Method for preparing local soft solder coating on surface of aluminum alloy

A technology of aluminum alloy surface and solder, applied in the field of materials, can solve the problems of pollution, low potential of aluminum electrodes, easy bubbling, etc., and achieve the effects of reducing production cost, reducing production cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

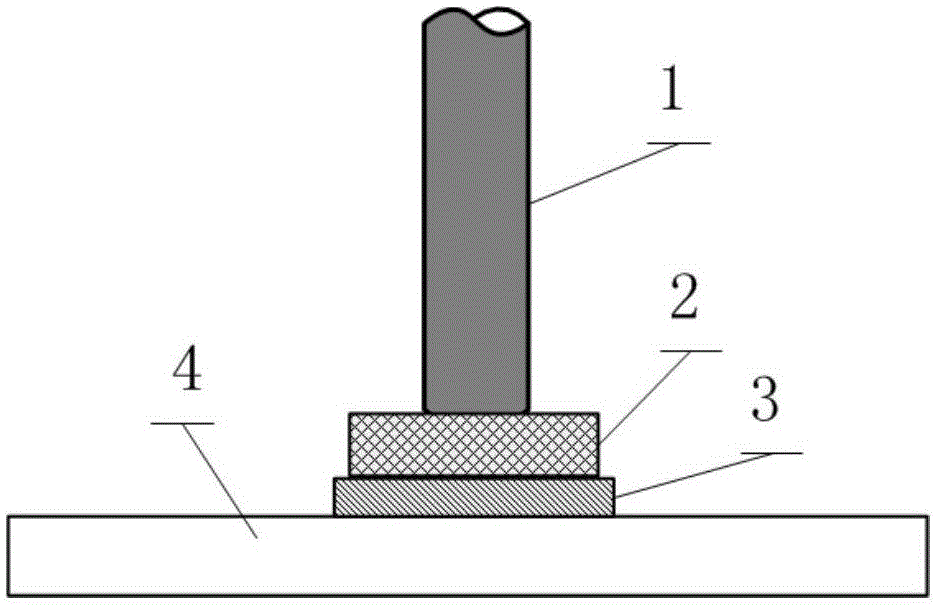

[0028] Such as figure 1 As shown, the local coating of aluminum or aluminum alloy in this embodiment is realized according to the following steps: 1. After decontaminating and cleaning the parts of the aluminum alloy that need to be coated, lay tin foil with an area of 15×15 mm and a thickness of 300 μm on the surface. 2. Place the titanium-based alloy ultrasonic transmission medium (the lower surface area is 20×20mm) connected to the ultrasonic welding head on the tin foil and heat it to 250°C. 3. Apply a longitudinal ultrasonic wave with a frequency of 30 kHz and an amplitude of 5 μm. After ultrasonic treatment for 15 s, remove the ultrasonic conducting medium, use hot air leveling equipment to remove excess tin, and place the aluminum alloy in air to cool to room temperature.

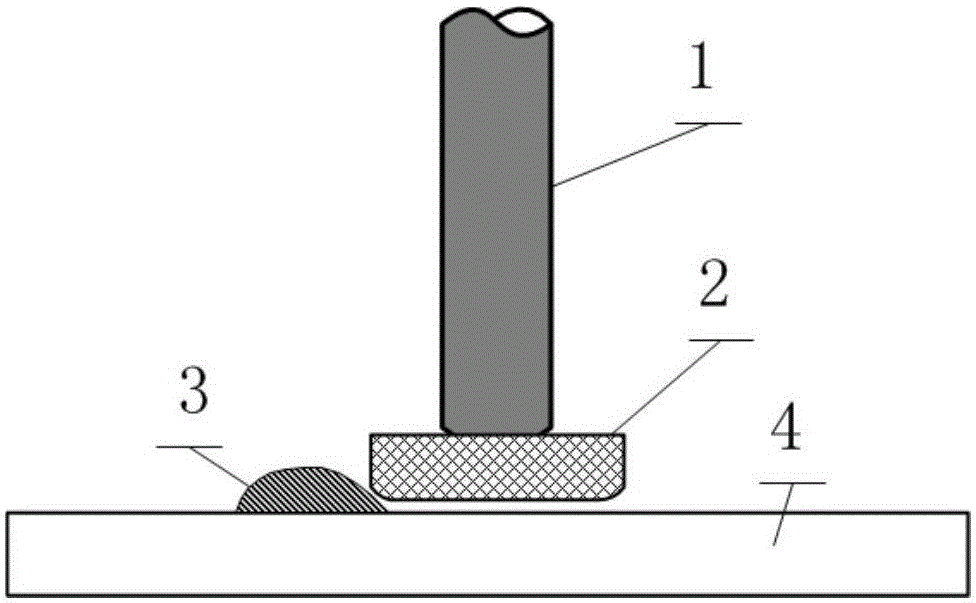

[0029] Macroscopically inspect the coating, and the coating surface is clean and free of voids. Through EDS line scanning, it can be seen that tin and aluminum alloy form a good metallurgical bond...

specific Embodiment approach 2

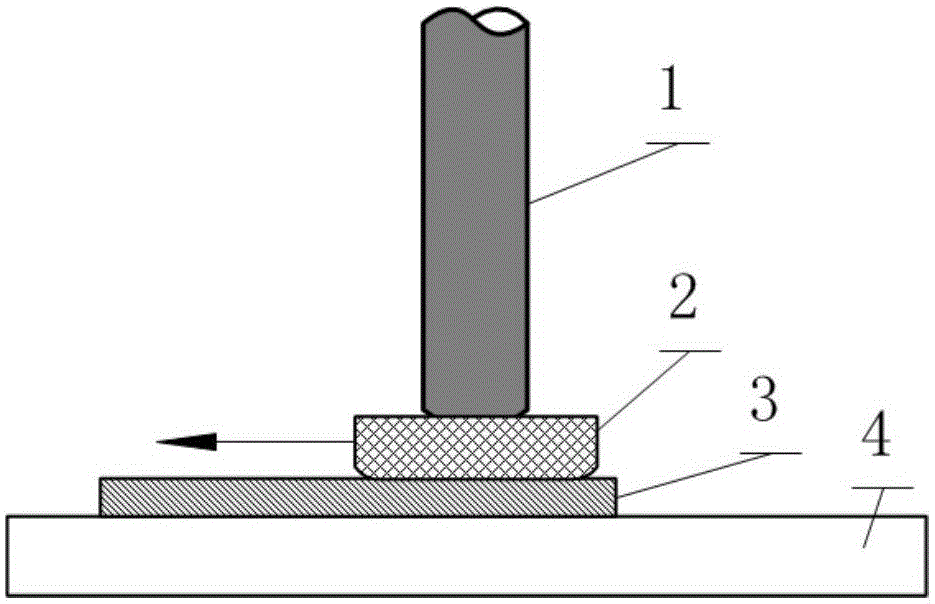

[0030] Such as figure 2 As shown, the local coating of aluminum or aluminum alloy in this embodiment is realized according to the following steps: 1. After decontaminating and cleaning the parts of the aluminum alloy that need to be coated, lay tin foil with an area of 25×25 mm and a thickness of 300 μm on the surface. 2. Place the ceramic ultrasonic conducting medium (the lower surface area is 10×10mm) connected with the ultrasonic welding head on the tin foil and heat it to 250°C. 3. Apply a longitudinal ultrasonic wave with a frequency of 30kHz and an amplitude of 5μm. After ultrasonic treatment for 10s, move the ultrasonic device in parallel at a speed of 0.05m / min, so that the ceramic medium can cover the entire area to be plated at a slow speed, and stay in the final position for 10s. . Remove the ultrasonic conductive medium, use hot air leveling equipment to remove excess tin and place the aluminum alloy in air to cool to room temperature.

specific Embodiment approach 3

[0031] The difference between this embodiment and the first embodiment is that a longitudinal ultrasonic wave with a frequency of 20 kHz and an amplitude of 10 μm is applied, and the ultrasonic treatment is performed for 8 s. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com