Preparation method of low-fluorine silicone rubber used for ceramic composite insulator

A technology of porcelain composite insulators and fluorosilicone rubber, which is applied in the field of rubber to achieve the effects of excellent high and low temperature resistance, good aging resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 6 parts of precipitated white carbon black, 18 parts of flame retardant, 3 parts of zinc stearate, 2 parts of activated magnesium oxide, and 2 parts of iron oxide powder in a double-roller Mix uniformly in the kneader to obtain a uniform masterbatch, wherein the linear speed of the front roller of the two-roll kneader is 25m / min, and the speed ratio of the front and rear rollers is 1:1.3; the flame retardant is aluminum hydroxide Compounding with antimony trioxide, the compounding molar ratio of aluminum hydroxide and antimony trioxide is 1:1, the masterbatch is kneaded in a kneader at 170°C and a vacuum of -0.09MPa for 10min, and then added 0.1 part of dicumyl peroxide was mixed again at 200° C. for 3 hours, and left overnight to prepare the low-fluorine silicone rubber.

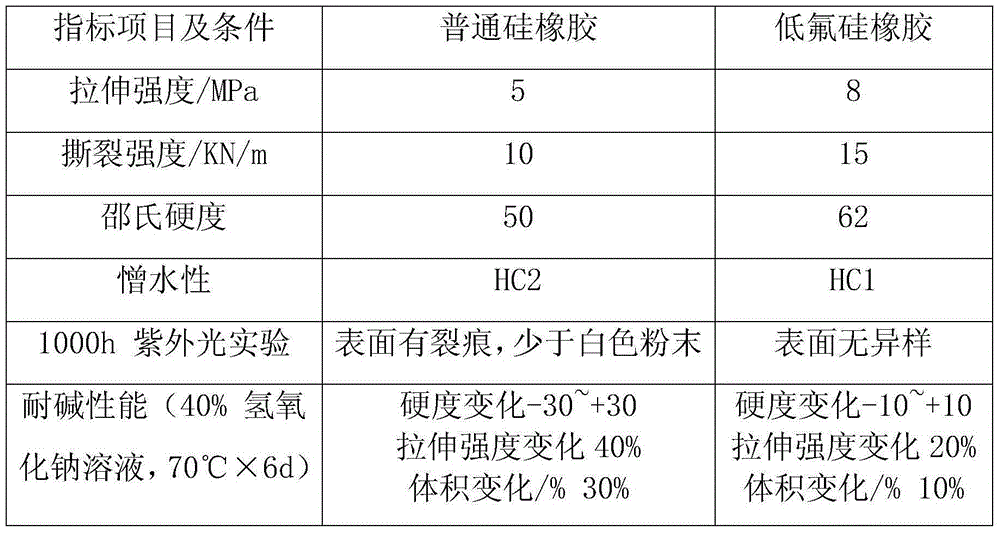

[0013] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are a...

Embodiment 2

[0017] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 9 parts of precipitated white carbon black, 25 parts of flame retardant, 7 parts of zinc stearate, 6 parts of activated magnesium oxide, and 5 parts of iron oxide powder in a double-roller Mixing uniformly in the kneader to obtain a uniform masterbatch, the flame retardant is a composite of aluminum hydroxide and antimony trioxide, the composite molar ratio of aluminum hydroxide and antimony trioxide is 3:1, and the The masterbatch was banburyed in a kneader at 170°C and a vacuum of -0.09MPa for 20min, then 0.3 parts of dicumyl peroxide was added, banburyed again at 200°C for 5h, and left overnight to obtain the low-fluorine Silicone Rubber.

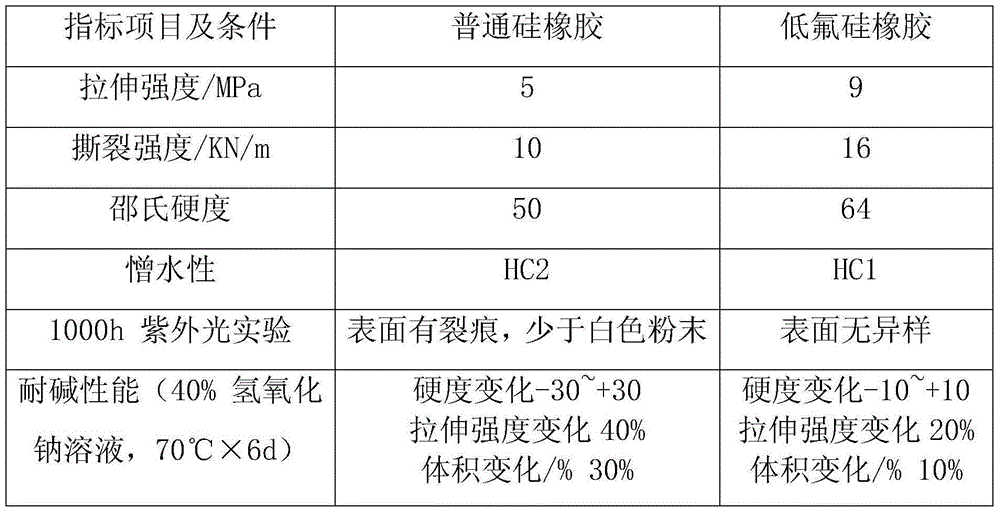

[0018] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are as follows:

[0019] Table 2 is the performance parameter of the low fluorine silicone rubber prepared by embodiment

[0020]

Embodiment 3

[0022] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 8 parts of precipitated white carbon black, 20 parts of flame retardant, 5 parts of zinc stearate, 4 parts of activated magnesium oxide, and 3 parts of iron oxide powder in a double-roller Mixing uniformly in the kneader to obtain a uniform masterbatch, the flame retardant is a composite of aluminum hydroxide and antimony trioxide, the composite molar ratio of aluminum hydroxide and antimony trioxide is 2:1, and the The masterbatch was banburyed in a kneader at 170°C and a vacuum of -0.09MPa for 15min, then 0.2 parts of dicumyl peroxide was added, banburyed again at 200°C for 4h, and left overnight to obtain the low-fluorine Silicone Rubber.

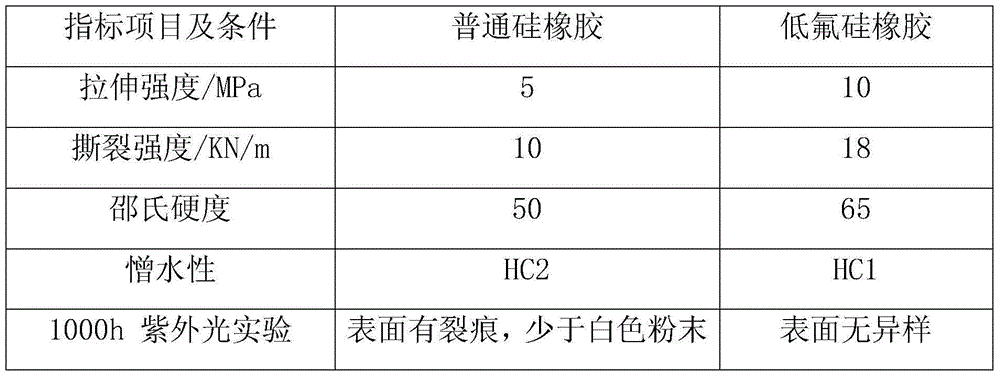

[0023] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are as follows:

[0024] Table 3 is the performance parameter of the low fluorine silicone rubber prepared by embodiment

[0025]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com