Methylene blue temperature-sensitive hydrogel, preparation thereof, and application thereof in anatomical hepatectomies

A temperature-sensitive hydrogel and methylene blue technology, applied in the field of dyes, can solve the problems of affecting surgical operations, uneven dyeing, fast fading, etc., and achieve the effect of increasing specific surface area and good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

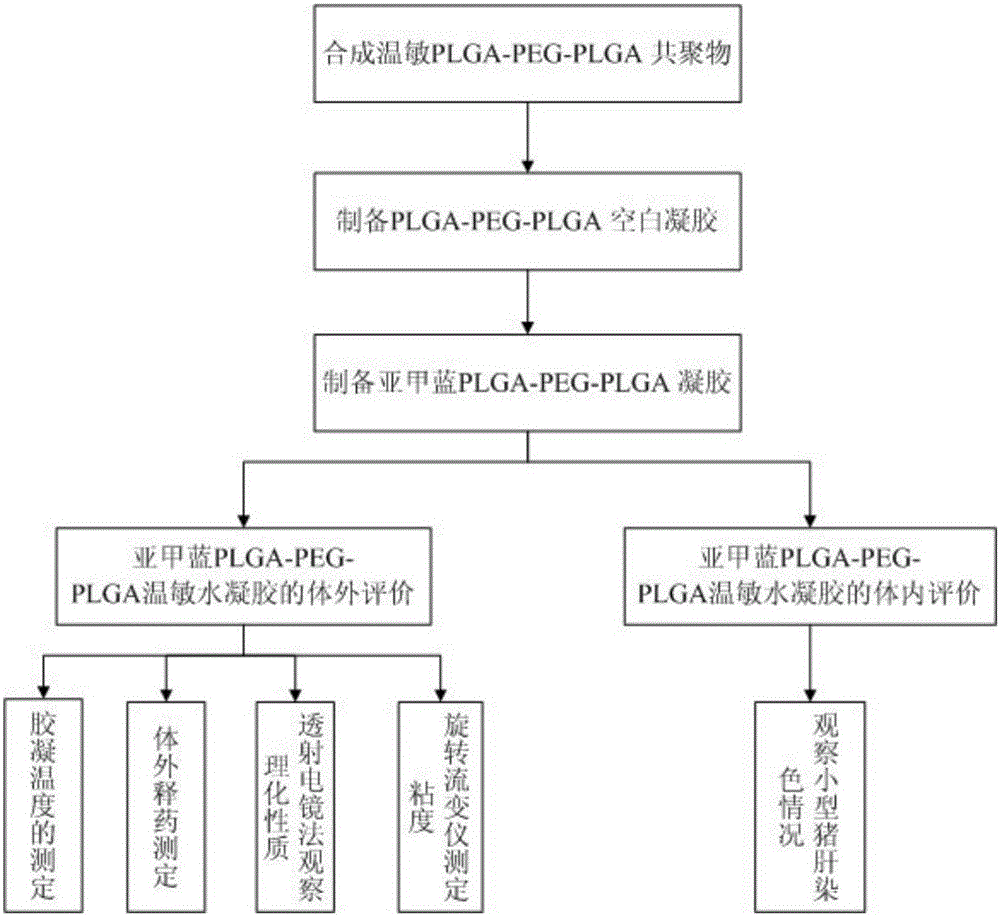

Method used

Image

Examples

preparation example Construction

[0028] 1) Preparation of copolymers: Weigh a certain amount of DL-LA, GA and PEG1500 and place them in an oven at 35-40°C for 1.5 hours, and then dry them at 120-140°C. Dry in the oven of ℃ for 0.5h, mix and pack in the dry 50mL vial after drying finishes, and add catalyzer stannous isooctanoate, the consumption of described catalyzer stannous isooctanoate is 0.2wt% of raw material gross mass, then put Place the vials into a freeze dryer for drying. The freeze drying temperature is -10 to -30°C, and the drying time is 1.5 to 2.0 hours. After vacuuming, the cap is taken out, and the cap is crimped and sealed with a penicillin bottle electric capping machine. React at 120-135°C for 13-14 hours, dissolve the obtained product in pure water at 5°C, heat to 75-80°C to precipitate the copolymer, discard the water layer, and repeat the operation 3 times to remove unreacted monomers and low molecular weight The water-soluble substance of the obtained copolymer is freeze-dried for 25-28...

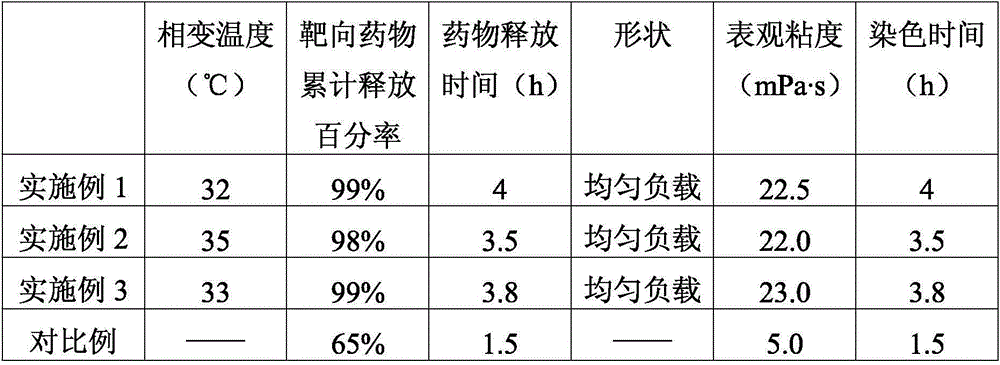

Embodiment 1

[0041] A methylene blue temperature-sensitive hydrogel, wherein the hydrogel is a temperature-sensitive polyglycolide-lactide-polyethylene glycol-polyglycolide-lactide gel loaded with methylene blue, and the methylene blue The weight-number ratio of the blue to the temperature-sensitive polyglycolide lactide-polyethylene glycol-polyglycolide lactide gel is 18:82.

[0042] The preparation method of the methylene blue thermosensitive hydrogel comprises steps:

[0043] 1) Preparation of copolymer: Weigh a certain amount of DL-LA, GA, and PEG1500 in an oven at 38°C for 1.5 hours, and then place them in an oven at 130°C Dry for 0.5h, mix and pack in the dry 50mL cillin bottle after drying, and add catalyst stannous isooctanoate, the consumption of described catalyzer stannous isooctanoate is 0.2wt% of raw material gross mass, then put the cillin bottle into Freeze drying machine for drying, freeze-drying temperature is -20°C, drying time is 2.0h, after being vacuumed, the cap is t...

Embodiment 2

[0048] A methylene blue temperature-sensitive hydrogel, wherein the hydrogel is a temperature-sensitive polyglycolide-lactide-polyethylene glycol-polyglycolide-lactide gel loaded with methylene blue, and the methylene blue The weight-number ratio of the blue to the temperature-sensitive polyglycolide lactide-polyethylene glycol-polyglycolide lactide gel is 15:85.

[0049] The preparation method of the methylene blue thermosensitive hydrogel comprises steps:

[0050] 1) Preparation of copolymer: Weigh a certain amount of DL-LA, GA, and PEG1500 in an oven at 40°C for 1.5 hours, and then place them in an oven at 140°C Dry for 0.5h, mix and pack in the dry 50mL cillin bottle after drying, and add catalyst stannous isooctanoate, the consumption of described catalyzer stannous isooctanoate is 0.2wt% of raw material gross mass, then put the cillin bottle into Freeze dryer for drying, freeze-drying temperature is -30°C, drying time is 1.5h, take out the cap after evacuation, use a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com