High-strength, high-flexibility, water-proof and oil-proof cable

A water-proof, oil-proof, flexible technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problem of reducing the surface energy of the cable sheath, achieve good oxidation resistance, strong adhesion, and improve the effect of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

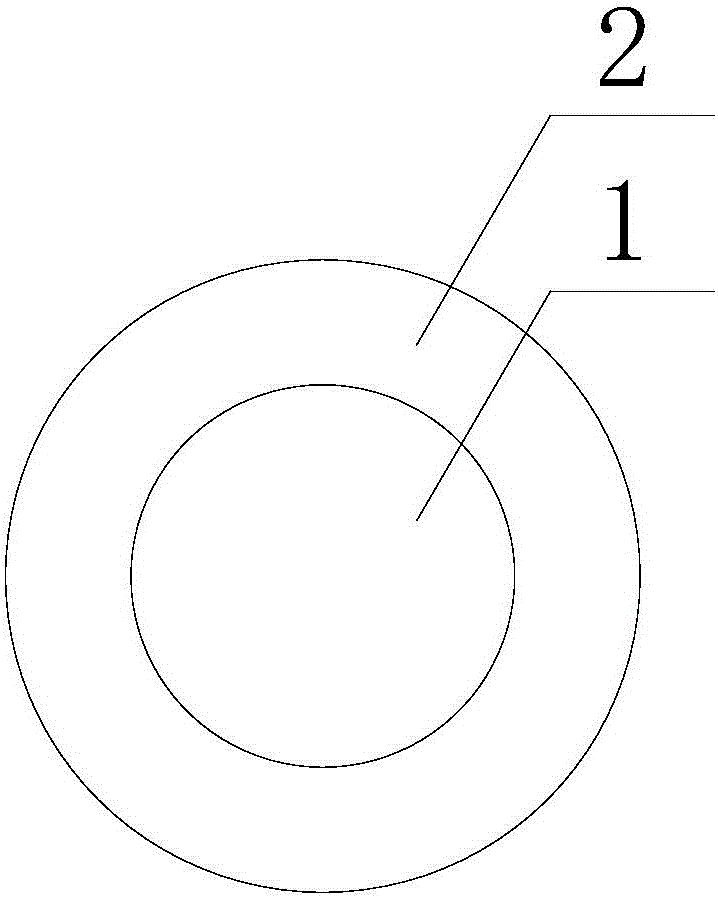

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a high-strength, high-flexibility waterproof and oil-proof cable proposed by the present invention.

[0016] refer to figure 1 , a high-strength, high-flexibility waterproof and oil-proof cable proposed by the present invention, comprising a cable core 1 and a sheath layer 2 coated on the outside of the cable core;

[0017] The raw materials of the sheath layer 2 include by weight: 35 parts of styrene-butadiene rubber, 26 parts of phenolic resin, 25 parts of fluorine-modified polyacrylate, 1.5 parts of dicumyl peroxide, 1 part of stearic acid, 1.8 parts of sulfur, 1.2 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 2 parts of antioxidant RD, 0.7 parts of bistriethoxytrisilane tetrasulfide, 7 parts of chlorinated paraffin, 25 parts of carbon black;

[0018] During the preparation of fluorine-modified polyacrylate, 25 parts of deionized water, 7 parts of perfluoroalkyl acrylate, 3.5 parts of...

Embodiment 2

[0020] A high-strength, high-flexibility waterproof and oil-proof cable proposed by the present invention includes a cable core 1 and a sheath layer 2 coated on the outside of the cable core;

[0021] The raw materials of the sheath layer 2 include by weight: 30 parts of styrene-butadiene rubber, 29 parts of phenolic resin, 22 parts of fluorine-modified polyacrylate, 1.8 parts of dicumyl peroxide, 0.7 parts of stearic acid, 2.2 parts of sulfur, 0.9 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 3 parts of antioxidant RD, 0.4 parts of bistriethoxytrisilane tetrasulfide, 10 parts of chlorinated paraffin, 22 parts of carbon black;

[0022] During the preparation of fluorine-modified polyacrylate, 28 parts of deionized water, 5 parts of perfluoroalkyl acrylate, 5 parts of silane coupling agent KH570, 6 parts of butyl acrylate, 6 parts of methyl methacrylate, 3 parts One part of lauryl methacrylate, 0.9 part of hydroxyethyl methacrylate, 0.4 part of potassium persulfate, 0.7 pa...

Embodiment 3

[0024] A high-strength, high-flexibility waterproof and oil-proof cable proposed by the present invention includes a cable core 1 and a sheath layer 2 coated on the outside of the cable core;

[0025] The raw materials of the sheath layer 2 include by weight: 33 parts of styrene-butadiene rubber, 27 parts of phenolic resin, 24 parts of fluorine-modified polyacrylate, 1.6 parts of dicumyl peroxide, 0.9 parts of stearic acid, 1.9 parts of sulfur, 1.1 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 2.2 parts of antioxidant RD, 0.6 parts of bistriethoxytrisilane tetrasulfide, 8 parts of chlorinated paraffin, 24 parts of carbon black;

[0026] During the preparation of fluorine-modified polyacrylate, 26 parts of deionized water, 6 parts of perfluoroalkyl acrylate, 3.8 parts of silane coupling agent KH570, 8 parts of butyl acrylate, 4 parts of methyl methacrylate, 5 parts Part of lauryl methacrylate, 0.7 part of hydroxyethyl methacrylate, 0.6 part of potassium persulfate, 0.55 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com