Method for preparing aromatic aldehyde compounds from sodium lignosulfonate

A technology of sodium lignosulfonate and aromatic aldehydes, which is applied in the oxidation preparation of carbonyl compounds, the preparation of organic compounds, the separation/purification of carbonyl compounds, etc., and can solve the problems of harsh reaction conditions, high reaction temperature, and high requirements for enzyme culture conditions, etc. problems, to achieve the effect of environmental protection in the preparation process, mild reaction conditions, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

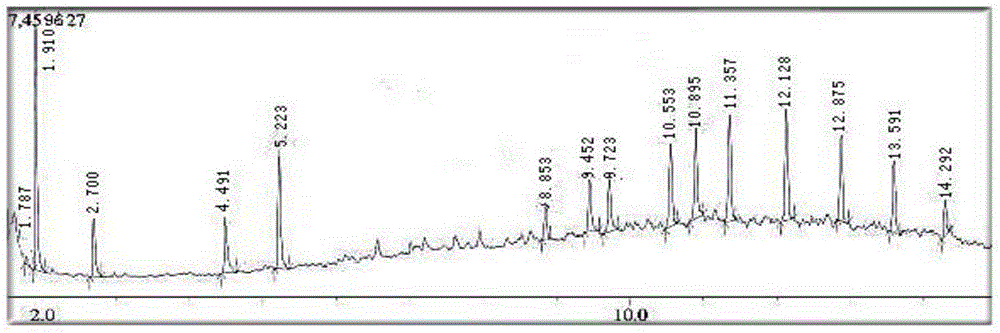

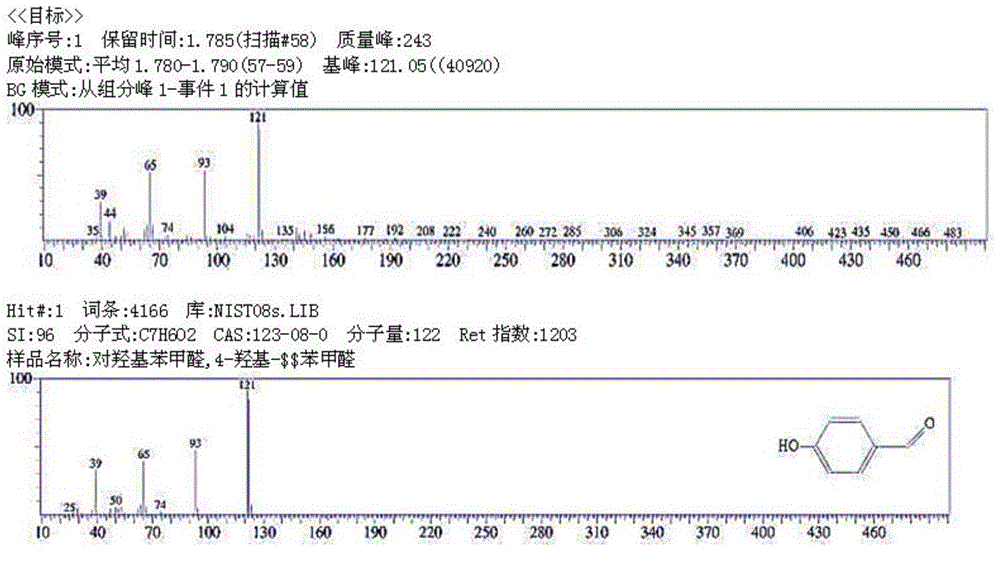

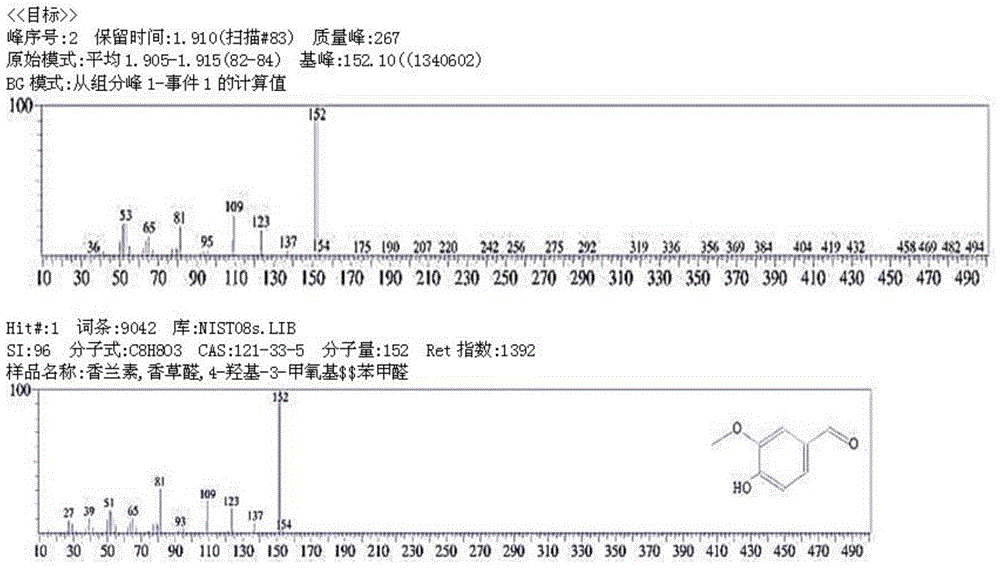

Image

Examples

Embodiment 1

[0028] A method utilizing sodium lignosulfonate to prepare aromatic aldehyde compounds, specifically comprising the following steps:

[0029] (1) Add sodium hydroxide to deionized water, and mix well to obtain an aqueous sodium hydroxide solution with a concentration of 5% by mass;

[0030] Take 140ml of sodium hydroxide aqueous solution with a mass percentage concentration of 5%, then add 7.0g of sodium lignosulfonate, stir for 5-15min, and maintain the temperature at 5-10°C to obtain system 1;

[0031] The amount of sodium lignosulfonate is calculated by mass ratio, sodium lignosulfonate: the concentration of 5% sodium hydroxide aqueous solution is 1g: 20ml;

[0032] (2) Under stirring conditions, add 9.0ml of oxidant dropwise to system 1, add 1.0g of catalyst at the same time, control the temperature at 5-10°C for 2.0h, and obtain a reaction solution;

[0033] The oxidizing agent used is a hydrogen peroxide solution with a mass percentage concentration of 30%, sodium ligno...

Embodiment 2

[0051] A method utilizing sodium lignosulfonate to prepare aromatic aldehyde compounds, specifically comprising the following steps:

[0052] (1) Add sodium hydroxide to deionized water and mix well to obtain an aqueous solution of sodium hydroxide with a concentration of 2% by mass;

[0053] Take 30ml of sodium hydroxide aqueous solution with a mass percentage concentration of 2%, then add 1.0g of sodium lignosulfonate, stir for 5-15min, and maintain the temperature at 35-40°C to obtain system 1;

[0054] The amount of sodium lignosulfonate is calculated by mass ratio, sodium lignosulfonate: the concentration of 2% alkaline aqueous solution is 1.0g: 30ml;

[0055] (2) Under stirring conditions, add 2.5ml of oxidant dropwise to system 1, add 0.10g of catalyst at the same time, control the temperature at 35-40°C for 1.5h, and obtain a reaction solution;

[0056] The oxidizing agent used is a hydrogen peroxide solution with a mass percentage concentration of 30%, sodium lignosu...

Embodiment 3

[0062] A method utilizing sodium lignosulfonate to prepare aromatic aldehyde compounds, specifically comprising the following steps:

[0063] (1) Add sodium hydroxide to deionized water and mix well to obtain an aqueous solution of sodium hydroxide with a concentration of 4% by mass;

[0064] Take 30ml of sodium hydroxide aqueous solution with a mass percentage concentration of 4%, then add 1.0g of sodium lignosulfonate, stir for 5-15min, and maintain the temperature at 55-60°C to obtain system 1;

[0065] The amount of sodium lignosulfonate is calculated by mass ratio, sodium lignosulfonate: the alkaline aqueous solution with a mass percentage concentration of 4% is 1g: 30ml;

[0066] (2) Under stirring conditions, add 2ml of oxidant dropwise to system 1, add 0.05g of catalyst at the same time, control the temperature at 55-60°C for 1.0h, and obtain the reaction solution;

[0067] The oxidizing agent used is a hydrogen peroxide solution with a mass percentage concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com