High-performance water-based jet ink for polyethylene and preparation method of high-performance water-based jet ink

A high-performance, polyethylene technology, applied in the field of coatings, can solve the problem of inability to use PE products, and achieve the effects of not easy to fade, fade and fall off, good adhesion, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

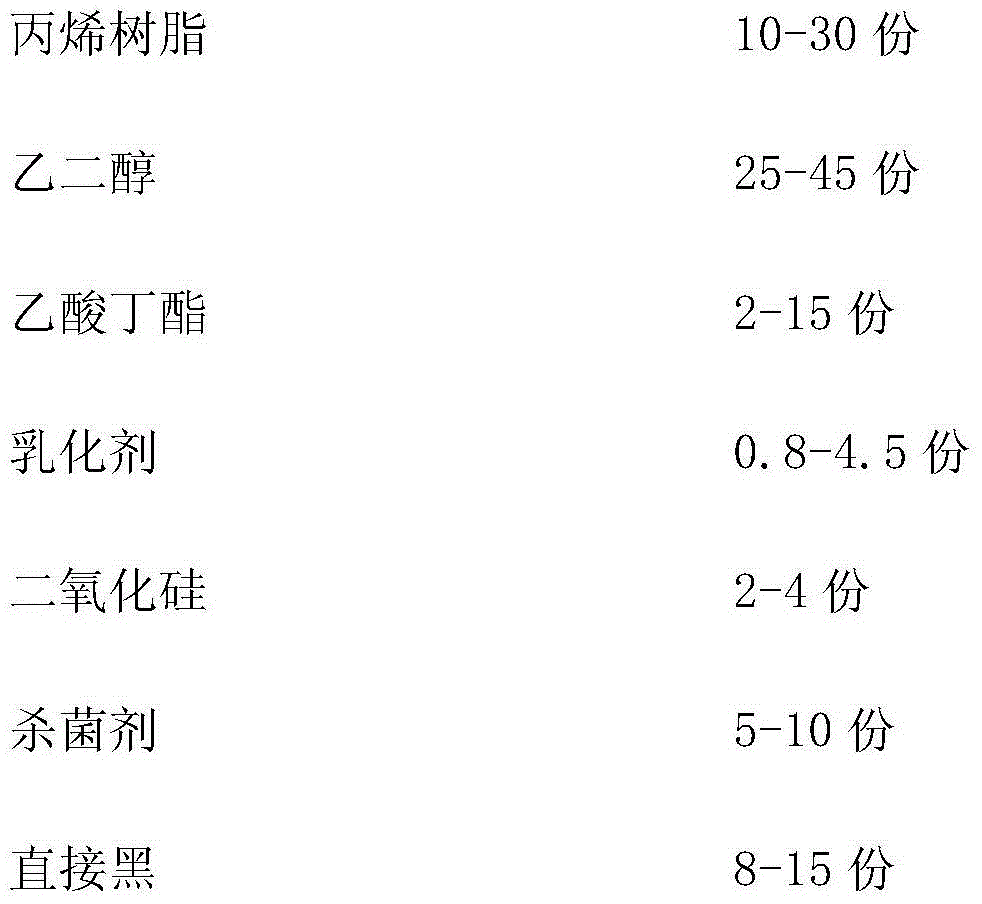

[0042] This embodiment provides a high-performance water-based inkjet ink for polyethylene, the composition of which is calculated in parts by mass as follows:

[0043]

[0044] Among them, the propylene resin is a modified chlorinated polypropylene resin, the emulsifier is a mixture of 45% polyoxyethylene sorbitan monolaurate and 55% polyoxyethylene bis-sorbitan monolaurate, silicon dioxide For hydrophilic fumed silica.

[0045] This embodiment also provides a method for preparing a high-performance water-based inkjet ink for polyethylene. The specific preparation steps are as follows:

[0046] Step (1): Place a three-necked flask with an electric stirrer at room temperature, and dissolve the propylene resin in butyl acetate with a solid content of 20%;

[0047] Step (2): Disperse the emulsifier in 30% ionized water, then slowly drop it into the flask in step (1) under constant stirring at a rotating speed of 2600r / min for emulsification, continue stirring for 18h and then stand stil...

Embodiment 2

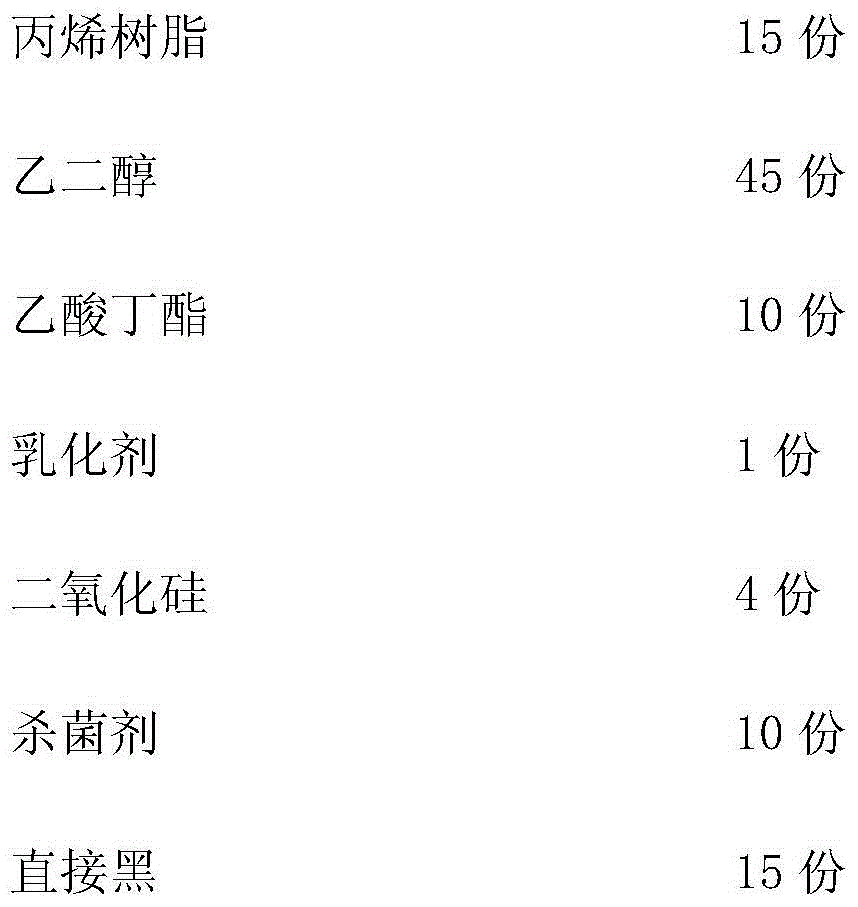

[0052] This embodiment provides a high-performance water-based inkjet ink for polyethylene, the composition of which is calculated in parts by mass as follows:

[0053]

[0054] Among them, the propylene resin is a modified chlorinated polypropylene resin, the emulsifier is a mixture of 75% polyoxyethylene sorbitan monolaurate and 25% polyoxyethylene sorbitan monolaurate, silicon dioxide For hydrophilic fumed silica.

[0055] This embodiment also provides a method for preparing a high-performance water-based inkjet ink for polyethylene. The specific preparation steps are as follows:

[0056] Step (1): Place a three-necked flask with an electric stirrer at room temperature, and dissolve the propylene resin in butyl acetate with a solid content of 20%;

[0057] Step (2): Disperse the emulsifier in 36% ionized water, then slowly drop it into the flask in step (1) under constant stirring at a rotating speed of 2600r / min for emulsification, continue stirring for 15 hours and then stand sti...

Embodiment 3

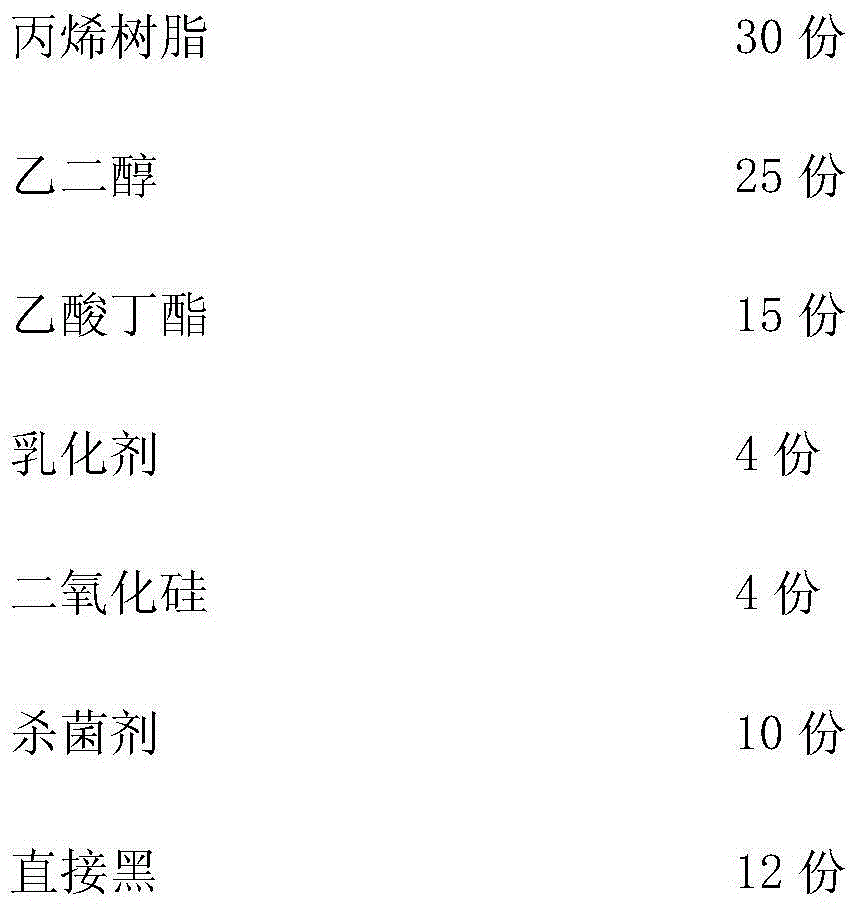

[0062] This embodiment provides a high-performance water-based inkjet ink for polyethylene, the composition of which is calculated in parts by mass as follows:

[0063]

[0064] Among them, the propylene resin is a modified chlorinated polypropylene resin, the emulsifier is a mixture of 60% polyoxyethylene sorbitan monolaurate and 40% polyoxyethylene bis-sorbitan monolaurate, silicon dioxide For hydrophilic fumed silica.

[0065] This embodiment also provides a method for preparing a high-performance water-based inkjet ink for polyethylene. The specific preparation steps are as follows:

[0066] Step (1): Place a three-necked flask with an electric stirrer at room temperature, and dissolve the propylene resin in butyl acetate with a solid content of 20%;

[0067] Step (2): Disperse the emulsifier in 44% ionized water, then slowly drop it into the flask in step (1) under constant stirring at a rotating speed of 2600r / min for emulsification, continue stirring for 10 hours and then stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com