A preparation method of lithium ferrite thermal spraying powder for conductive coating

A technology of lithium ferrite and conductive coating is applied in the field of preparation of lithium ferrite thermal spray powder for conductive coating, and can solve the problem that the conductive performance of lithium ferrite coating cannot meet the electrical performance requirements of grounding materials and the like , to achieve the effect of simple and controllable process and equipment, short production cycle and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of lithium ferrite thermal spray powder for conductive coating, the method comprising the following steps:

[0038] 1) Mixing and shaking: Li 2 CO 3 (99.9% pure) and Fe 2 o 3 (Purity is 99.9%) The powder is dried at 150°C for 3 hours to remove moisture, mixed in a double-stirring mixer with a molar ratio of 1:5, and stirred for 1 hour; the mixed powder is put into a vibrating crusher, Vibrate for 2 minutes under the oscillation condition of frequency and amplitude of 15mm to compact the powder;

[0039]2) Pelletizing and drying: After wetting the raw material powder obtained in step 1) with deionized water as the medium, manually make small balls with a diameter of 5-10mm; then place the obtained small spherical raw material powder in an electric blast In a drying oven, dry at 150°C for 6 hours to fully remove the moisture brought in during the ball forming process;

[0040] 3) Calcination and crushing: put the small spherical powder obtained i...

Embodiment 2

[0046] A preparation method of lithium ferrite thermal spray powder for conductive coating, the method comprising the following steps:

[0047] 1) Mixing and shaking: Li 2 CO 3 (99.9% pure) and Fe 2 o 3 (Purity is 99.9%) The powder is dried at 150°C for 3 hours to remove moisture, mixed in a double-stirring mixer at a molar ratio of 1:5, and stirred for 1.5 hours; the mixed powder is put into a vibrating crusher, and Vibrate for 3 minutes under the vibration condition of 50Hz frequency and 12mm amplitude to compact the powder;

[0048] 2) Pelletizing and drying: After wetting the raw material powder obtained in step 1) with deionized water as the medium, manually make small balls with a diameter of 5-10mm; then place the obtained small spherical raw material powder in an electric blast In a drying oven, dry at 150°C for 7 hours to fully remove the moisture brought in during the ball forming process;

[0049] 3) Calcination and crushing: put the small spherical powder obta...

Embodiment 3

[0055] A preparation method of lithium ferrite thermal spray powder for conductive coating, the method comprising the following steps:

[0056] 1) Mixing and shaking: Li 2 CO 3 (99.9% pure) and Fe 2 o 3 (Purity is 99.9%) The powder is dried at 150°C for 3 hours to remove moisture, mixed in a double mixer mixer at a molar ratio of 1:5, and stirred for 2 hours; the mixed powder is put into a vibrating crusher, Vibrate for 4 minutes under the oscillation condition of frequency and amplitude of 10mm to compact the powder;

[0057] 2) Pelletizing and drying: After wetting the raw material powder obtained in step 1) with deionized water as the medium, manually make small balls with a diameter of 5-10mm; then place the obtained small spherical raw material powder in an electric blast In a drying oven, dry at 150°C for 8 hours to fully remove the moisture brought in during the ball forming process;

[0058] 3) Calcination and crushing: put the small spherical powder obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

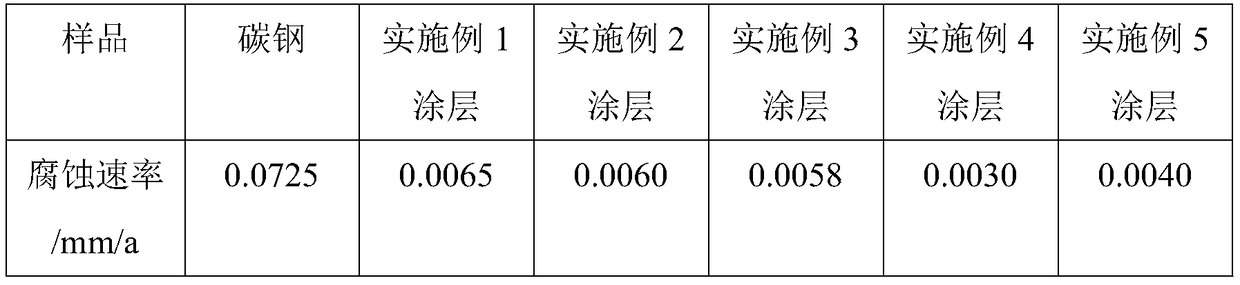

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com