Glass substrate optical display infra-red sensor

An infrared sensor, glass substrate technology, applied in the field of sensing elements, can solve the problems of reducing infrared detection sensitivity, micro-beam reflector jitter, optical readout noise, etc., to avoid infrared energy loss, eliminate thermal crosstalk, and eliminate frame structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

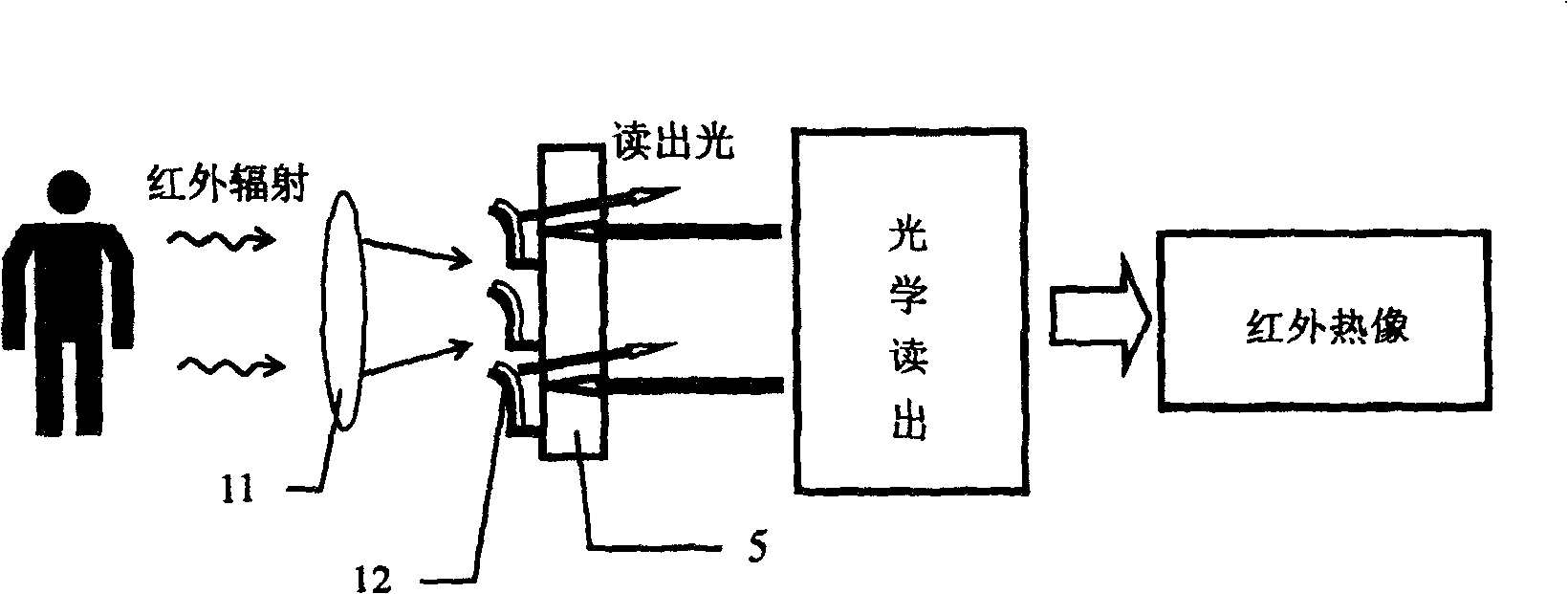

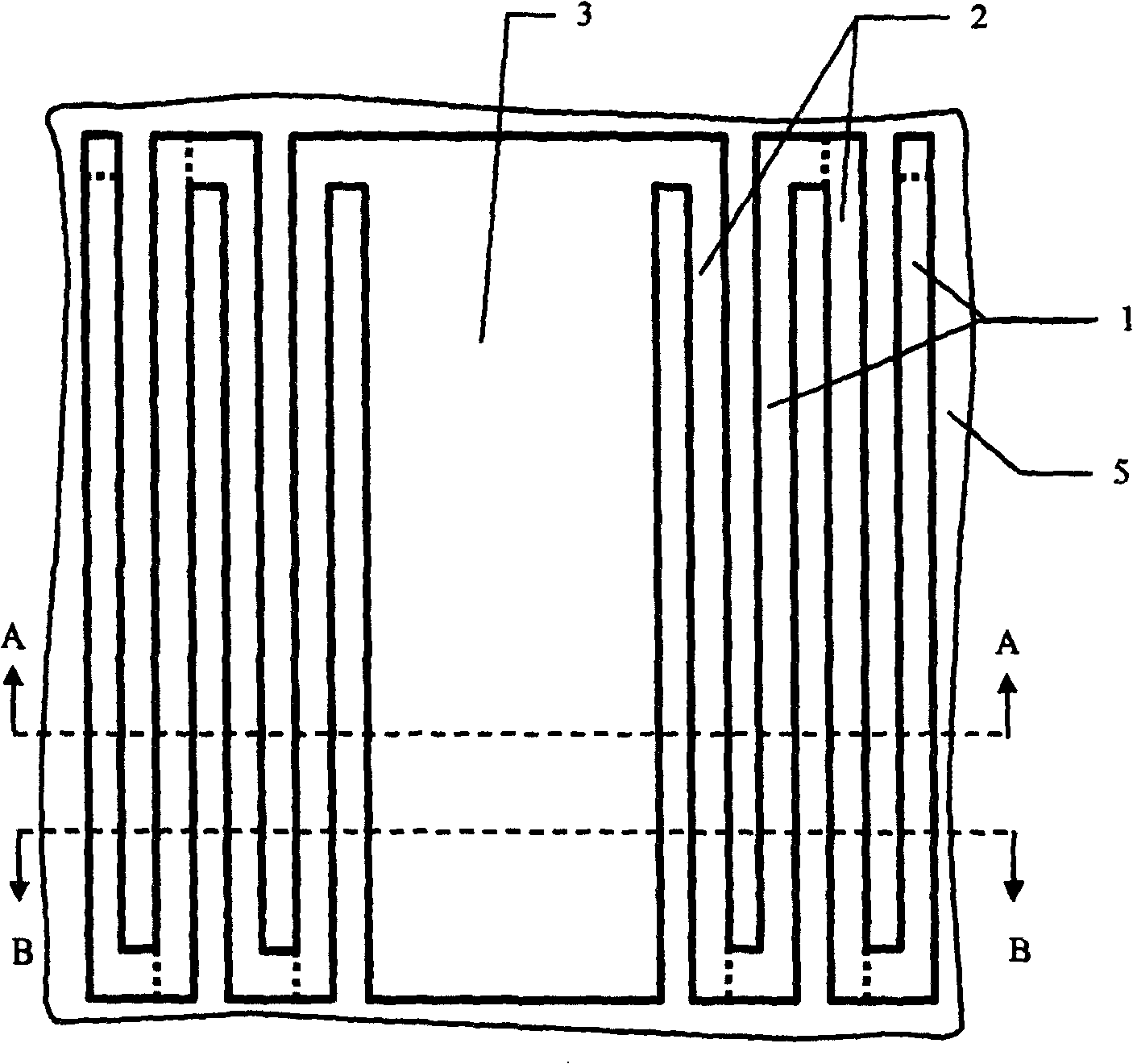

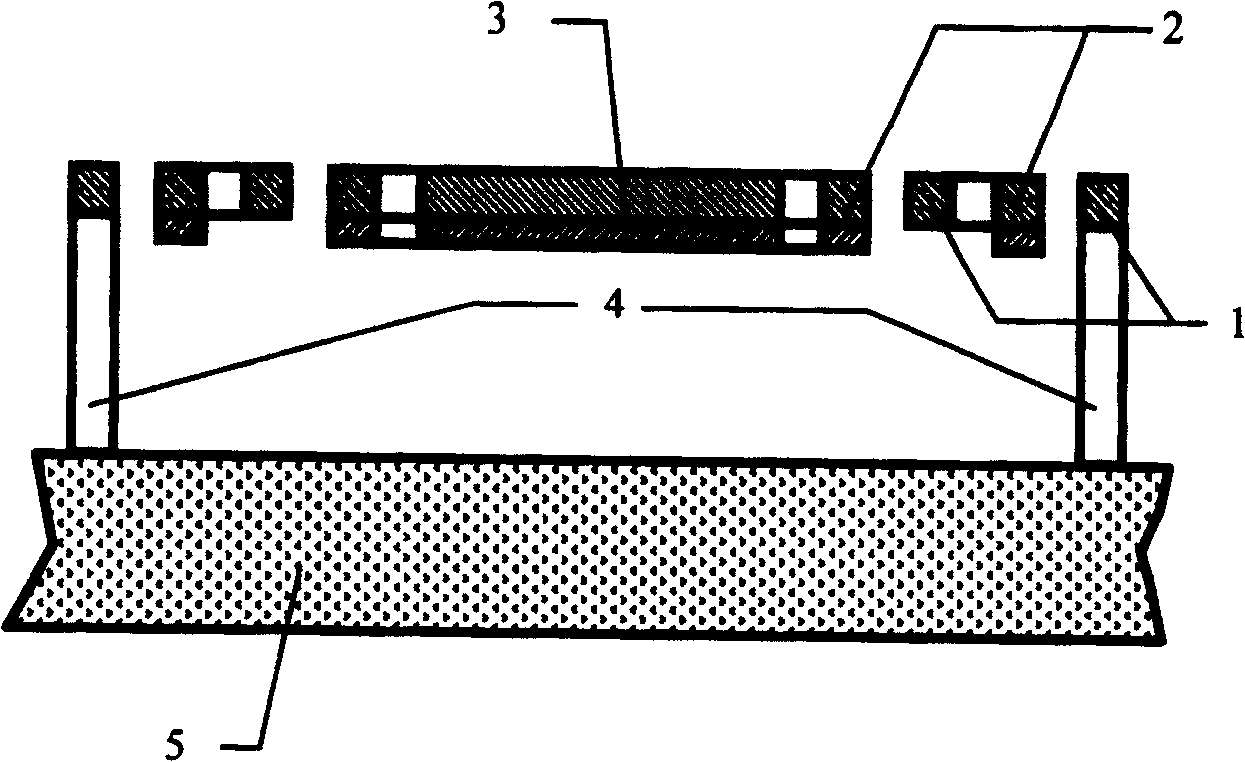

[0048] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a glass substrate 5 that is transparent to visible light but not infrared is adopted, and a microbeam unit 12 with a lateral support planar structure is arranged on the glass substrate 5; the microbeam unit 12 includes a thermal deformation mechanism and an infrared absorbing plate 3.

[0049] figure 2 As shown, there are two groups of thermal deformation mechanisms, which are symmetrically arranged on both sides of the infrared absorbing plate 3 , and each group of thermal deformation mechanisms consists of at least one thermal isolation beam 1 and at least one thermal deformation beam 2 to form a folding distribution.

[0050] image 3 As shown, the thermal deformation mechanism is connected to both sides of the infrared absorbing plate 3 with its inner end, and its outer final beam end is fixed on the glass substrate 5 in a standing form through the anchor foot 4 .

[0051] image 3 , Figure 4 ...

Embodiment 2

[0062] see Figure 12 , Figure 13 and Figure 14 What is different from the above-mentioned embodiment 1 is that in this embodiment, the infrared absorbing plate adopts a double-layer structure. are connected by reinforcing ribs 9, and the distance between them is , where λ is the peak value of the detected infrared wavelength, and n is a positive integer.

[0063] In specific implementation, the thickness of the lower reflective plate and the upper heat-absorbing resonant plate 8 is 0.3-3um, the thickness of the thermal isolation beam 1 and the thermal deformation beam 2 is 0.2-3um, and the distance between the micro-beam unit 12 and the glass substrate 5 is 2-3um. 7um.

[0064] In this structural form, the lower surface of the lower reflective plate is a reflective surface for optical readout detection, and the incident infrared rays are at the heat-absorbing resonant plate, that is, The antinode of the standing wave is formed at the place, so that the heat-absorbing...

Embodiment 3

[0066] see Figure 15 , Figure 16 and Figure 17 What is different from the above-mentioned embodiment 2 is that in this embodiment, on both sides of the upper heat-absorbing resonant plate 8, an eaves structure that improves the duty cycle of the heat-sensitive unit is extended, and the eaves just cover the area where the thermal deformation mechanism is located. . The eaves structure of the heat-absorbing resonant plate 8 can increase the duty cycle of the unit, thereby improving the absorption efficiency of infrared rays and improving the detection sensitivity.

[0067] In the above-mentioned embodiments, the infrared absorbing plate 3 is made of a thin film material that has a strong absorption effect on infrared rays, such as SiN x , SiO 2 , made of polysilicon, etc., the absorption area should be as large as possible to increase the heat absorbed. Moreover, in the sensitive direction of angular deflection, the optical detection sensitivity is directly proportional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com