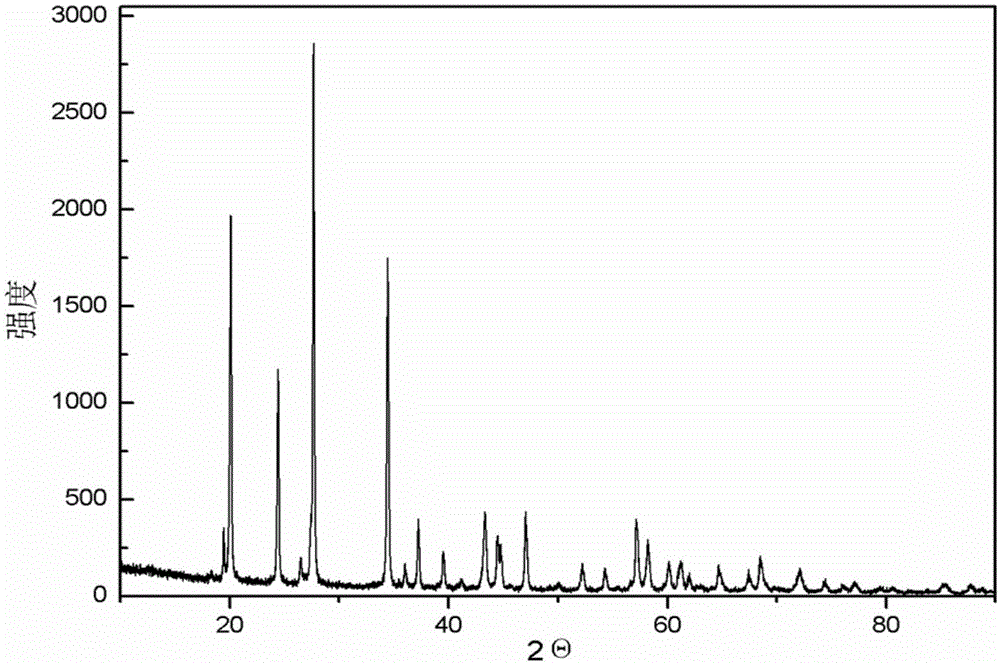

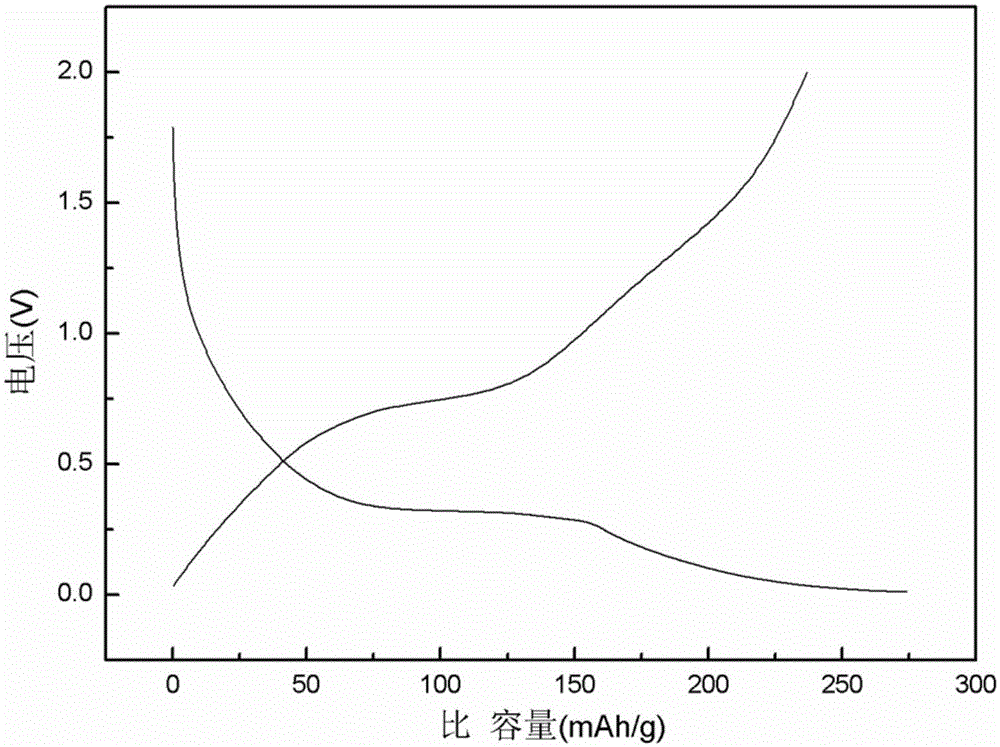

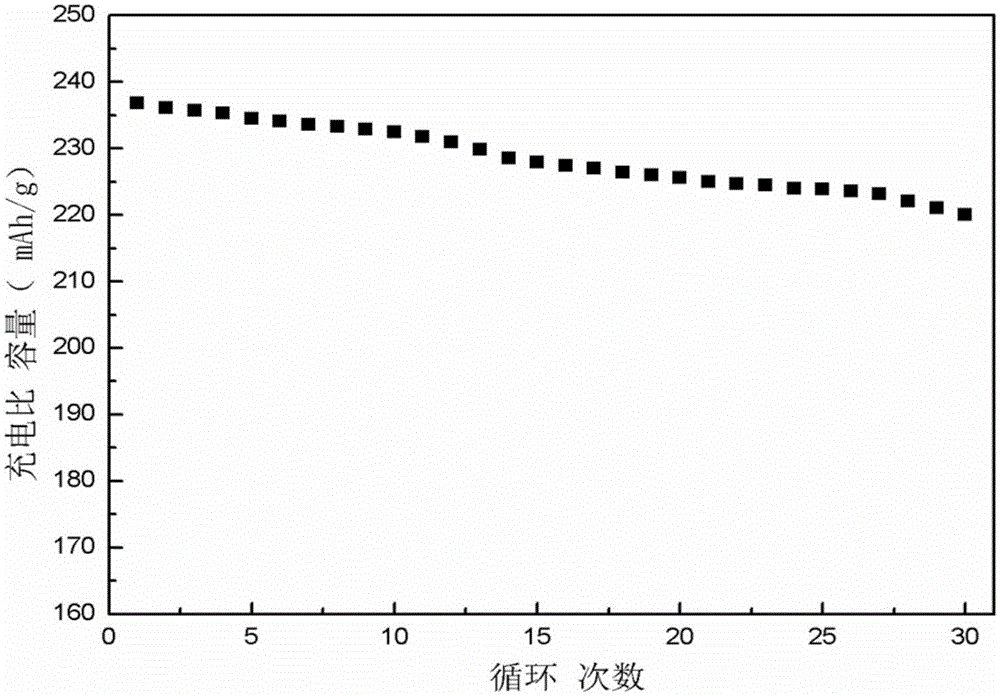

Preparation method of lithium titanium silicate anode material for lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of lithium-ion battery operating voltage reduction, cycle performance degradation, high charge and discharge platform, etc., to achieve good electrochemical performance Performance, low cost, and the effect of improving energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of titanium silicate lithium lithium ion battery negative electrode material of the present invention, comprises the following steps:

[0030] 1) Take by weighing 2.4960g of lithium chloride, 5.5853g of silicon tetrachloride and 5.0017g of titanium tetrachloride, after being dissolved in 15ml of absolute ethanol respectively, mix the three together, and stir evenly to obtain mixture.

[0031] 2) Add hydrochloric acid to the mixed solution under constant stirring to adjust the pH value of the system to 5.5.

[0032] 3) The mixed solution after step 2) was transferred into a three-necked flask, and then water vapor at 100° C. was carried by nitrogen gas and then passed into the mixed solution at a rate of 0.5 L / min for hydrolysis reaction to obtain a white coprecipitate. Suction filtration was performed with a vacuum filter, and the obtained coprecipitate was repeatedly washed 3 times with deionized water. Transfer the washed co-precipitate into an ...

Embodiment 2

[0037] A preparation method of titanium silicate lithium lithium ion battery negative electrode material of the present invention, comprises the following steps:

[0038] 1) Weigh 5.0969g of lithium acetate, 8.1790g of tetrabutyl titanate and 5.0533g of tetraethyl orthosilicate, respectively dissolve them in 15ml of absolute ethanol, then mix the three together and stir evenly , to obtain a mixed solution.

[0039] 2) Add glacial acetic acid to the mixed solution under constant stirring to adjust the pH value of the system to 3.5.

[0040] 3) The mixed solution after step 2) was transferred into a three-necked flask, and then water vapor at 120° C. was passed into the mixed solution at a rate of 1.0 L / min through nitrogen gas to carry out hydrolysis reaction to obtain a white coprecipitate. Suction filtration was performed with a vacuum filter, and the obtained coprecipitate was repeatedly washed 3 times with deionized water. Transfer the washed co-precipitate into an oven a...

Embodiment 3

[0044] A preparation method of titanium silicate lithium lithium ion battery negative electrode material of the present invention, comprises the following steps:

[0045] 1) Weigh 4.5206g of lithium oxalate, 6.6941g of titanium tetraisopropoxide and 4.1995g of methyl triethoxy silicon, dissolve them in 15ml of absolute ethanol respectively, mix the three together, and stir Evenly, a mixed solution was obtained.

[0046] 2) Add oxalic acid to the mixed solution under constant stirring to adjust the pH value of the system to 2.5.

[0047] 3) The mixed solution after step 2) was transferred into a three-necked flask, and then water vapor at 150° C. was passed into the mixed solution at a rate of 1.5 L / min through nitrogen carrier flow to carry out hydrolysis reaction to obtain a white coprecipitate. Suction filtration was performed with a vacuum filter, and the obtained coprecipitate was repeatedly washed 3 times with deionized water. Transfer the washed co-precipitate into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com