Fired mold precision casting method for improving solidification heat dissipation conditions of directional solidification casting

A technology of investment precision casting and directional solidification, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problem of optimization of the structure and performance of castings with high temperature gradients that cannot guarantee the solidification interface of castings, and cannot fundamentally improve castings. Solidification interface temperature gradient, poor thermal conductivity of mold shell materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

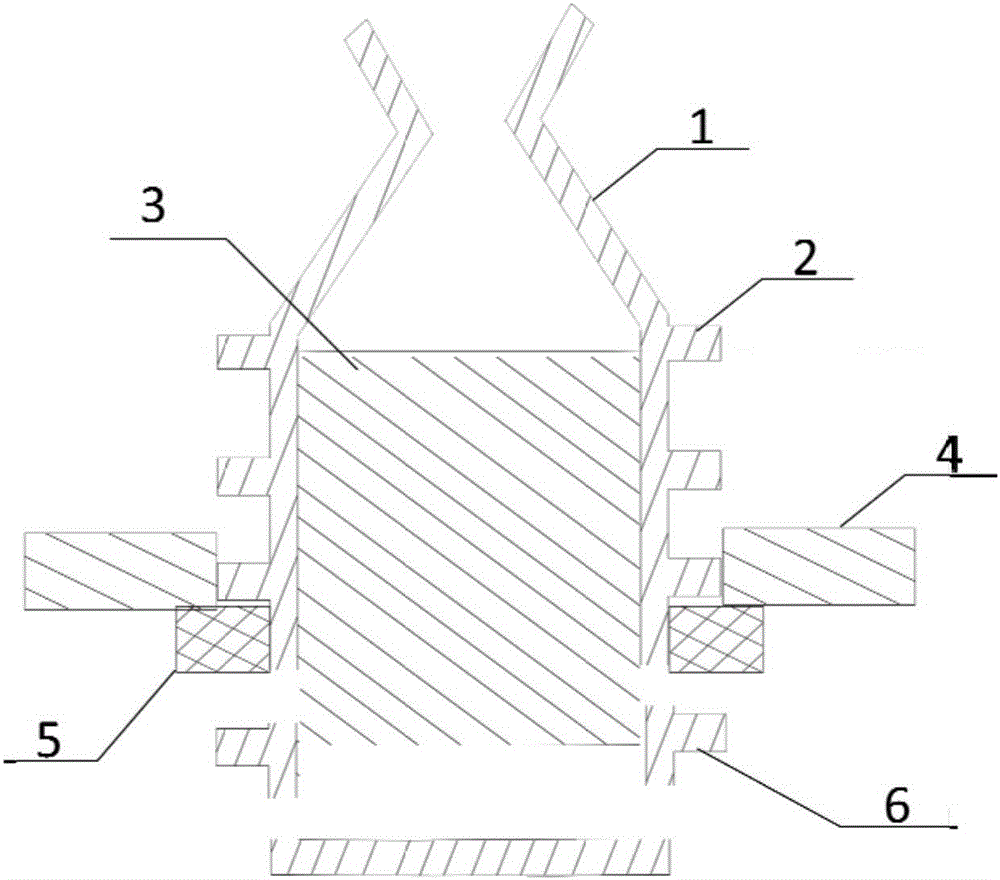

Image

Examples

Embodiment 1

[0020] Embodiment 1, the improvement of the current directional solidification method only improves the condition of heat dissipation from the surface of the mold shell to the surrounding environment, and does not fundamentally change the huge thermal resistance brought by the mold shell itself during the solidification process of the casting, so it is difficult to fundamentally improve the quality of the casting. The temperature gradient at the solidification interface. For this reason, this embodiment adopts an investment casting method that improves the solidification and heat dissipation conditions of directional solidification castings, and the specific steps are as follows:

[0021] Step 1: Prepare a wax mold of the specifications required by the casting according to the conventional method, and manufacture the inner cavity of the mold shell.

[0022] Step 2: Make the surface layer and the back layer of the formwork according to material requirements.

[0023] Step 3: P...

Embodiment 2

[0027] Embodiment 2, the specific steps of this embodiment are as follows:

[0028] Step 1: Prepare a wax mold of the specifications required by the casting according to the conventional method, and manufacture the inner cavity of the mold shell.

[0029] Step 2: Make the surface layer and the back layer of the formwork according to material requirements.

[0030] Step 3: Prepare equidistant rectangular grooves with an interval of 8 mm on the outer surface of the formwork, and then perform firing strengthening.

[0031] Step 4: Install a mechanical expansion device that matches the equidistant rectangular groove in step 3 immediately below the heat shield of the directional solidification furnace, that is, the mechanical expansion device can be embedded in the equidistant rectangular groove.

[0032] Step 5: Install the qualified groove-shaped formwork into the directional solidification furnace, pour alloy liquid into the formwork, and move the formwork to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com