Inner cavity drilled multi-cutter machining device

A processing device and cutting tool technology, which is applied in the field of multi-tool processing devices for inner cavity drilling, can solve the problems of low processing efficiency, low production efficiency, and processing of parts with porous drilling machines, so as to improve processing efficiency, improve processing efficiency, The effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

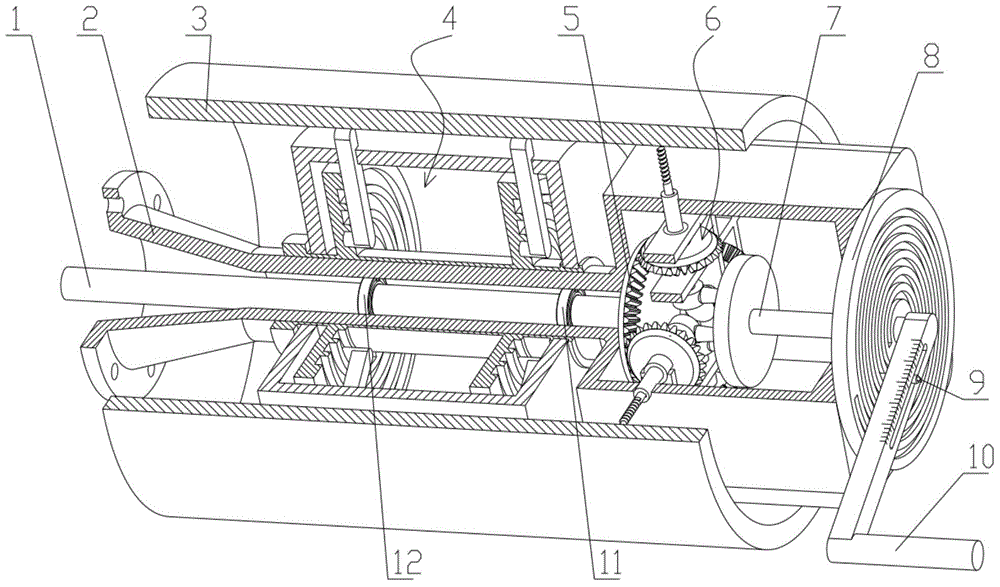

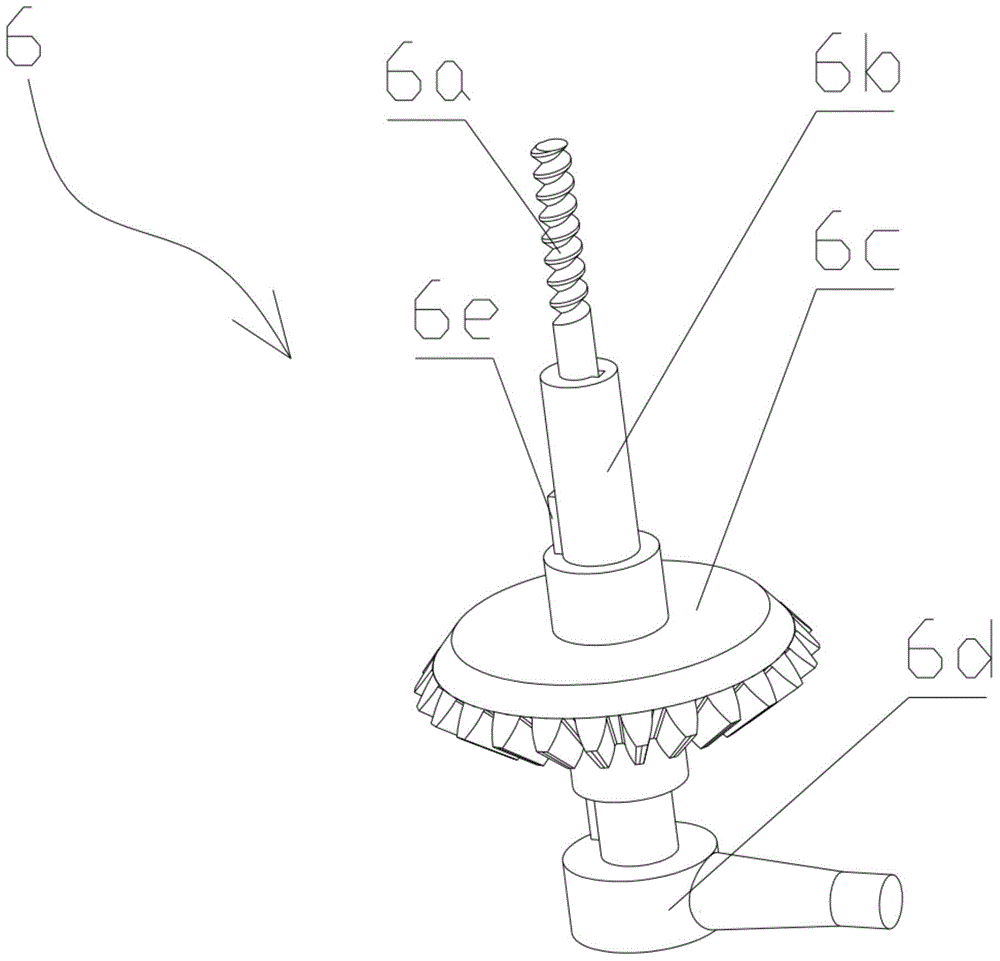

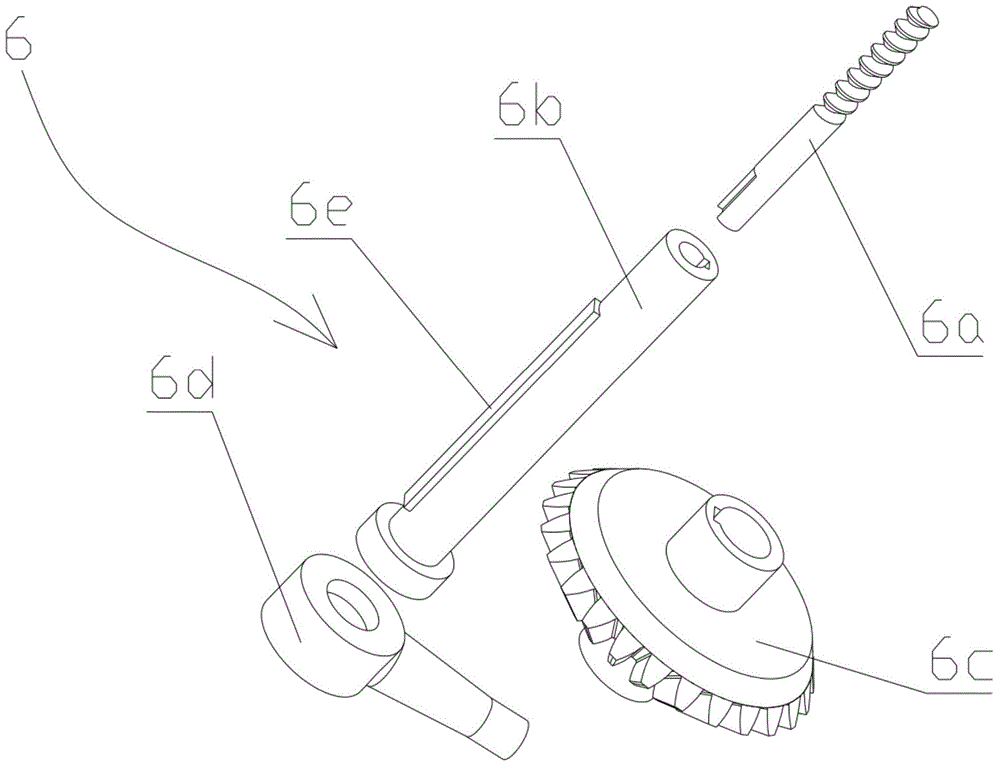

[0035] Such as figure 1 As shown, the present invention includes a tool mechanism 6, a transmission drive mechanism and a feed mechanism installed in the box body 2, and a support mechanism 4 that is connected between the outer wall of the box body 2 and the workpiece 3; the transmission drive mechanism connects the tool mechanism 6 to drive The tool rotates, and the feed mechanism is connected to the tool mechanism 6 to control its radial movement. The tool mechanism 6 includes multiple groups of tool assemblies uniformly distributed along the circumference, and each group of tool assemblies is radially installed and faces the inner wall of the workpiece 3, such as Figure 10 shown.

[0036] The transmission drive mechanism includes a main shaft 1 and a large bevel gear 5. The main shaft 1 is set in the central sleeve at one end of the box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com