Method for three-dimensional jet-printing, forming and casting of core

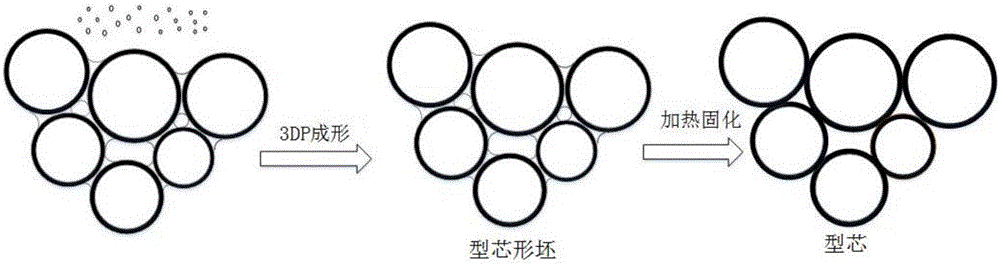

A casting mold, three-dimensional technology, used in casting molding equipment, cores, molds, etc., can solve the problem of layer-by-layer drying, and achieve the effect of increasing the effective bonding area, reducing internal stress, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Use the existing thermal coating process to prepare coated sand for 3DP. The coated sand has a particle size of 0.1mm to 0.2mm, including raw sand, novolac resin, calcium stearate and hexamethylenetetramine . Among them, the original sand is Baozhu sand, and the mass of phenolic resin is 2.2% of the original sand; the mass ratio of hexamethylenetetramine to phenolic resin is 8:100, and the mass ratio of calcium stearate to phenolic resin is 3:100.

[0037] (2) preparation is used to bond the bonding liquid of coated sand powder; The analytical pure dehydrated alcohol of 50g is joined in the container, then adds deionized water 49g (the mass ratio of deionized water and bonding liquid is 49: 100), polyethylene glycol 1g (mass ratio of polyethylene glycol to bonding liquid is 1:100), and made into bonding liquid.

[0038](3) Lay the coated sand into a thin layer with a thickness of 0.2 mm to 0.3 mm, and use a three-dimensional jet printing device to spray the bonding...

Embodiment 2

[0043] (1) Prepare the coated sand for 3DP by using the existing thermal coating process. The coated sand has a particle size of 0.1 mm to 0.25 mm, including raw sand, phenolic resin, calcium stearate and hexamethylenetetramine. Among them, the original sand is Baozhu sand, the content of phenolic resin is 2.4%, the curing agent urotropine is 2.2g, the mass ratio of hexamethylenetetramine to phenolic resin is 10:100, and the mass ratio of calcium stearate to phenolic resin is 10:100. The ratio is 5:100.

[0044] (2) prepare the bonding liquid that is used for bonding coated sand powder; The analytical pure dehydrated alcohol of 60g is joined in the container, then add deionized water 38.5g (the mass ratio of deionized water and bonding liquid is 38.5 :100), polyethylene glycol 1.5g (mass ratio of polyethylene glycol to bonding liquid is 1.5:100), was prepared into bonding liquid.

[0045] (3) The bonding liquid is deposited into the coated sand powder bed by 3DP forming equip...

Embodiment 3

[0049] (1) Prepare the coated sand for 3DP by using the existing thermal coating process, with a particle size of 0.1 mm to 0.25 mm, including raw sand, phenolic resin, calcium stearate and hexamethylenetetramine. Among them, the original sand is pearl sand, and the mass ratio of phenolic resin is 2.6% of the original sand; the mass ratio of hexamethylenetetramine to phenolic resin is 12:100, and the mass ratio of calcium stearate to phenolic resin is 7:100.

[0050] (2) preparation is used to bond the bonding liquid of coated sand powder; The analytical pure dehydrated alcohol of 75g is joined in the container, then adds deionized water 23g (the mass ratio of deionized water and bonding liquid is 23 : 100), polyethylene glycol 2g (mass ratio of polyethylene glycol to bonding liquid is 2: 100), prepared into bonding liquid.

[0051] (3) The bonding liquid is deposited into the coated sand powder bed by 3DP forming equipment, and the core-shaped blank is formed by layer-by-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com