A Bubble Dispersion Method for the Preparation of Graphene/Epoxy Resin Composite Materials

An epoxy resin and graphene technology, applied in the field of nano-composite materials, can solve the problems of adverse effects on the mechanical properties of composite materials, affecting the effective range of ultrasonic waves, difficult to adapt to large-scale production needs, etc. Reasonable way and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

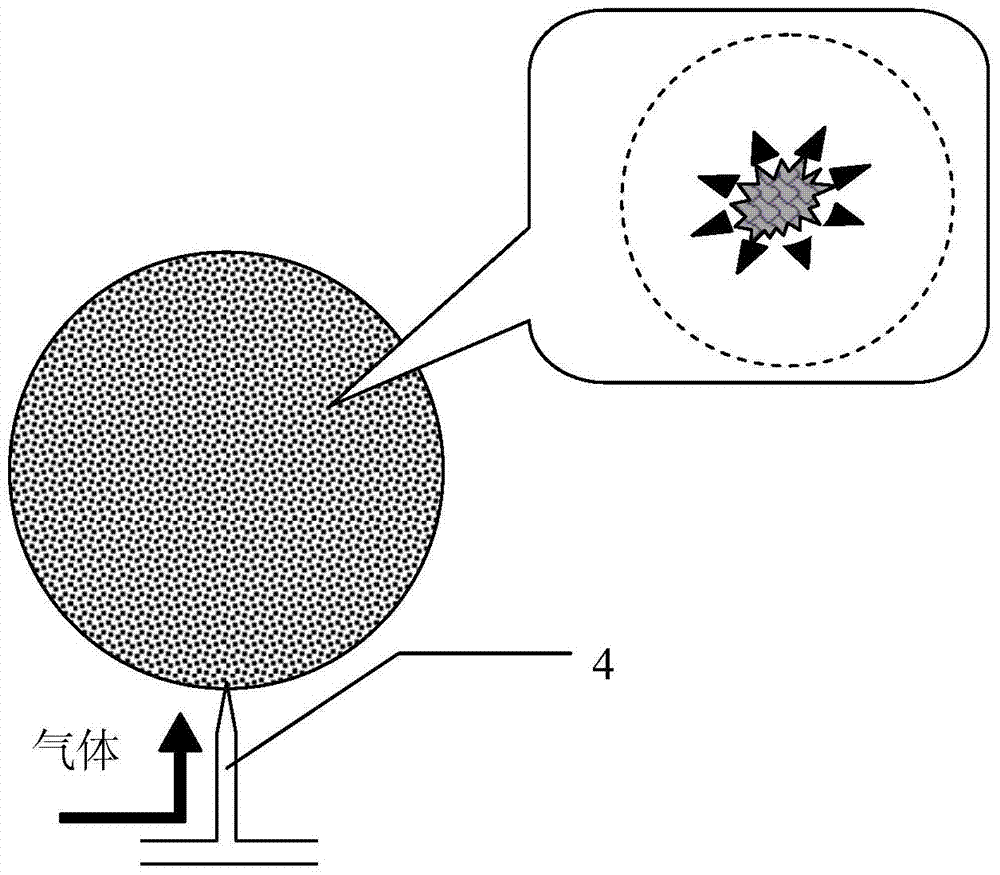

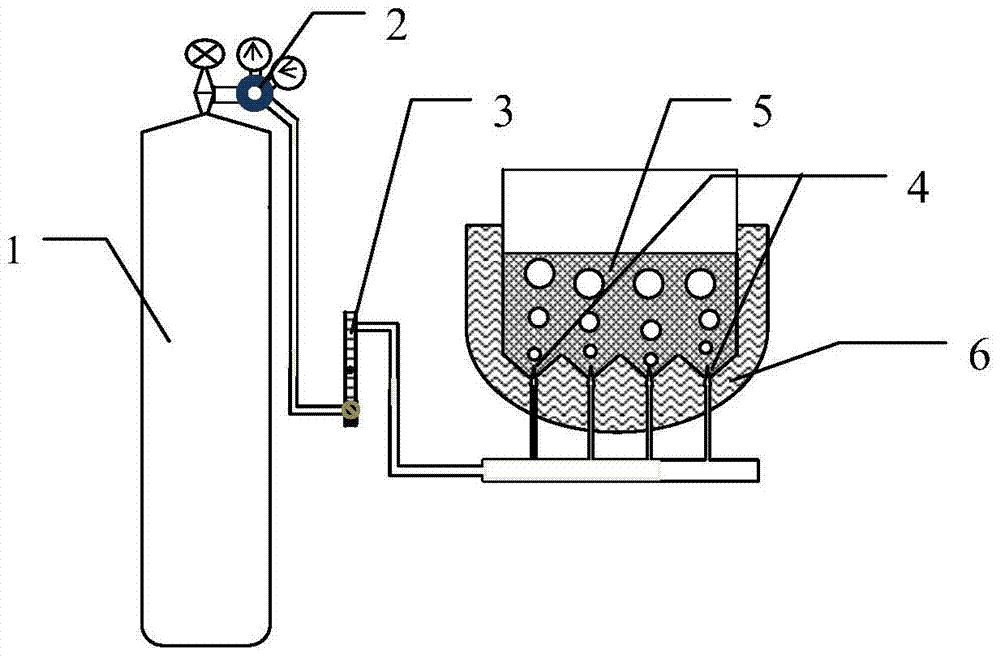

Embodiment 1

[0035] Weigh 100 parts of epoxy resin and 0.15 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 0.15%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 55°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 400mL / min / gas nozzle (the number of gas nozzles in this embodiment is 15) , each air nozzle has a flow rate of 400mL per minute, arranged in a honeycomb shape on the bottom of the sample pool, with a distance of 3cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersion device, to avoid local uneven dispersion , carry out bubbling for 6h; until bubbling for 5 hours and 50 minutes, take 10 parts of triethylenetetramine (10% of the mass of epoxy resin) and add to the sample pool, continue to bubbling to 4h; Put it in a vacuum drying oven at 80°C, perform vacuum defoa...

Embodiment 2

[0037] Weigh 100 parts of epoxy resin and 0.45 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 0.45%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 80°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 1000mL / min / gas nozzle (the number of gas nozzles in this embodiment is 20) , arranged in a honeycomb shape on the bottom surface of the sample pool, with a distance of 5 cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersion device, to avoid local uneven dispersion, bubbling for 2 hours; until bubbling for 1 hour 1 hour and 50 minutes, weigh 10 parts of triethylenetetramine (10% of the mass of the epoxy resin) and add it to the sample cell, and continue to aerate for 2 hours; After defoaming treatment for 1 hour, take it out, solidify and mold at room temperatur...

Embodiment 3

[0039] Weigh 100 parts of epoxy resin and 1.5 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 1.50%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 55°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 200mL / min / gas nozzle (the number of gas nozzles in this embodiment is 30) , arranged in a honeycomb shape on the bottom surface of the sample pool, with a distance of 4cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersing device, avoid local uneven dispersion, and bubble for 12 hours; until bubble 11 1 hour and 50 minutes, weigh 10 parts of triethylenetetramine (10% of the mass of epoxy resin) and add it to the sample cell, and continue to blow air for 12 hours; After 2 hours of defoaming treatment, take it out, solidify and mold at room temperature for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com