Phosvitin phosphopeptide enrichment method

A technology of phosvitin and phosphopeptide, which is applied in the field of extraction, purification and separation, can solve the problems of poor stability of magnetic nanoparticles, large amount of organic reagents, complicated operation, etc., and achieves short separation and purification cycle, high adsorption efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: egg yolk protein powder partial dephosphorization method

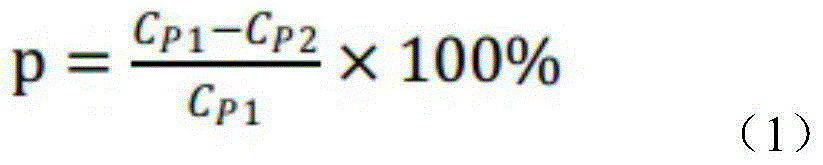

[0053] Egg yolk protein powder is placed in NaOH solutions of different concentrations of 0.05-0.2mol / L, stirred at 37°C for 3 hours to carry out alkaline dephosphorization treatment, and the treated solution is subjected to ultrafiltration to remove phosphate ions (ultrafiltration membrane is 3000K, the return port pressure is 5-10psi, and the inlet pressure is 20-30psi), the dephosphorization rate of egg yolk protein powder treated with different concentrations of NaOH solution was compared.

[0054] The result shows that 0.05mol / LNaOH, dephosphorization rate is 27%; 0.1mol / LNaOH, dephosphorization rate is 46%; when 0.15mol / L, dephosphorization rate is 53%; %.

Embodiment 2

[0055] Example 2: Enzymolysis of partially dephosphorylated egg yolk protein powder

[0056] Enzymatic hydrolysis of partially dephosphorylated egg yolk protein powder found that the dephosphorization rate was low, resulting in a low degree of hydrolysis. However, if the dephosphorylation is excessive, the calcium-storing function of the resulting PPPs is reduced. Therefore, the dephosphorized egg yolk protein powder with a dephosphorization rate of 46%-64% is selected for enzymatic hydrolysis.

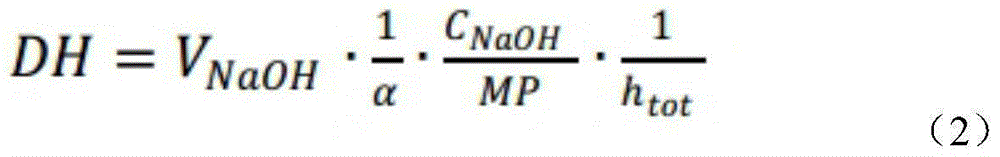

[0057] The enzymolysis process is as follows: add dephosphorylated egg yolk protein powder and deionized water into the enzymolysis reactor (substrate concentration is 1%), heat in a water bath at 50°C, and adjust the pH to 8.0 after the solution is evenly stirred. The trypsin was added to the above solution (enzyme:substrate=5:100), titrated with 0.1mol / L NaOH solution during the reaction to maintain the pH at 8.0, and the reaction time was 4h. After the enzymolysis, the above reac...

Embodiment 3

[0058] Example 3: Mesoporous / Macroporous TiO 2 material preparation

[0059] Convenient and rapid synthesis of mesoporous / macroporous TiO by sol-gel method using tetra-n-butyl titanate as titanium source 2 Material.

[0060] The specific experimental method is as follows: First, weigh 0.3g of citric acid, dissolve it in 40mL of 95% absolute ethanol, add 18mL of ammonia solution after magnetic stirring for 30min, continue stirring for 10min, and then take 5mL of tetra-n-butyl titanate , under stirring, the above solution was added dropwise, and after magnetic stirring for 1 h, it was left to stand at room temperature for 12 h. Then, the precipitate was washed successively with distilled water and absolute ethanol, and the washed material was dried in a drying oven at 60° C. for 14 h. Finally, the above materials were calcined in a temperature-programmed muffle furnace at 550° C. for 4 h.

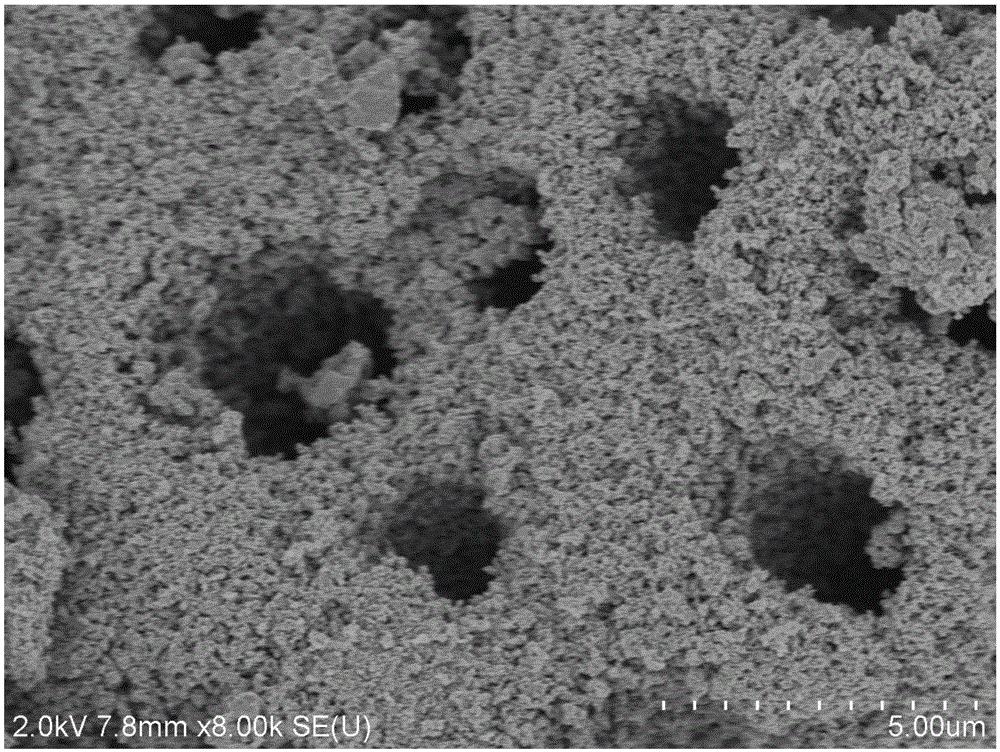

[0061] The resulting mesoporous / macroporous TiO 2 The scanning electron microscope i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com