Health-care pumpkin seed beverage and processing method thereof

A technology for health-care beverages and pumpkin seeds, which is applied in food preparation, food science, application and other directions, can solve the problems of unsatisfactory emulsification effect, cumbersome process technology, and deterioration of beverage taste, saving peeling equipment, simple refining process, The effect of avoiding the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

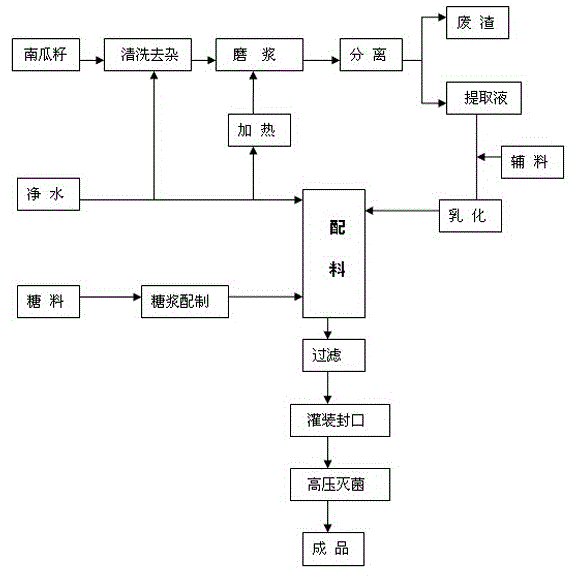

Image

Examples

Embodiment 1

[0040] Calculated by weight ratio, take 65 kg of dried pumpkin seeds, 30 kg of white sugar, 0.3 kg of sodium bicarbonate, 2.5 kg of mono- and diglyceride fatty acid esters, and 0.8 kg of sodium carboxymethyl cellulose.

[0041] Use the following steps to process pumpkin seed health drink:

[0042] 1. Cleaning: Take 65kg of dried pumpkin seeds according to the formula ratio, wash them with clean water, and remove mud, sand and other debris;

[0043] 2. Refining separation: mix the cleaned pumpkin seeds with 650kg of warm water at 65℃, grind it with a colloid, and then use the rotating speed of 2800r / min and the filter cloth density to be 300 mesh three-leg centrifugal separation to remove slag, and get 630kg pumpkin seeds Pulp

[0044] 3. Emulsification: Pump the separated pumpkin seed slurry into an emulsification tank, add 0.3 kg of sodium bicarbonate, 2.5 kg of mono- and diglyceride fatty acid esters, and 0.8 kg of sodium carboxymethyl cellulose. After stirring and dissolving, the m...

Embodiment 2

[0052] Calculated by weight ratio, take 60 kg of dried pumpkin seeds, 45 kg of white sugar, 0.1 kg of sodium carbonate, 3.5 kg of mono- and diglyceride fatty acid esters, and 1.2 kg of sodium carboxymethyl cellulose.

[0053] Use the following steps to process pumpkin seed health drink:

[0054] 1. Cleaning: Take 60kg of dried pumpkin seeds according to the formula ratio, wash them with clean water, and remove mud, sand and other debris;

[0055] 2. Refining separation: mix the cleaned pumpkin seeds with 600kg of warm water at 65℃, grind it with a colloid, and then use the rotating speed of 2800r / min and the filter cloth density to be 300 mesh three-leg centrifugal separation to remove slag to obtain 580kg pumpkin seeds. Pulp

[0056] 3. Emulsification: Pump the separated pumpkin seed slurry into an emulsification tank, add 0.1 kg of sodium carbonate, 3.5 kg of mono- and diglyceride fatty acid esters, and 1.2 kg of sodium carboxymethyl cellulose. After stirring and dissolving, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com