Starch induction type recombinant bacillus subtilis as well as preparation method and application thereof

A technology of Bacillus subtilis and amylase, applied in the fields of genetic engineering and enzyme engineering, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

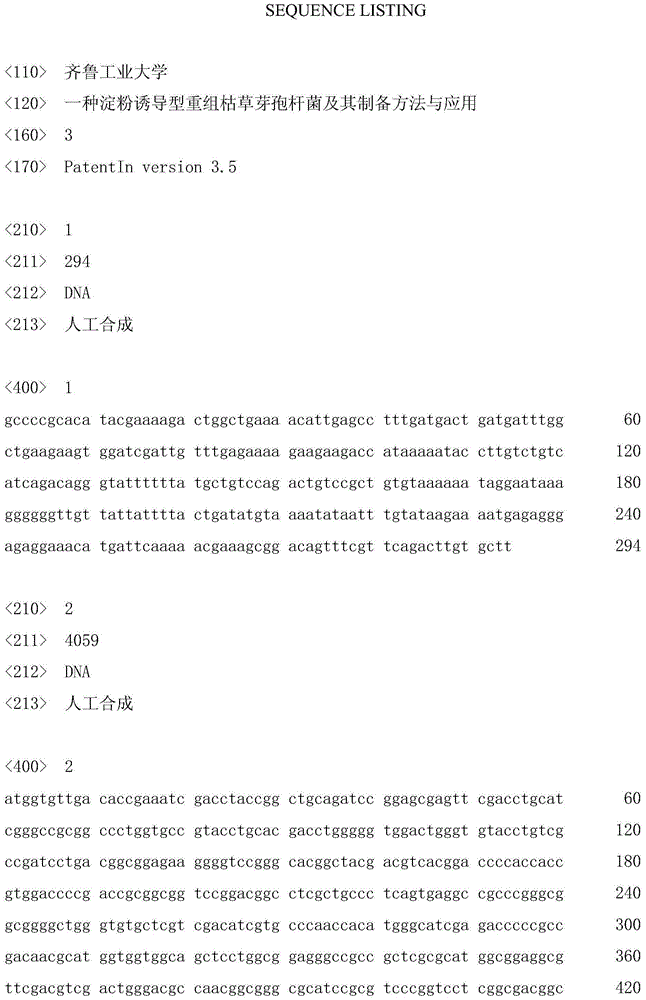

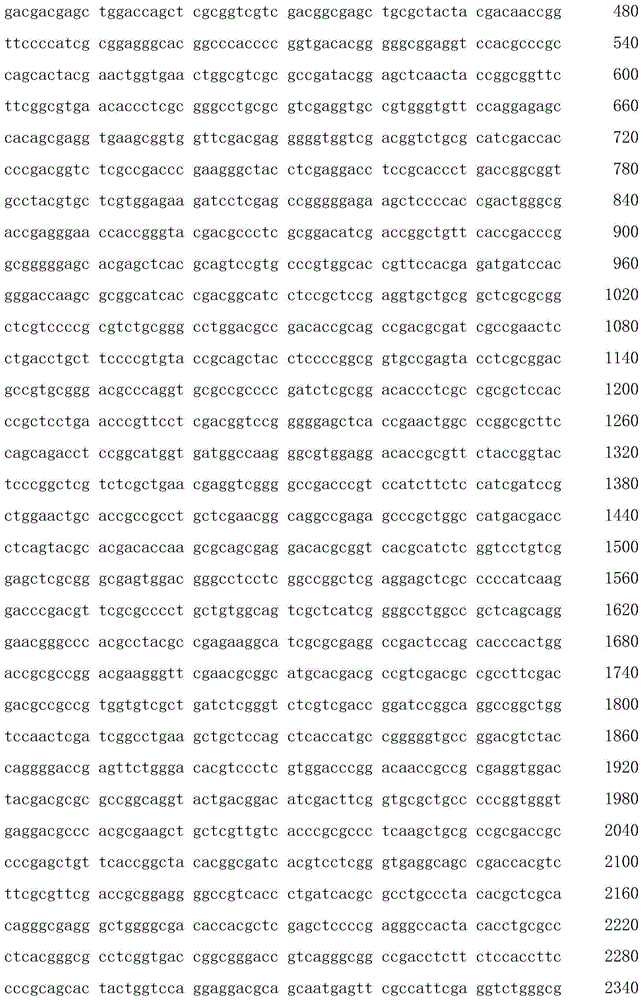

[0118] The α-amylase promoter PamyQ derived from Bacillus amyloliquefaciens (B.Amyloliquefaciens) was constructed into the shuttle plasmid PHT43 to replace the original Pgrac promoter;

[0119] Proceed as follows:

[0120] (i) using the shuttle plasmid PHT43 as a template to perform PCR amplification to obtain a PHT fragment;

[0121] Described PCR primer sequence is as follows:

[0122] PHT-up: 5'-ACTCAAACATCAAAATCTTACAAA-3'

[0123] PHT-down: 5'-CTTTTCGTATGTGCGGGGCGTGATAAGATAAAAAAATTTTTCACGCTTACATCAT-3'

[0124] The PCR amplification system is 50 μl:

[0125] 2×TaqPCR MasterMix 25 μl, primer PHT-up (10 μmol / L) 2.5 μl, primer PHT-down (10 μmol / L) 2.5 μl, template 2.5 μl, use ddH 2 O make up 50 μl;

[0126] The PCR amplification procedure is as follows:

[0127] Pre-denaturation at 95°C for 5min; denaturation at 95°C for 30sec, annealing at 51°C for 30sec, extension at 72°C for 40sec, 30 cycles; extension at 72°C for 10min, storage at -20°C;

[0128] (ii) extracting the...

Embodiment 2

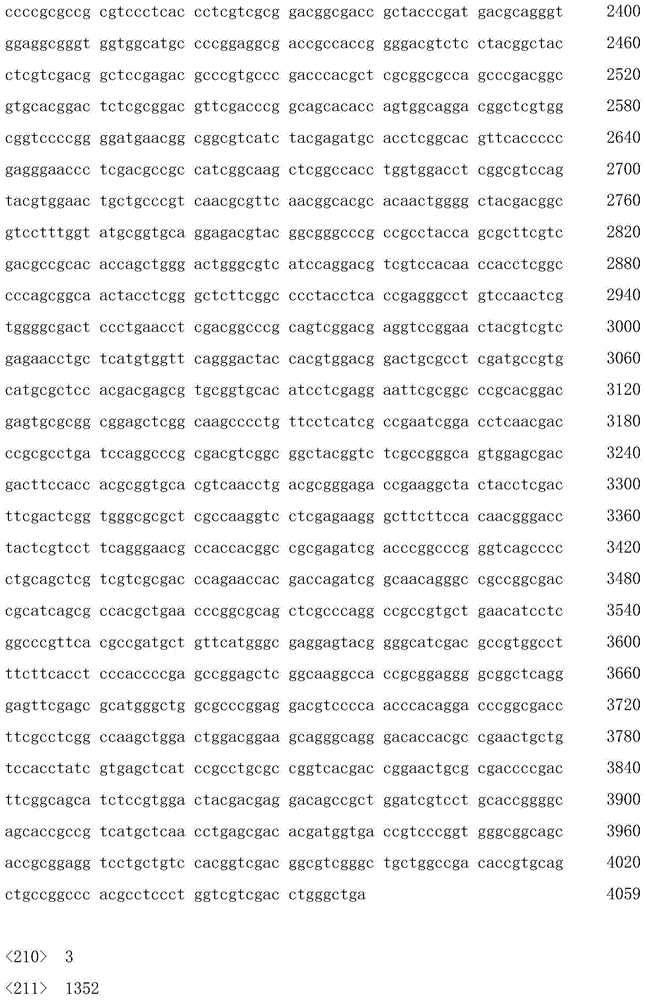

[0173] The maltooligosaccharide-based trehalose synthase gene derived from Arthrobacternicotinovorans was fused with the maltooligosaccharide-based trehalose hydrolase gene, and the fusion expression gene was constructed into the shuttle plasmid PHT43.

[0174] (viii) Using Arthrobacternicotinovorans genomic DNA as a template, respectively design primers F1 and R1 (amplification of maltooligosaccharide-based trehalose synthase TreY), F2 and R2 (amplification of maltooligosaccharide-based trehalose hydrolase TreZ);

[0175] F1: 5'-GGATCCGTGTTGACACCGAAATCGACCTACC-3'

[0176] R15'-CCTCGGGGGTGAACGTGC-3'

[0177] F2:5'-ATGAGTTCGCCATTCGAGGT-3'

[0178] R2: 5'-GACGTCGTCGAGCAGGTGGATGGAGG-3'

[0179] Using the Arthrobacternicotinovorans genome as a template and F1 and R1 as primers, the product TreY was obtained through the PCR process;

[0180] The PCR system is 50 μl:

[0181] 2×HiFi-PCRmaster25μl; Upstream primer F12.5μl; Downstream primer R12.5μl; Template 2.5μl; ddH 2 O 17.5 ...

Embodiment 3

[0200] Transformation of the recombinant shuttle plasmid PamyQ-PHT43-TreY-TreZ in Bacillus subtilis WB800n;

[0201] A single colony of Bacillus subtilis WB800n was picked and inoculated in TBY medium (1% tryptone, 0.5% yeast extract, 1% NaCl), and cultivated overnight in a 37°C incubator.

[0202] Use 100mL LBSP medium (tryptone 10g / L, yeast extract 5g / L, NaCl 1g / L, glucose 250mmol / L, K 2 HPO 4 / KH 2 PO 4 50mmol / L, pH7.2) to dilute 2mL of the overnight culture, cultivate at 37°C and 220rpm until the OD value is 1.0; place the bacterial solution on ice for 10min; centrifuge at 10000rpm for 5min in a cold centrifuge tube at 4°C to enrich cells;

[0203] SHMG (sucrose 250mmol, Hepes1mmol, MgCl 2 0.5 mmol, glycerol 10%) to wash the enriched cells three times, and finally dissolve in 3 mL of ice-bathed SHMG; aliquot competent cells in 100 μl each, and store at -80°C.

[0204] Take a tube of competent cells and quickly place them in 37°C water until they dissolve; take 1-10 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com