A method and device for treating and reusing sewage at the top of a distillation unit

A technology for sewage treatment and distillation equipment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc. Difficulty and other problems, to achieve the effect of reducing load and corrosion, significant processing effect, and reducing processing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

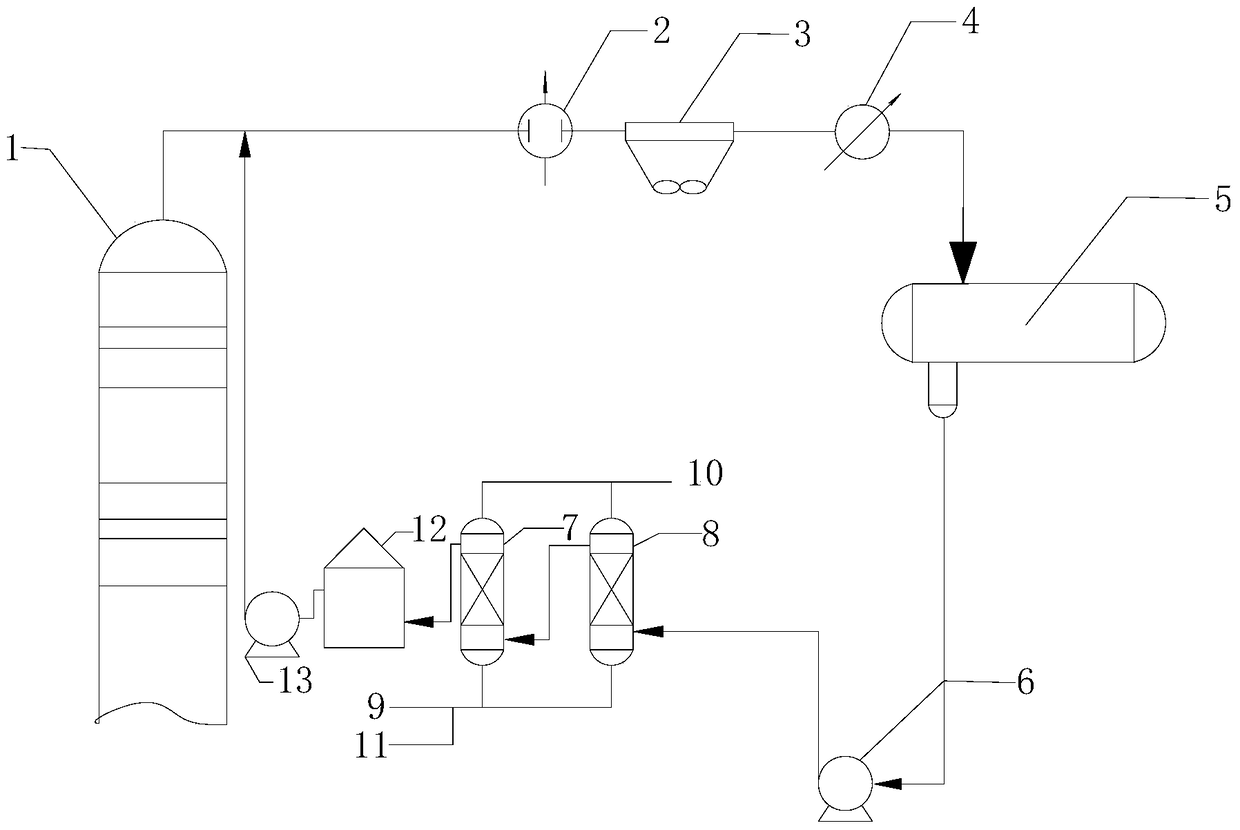

[0049] A method for treating and reusing sewage at the top of a distillation unit, comprising the following steps:

[0050] The oil and gas at the top of the atmospheric tower come out of the top of the distillation tower, and after heat exchange, air cooling, and water cooling, the sewage at the top of the distillation tower is obtained;

[0051] Pass the distillation tower overhead sewage into a zeolite filter for filtration. The filter medium of the zeolite filter is a mixture of zeolite and activated carbon. The weight ratio of the zeolite and activated carbon in the zeolite filter to the treated distillation tower overhead sewage is 0.5g: 50ml ;The zeolite filter adopts the continuous dynamic adsorption of the adsorption column, the adsorption temperature is 40℃, and the adsorption time is set at 50min;

[0052] The water filtered by the zeolite filter is passed into the macroporous strong alkali mixed anion exchange resin for filtration. The space velocity of the macropo...

Embodiment 2

[0057] A method for treating and reusing sewage at the top of a distillation unit, comprising the following steps:

[0058] The oil and gas at the top of the atmospheric tower come out of the top of the distillation tower, and after heat exchange, air cooling, and water cooling, the sewage at the top of the distillation tower is obtained;

[0059] The sewage at the top of the distillation tower is filtered through a zeolite filter. The filter medium of the zeolite filter is zeolite. The weight ratio of the weight of the zeolite in the zeolite filter to the sewage at the top of the distillation tower is 1g:50ml; the zeolite filter adopts an adsorption column Continuous dynamic adsorption, the adsorption temperature is 60°C, and the adsorption time is set at 30 minutes;

[0060] The water filtered by the zeolite filter is passed into the macroporous strong alkali mixed anion exchange resin for filtration, and the space velocity of the macroporous strong alkali mixed anion exchan...

Embodiment 3

[0065] A method for treating and reusing sewage at the top of a distillation unit, comprising the following steps:

[0066] The oil and gas at the top of the atmospheric tower come out of the top of the distillation tower, and after heat exchange, air cooling, and water cooling, the sewage at the top of the distillation tower is obtained;

[0067] The sewage at the top of the distillation tower is filtered through a zeolite filter. The filter medium of the zeolite filter is activated carbon. The weight ratio of the weight of the activated carbon in the zeolite filter to the sewage at the top of the distillation tower is 2g:50ml; the zeolite filter adopts an adsorption column Continuous dynamic adsorption, the adsorption temperature is 25°C, and the adsorption time is set at 60 minutes;

[0068] The water filtered by the zeolite filter is passed into the macroporous strong alkali mixed anion exchange resin for filtration. The space velocity of the macroporous strong alkali mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com