Preparation method of reactive carbon nanotube flame retardant

A carbon nanotube and flame retardant technology, which is applied in the field of preparation of reactive carbon nanotube flame retardants, can solve problems such as the inability to improve the flame retardant performance of a composite system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

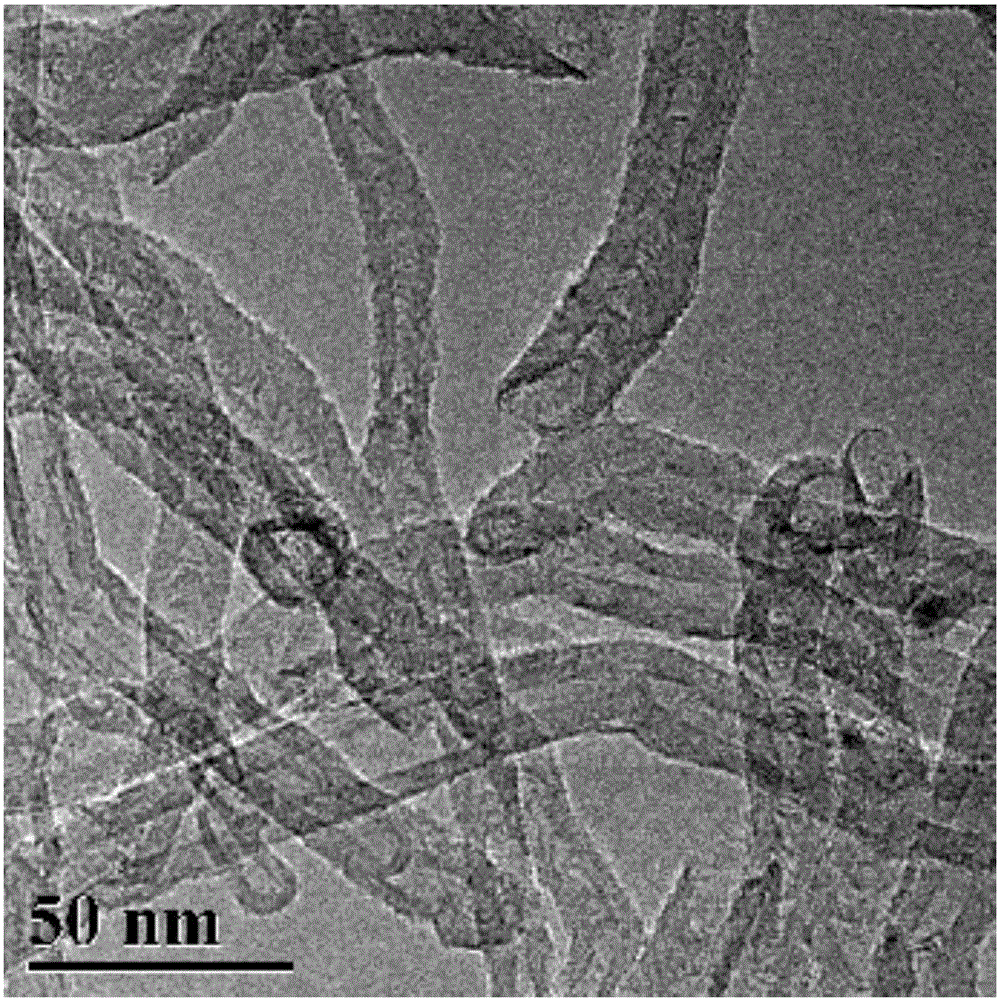

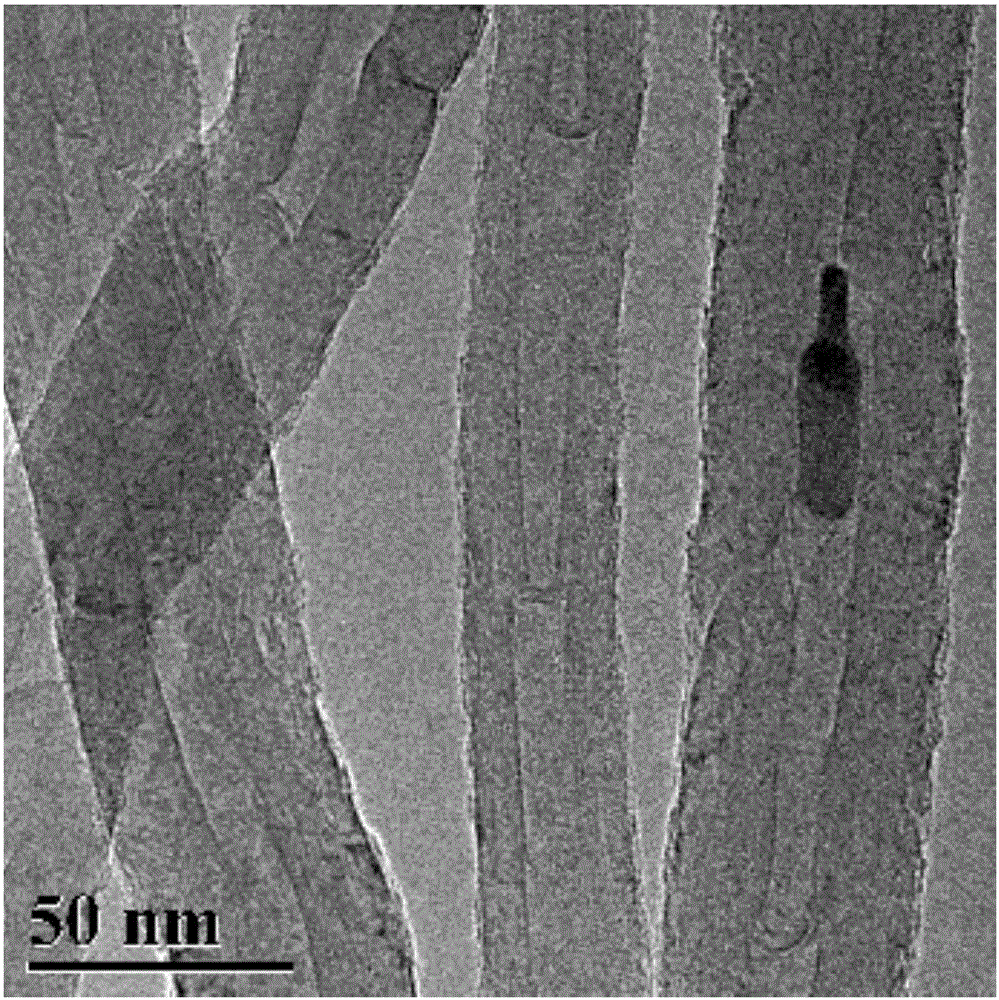

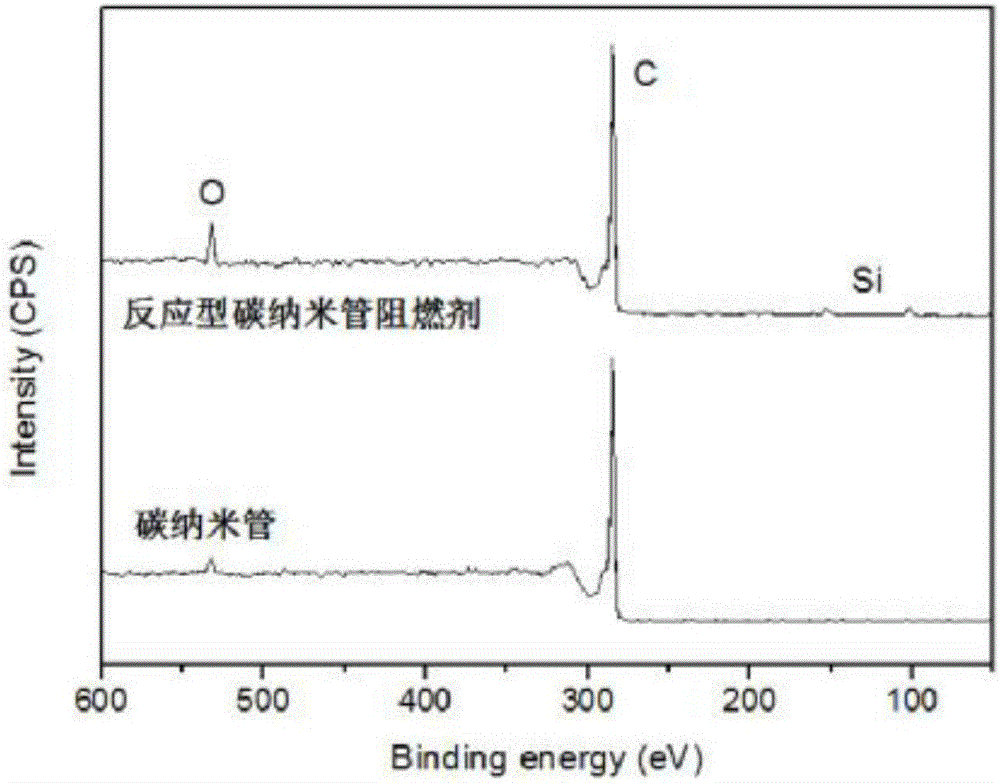

Image

Examples

Embodiment 1

[0028] The preparation method of reactive carbon nanotube flame retardant in the present embodiment comprises the following steps:

[0029] (1) Preparation of polysiloxane

[0030] Measure 15mL of ethanol and 5mL of deionized water, add 0.2g of aminopropyltriethoxysilane, 0.2g of vinyltrimethoxysilane, and 2g of phenyltrimethoxysilane, and stir well; slowly add four Methylammonium hydroxide, control the pH value of the reaction solution to 8, stir and react at room temperature for 4h; after the reaction is completed, collect the product through a rotary evaporator, and finally dry it in vacuum at room temperature to obtain polysilicon containing amino, vinyl, and phenyl Oxygen;

[0031] (2) Preparation of reactive carbon nanotube flame retardant

[0032] Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF, and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solution, and react for 24 hours under...

Embodiment 2

[0037] The preparation method of reactive carbon nanotube flame retardant in the present embodiment comprises the following steps:

[0038] (1) Preparation of polysiloxane

[0039] Measure 30mL of ethanol and 10mL of deionized water, add 0.5g of aminopropyltrimethoxysilane, 0.2g of vinylmethyldimethoxysilane, and 1g of phenyltrimethoxysilane, and stir well; Add tetraethylammonium hydroxide, control the pH value of the reaction solution to 10, and stir the reaction at room temperature for 6 hours; after the reaction is completed, the product is collected by a rotary evaporator, and finally vacuum-dried at room temperature to obtain amino, vinyl, and phenyl compounds. Polysiloxane;

[0040] (2) Preparation of reactive carbon nanotube flame retardant

[0041]Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solution, and react for 30 h under mag...

Embodiment 3

[0044] The preparation method of reactive carbon nanotube flame retardant in the present embodiment comprises the following steps:

[0045] (1) Preparation of polysiloxane

[0046] Measure 30mL of ethanol and 10mL of deionized water, add 0.5g of aminopropyltrimethoxysilane, 0.2g of vinylmethyldimethoxysilane, and 1g of phenyltrimethoxysilane, and stir well; Add tetrabutylammonium hydroxide, control the pH value of the reaction solution to 10, and stir the reaction at room temperature for 6 hours; after the reaction is completed, collect the product through a rotary evaporator, and finally dry it in vacuum at room temperature to obtain polysilicon containing amino groups, vinyl groups, and phenyl groups. Oxygen;

[0047] (2) Preparation of reactive carbon nanotube flame retardant

[0048] Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com