Activated metal electrode based on oxygen-metal battery

A technology of metal batteries and activated metals, which is applied to the electrodes of primary batteries, fuel cell half-cells and primary battery half-cells, etc. It can solve the problems of high infrastructure dependence, unsuitable for excessive discharge, and scarce raw materials, etc., to achieve Effect of reducing corrosion and high concentration, reducing negative electrode polarization, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

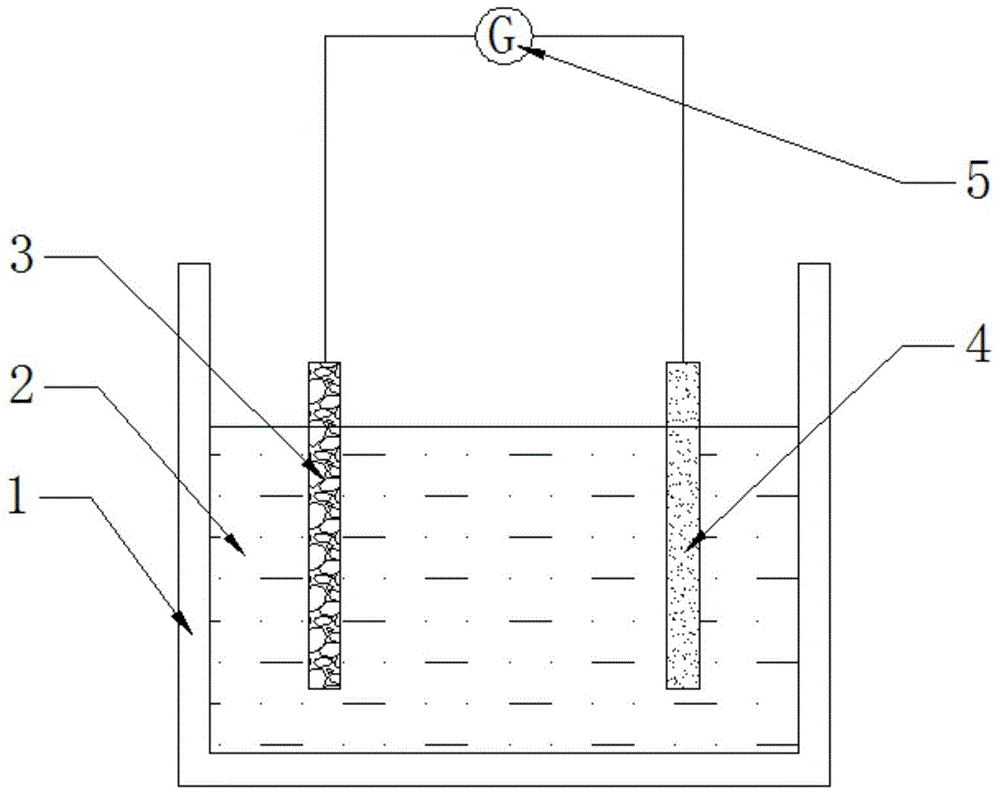

Image

Examples

Embodiment 1

[0026] Embodiment 1: Add B element to the activation of Fe

[0027] In this embodiment, the selected added element is B, and the nominal composition is determined to be Fe: B=1:1 (atomic ratio), that is, Fe 50 B 50 , the implementation method is as follows:

[0028] ● Preparation:

[0029] Step 1: Ingredients

[0030] Press Fe 50 B 50 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0031] Step 2: Smelting

[0032] Put the weighed Fe and B elements into the quartz tube, cover the lid, and melt in a vacuum high-frequency induction melting furnace;

[0033] The melting conditions are: the vacuum degree in the vacuum high-frequency induction melting furnace during melting is 8×10 -3 Pa below, filled with 0.5Mpa high-purity argon, smelting for 5-10 minutes.

[0034] Step Three: Spray Casting

[0035] Put the master alloy obtained in step 2 into a vacuum induction metal melt rapid cooling solidifica...

Embodiment 2

[0046] Example 2: Activation of Al by adding Si element

[0047] In this embodiment, the selected additive element is Si, and the nominal composition is determined to be Al:Si=9:1 (atomic ratio), that is, Al 90 Si 10 , the implementation method is as follows:

[0048] ● Preparation:

[0049] Step 1: Ingredients

[0050] Press Al 90 Si 10 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0051] Step 2: Smelting

[0052] Put the weighed Al and Si elements into the copper crucible of the true high arc melting furnace, put Si inside the Al, and melt for 3-4 times.

[0053] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt for 3-4 times.

[0054] Step Three: Spray Casting

[0055] Put the master alloy obtained in step 2 into a vacuum induction metal melt q...

Embodiment 3

[0066] Embodiment 3: the activation effect of adding C element to Ti

[0067] In the present embodiment, the selected added element is C, and the nominal composition is determined to be Ti:C=72:28 (atomic ratio), and the implementation method is as follows:

[0068] ● Preparation:

[0069] Step 1: Ingredients

[0070] Press Ti 72 C 28 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0071] Step 2: Smelting

[0072] Put the weighed Ti and C elements into the copper crucible of the true high arc melting furnace, put C on the top of Ti, and melt for 3-4 times.

[0073] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill it with 0.5Mpa high-purity argon, and melt it under 300A current, 1-2 minutes for each melting, and 3-4 times of melting. After the smelting is completed, use a copper crucible with high-pressure cooling water to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com