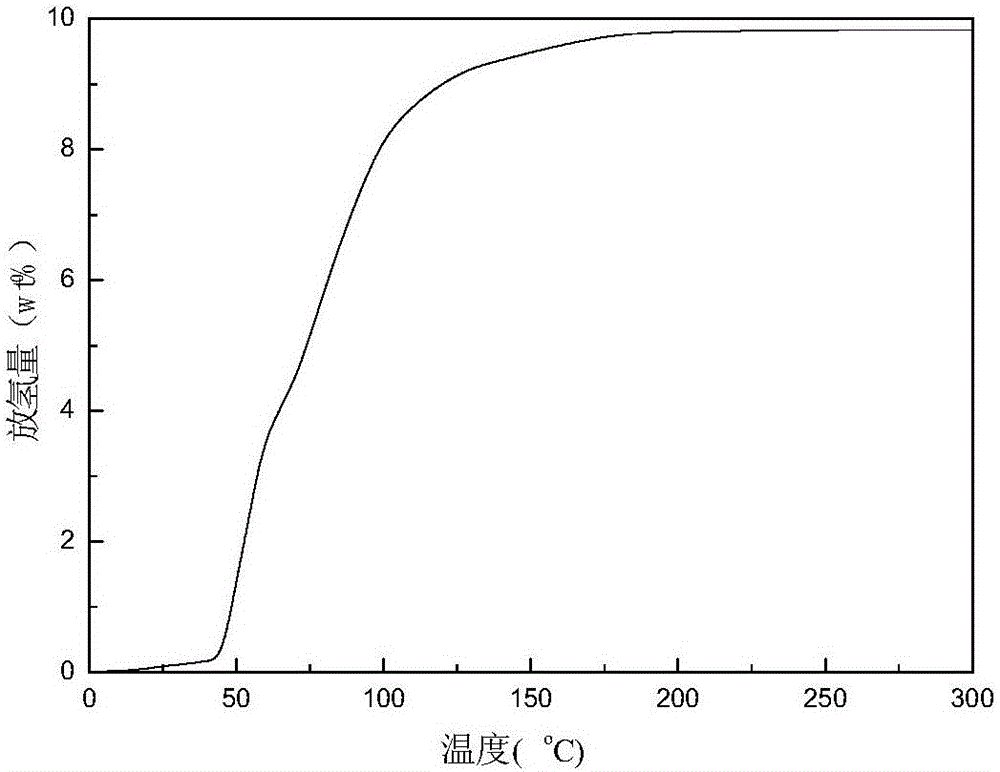

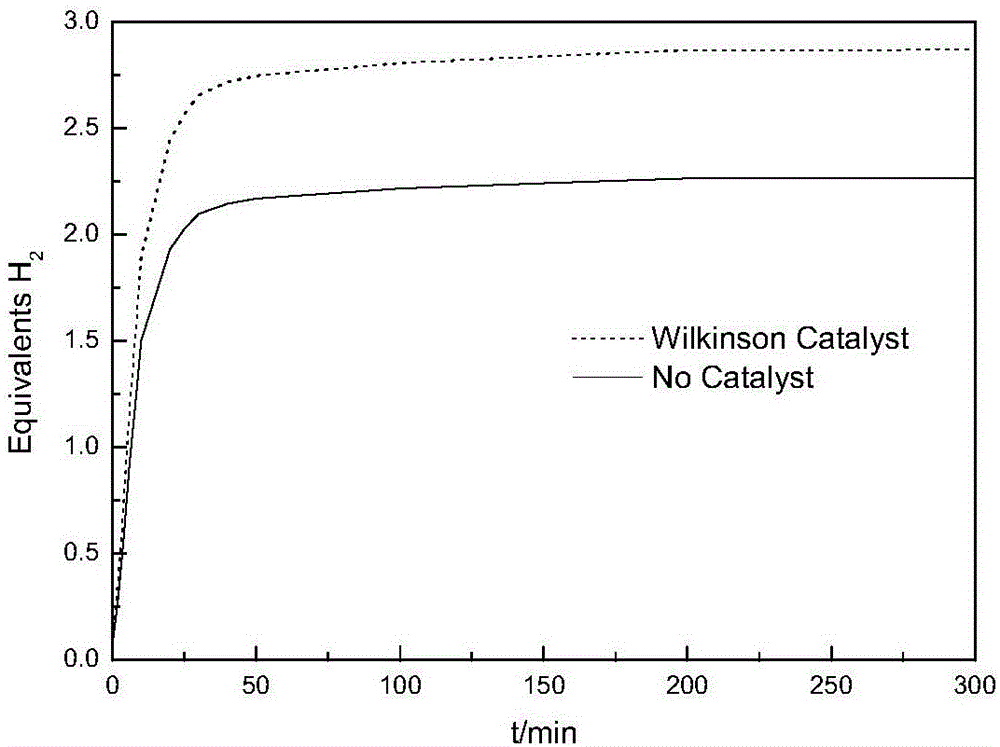

A technology of inorganic composite and hydrogen storage materials, applied in the production of hydrogen, etc., can solve the problems of low hydrogen storage efficiency, slow hydrogen desorption rate, poor dispersion performance, etc., and achieve high hydrogen storage capacity, favorable release, and hydrogen desorption temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

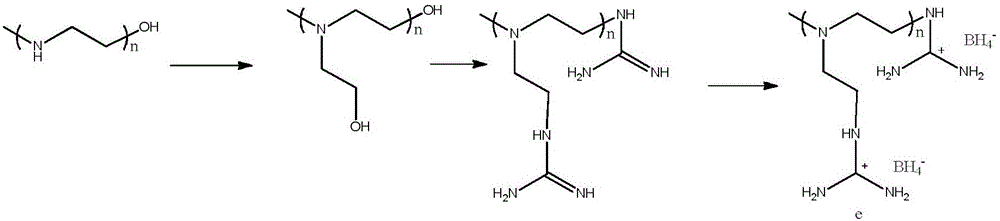

[0035]Weigh 10 g of polyethyleneimine (molecular weight: 10,000) and 10 g of cetyl ammonium bromide, dissolve them in 100 mL of ethanol at a temperature of 80° C., and stir to fully dissolve them. After stirring at constant temperature for 2 hours, add 25 g of ethyl orthosilicate to the reaction solution, and continue to stir at a temperature of 25 ° C for 12 hours; after the above reaction is completed, filter to obtain an organic-inorganic hybrid material;

[0036] Then add stoichiometric ratio of bromoethanol to the obtained organic-inorganic hybrid material, stir and react with potassium carbonate at 80°C for 24 hours, filter the precipitate, wash with water, and dry, and then dissolve the dried polymer in anhydrous dichloromethane Add 1.5 equivalents of methanesulfonyl chloride and triethylamine to react for 2 hours, then spin dry the solvent, extract with dichloromethane, dry, then add guanidine and triethylamine, react overnight at 25°C, filter and wash with water to obt...

Embodiment 2

[0039] Weigh 10 g of polyethyleneimine (molecular weight: 50,000) and 10 g of cetyl ammonium bromide, dissolve them in 100 mL of ethanol at a temperature of 80° C., and stir to fully dissolve them. After stirring at constant temperature for 2 hours, add 25 g of tetraethyl orthosilicate into the reaction solution, and continue to stir at 105°C for 12 hours; after the above reaction is completed, filter to obtain an organic-inorganic hybrid material;

[0040] Then add stoichiometric ratio of bromoethanol to the obtained organic-inorganic hybrid material, stir and react with potassium carbonate at 80°C for 24 hours, filter the precipitate, wash with water, and dry, and then dissolve the dried polymer in anhydrous dichloromethane Add 1.5 equivalents of methanesulfonyl chloride and triethylamine to react for 2 hours, then spin dry the solvent, extract with dichloromethane, dry, then add guanidine and triethylamine, react overnight at 25°C, filter and wash with water to obtain the am...

Embodiment 3

[0045] Weigh 10 g of PAH and 10 g of cetyl ammonium bromide, dissolve them in 100 mL of ethanol at a temperature of 80° C., and stir to fully dissolve them. After stirring at constant temperature for 2 hours, add 25 g of ethyl orthosilicate to the reaction solution, and continue to stir at a temperature of 110 ° C for 12 hours; after the above reaction is completed, filter to obtain an organic-inorganic hybrid material;

[0046] Then add stoichiometric ratio of bromoethanol to the obtained organic-inorganic hybrid material, stir and react with potassium carbonate at 80°C for 24 hours, filter the precipitate, wash with water, and dry, and then dissolve the dried polymer in anhydrous dichloromethane Add 1.5 equivalents of methanesulfonyl chloride and triethylamine to react for 2 hours, then spin dry the solvent, extract with dichloromethane, dry, then add guanidine and triethylamine, react overnight at 25°C, filter and wash with water to obtain the amino group Functionalized pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com